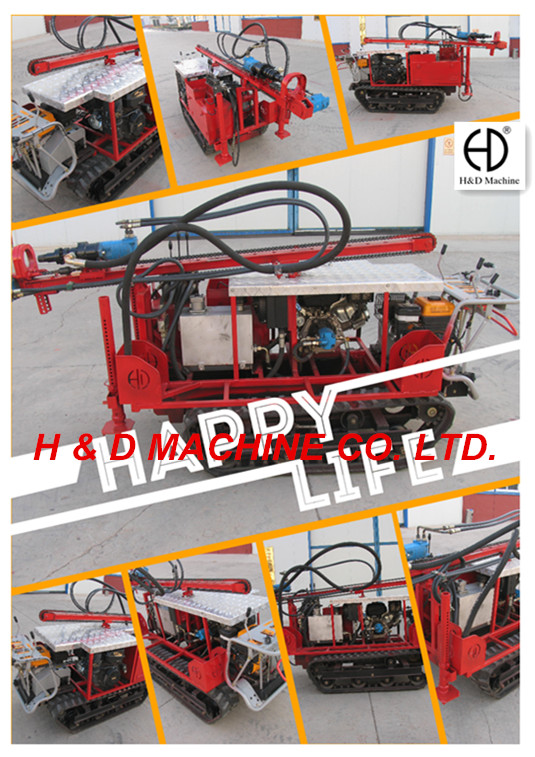

HD-C20 MECHANICAL DRIVE CRAWLER DRILLING RIG

HD-C20 MECHANICAL DRIVE CRAWLER DRILLING RIG

Our drilling rigs are made strictly according to general industrial design standards and fields requirements. Optional methods will meet kinds of drilling formation in field and satisfy our clients. The most advantage is that our independent R&Ddepartment allows us to do OEM, so we will design and modify the drilling rig as per clients’ requirements according to drilling field formation situation.

Features of drilling rig:

- With different combination methods, the drilling rig has kinds of functions as air drilling, air hammer drilling, auger drilling, mud drilling for seismic prospecting, mine survey, geologic framework investigation etc. such drilling projects. It is suitable for field formation like marsh, beach, snow, grasslands, snow,forests,swamps, the seasonal farmland etc.

- We select the mature products of well-known specialized company of the world, for example: Kubota, HAWE, STAUFF, Eaton and so on, to ensure optimal performance and high reliability of drilling rig. Hydraulic driven achieves simple operation and easy maintenance.

- The chassis is mechanical gear shift type.It has high speed, low ground pressure, strong adaptabilityto groundsurface. It meets the demand of vegetation protectionand green construction. And reduces numbers of operator and the safety risk.

- New model design of power swivel that circulation drilling fluid and bearing chamber are separate reduces damage probability of bearing. Clearance between seals is adjustable, so maintenance interval is long.

- The drilling rig is equipped with the balance valve and relief valve to ensure steady going up & down with load, improves the reliability and safety of drilling rig.

- It is also equipped with safety and warning mark to meet the requirement of H.S.E. and improves the level of security of the rig effectively and reduces accident rate.

-

Main Specification

Drilling method

Depth (m)

Pipe(diameter*length) (mm)

The method of throwing dynamite

Hole diameter

Mud drilling (With mud pump)

20

φ60*1500

Aftermoving the tools

3”,3.5”

Air (Hammer) drilling (With compressor)

15

φ60*1500

Aftermoving the tools

Φ82 mm

Casingdrilling (With compressor and Hammer)

10

φ50*1500 +

φ102*1500

Center of the casing

Φ102 mm

Power swivel

Rating torque

540 N.m

Rated speed

0~135 r/min

Hoisting/Push-down system

1000 kg

2 kN

Send product request

Other supplier products

| Rock wool production line | The rock wool production line mainly uses slag basalt, limestone or dolomite and coke as raw materials. To control the environmental pollution, red... | |

| Rock wool board production line | Equipment composition i.Raw material system 1.Feeding system 2.Automatic proportioning machine 3.Control cabinet (PLC is adopted) 4.Feeding machine... | |

| Glass Wool Production Line | We can design and manufacture glass wool production line with annual capacity: 2000 tons, -20000 tons. Our assembly: single production line with si... | |

| Rock Wool Production Line | We provide equipments according to clients' requirement. Such as rock wool production line with tank furnace, rock wool production line with cupola... | |

| Glass wool production line | Producing process: Gas pond kiln----Spinning machine----Wool collection machine-----Wool-collecting barrel -----Wool-allocation conveyer (8 meters)... |

Same products

| Static Type Pedestal Boom System | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Key features include: · Choice of 24 Rock Breaker Boom System models with a horizontal re... | |

| YZH Pedestal Breakers System | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Our Pedestal Breakers indispensable in Mines and Quarries. They are suitable for horizontal axis ... | |

| OEM China Diamond Grinding Shoe Suppliers and Manufacturers | Seller: Xiamen ChinShine Industry and Trade Corporation | Diamond grinding shoes are essential tools in the construction and flooring industries, offerin... | |

| High Performance Automatic Milk Mineral Water Bottle Drink Filling Machine for Sale | Seller: Professional Hebei Shenghui Pump Company | It is mainly used for bottling and dispensing of aqueous liquids and can be applied to containers... | |

| New Design Fully Automatic Vertical Paste Sachet Sealing Packing Machine | Seller: Professional Hebei Shenghui Pump Company | Automatic paste sachet packing machine is designed to automate the process of filling and packagi... |