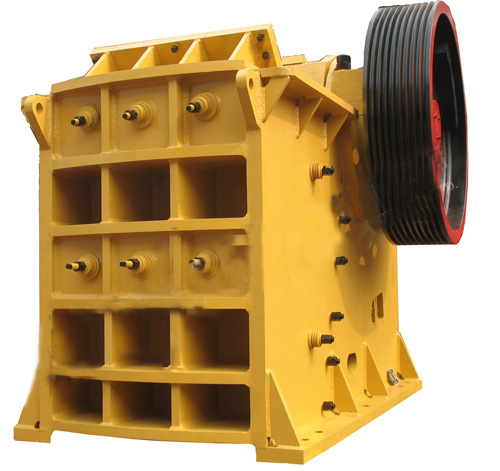

Jaw Crusher

1.ID, and highest-level raw material is used.

2. Central lubricating device are installed on the machine, so the bearing is easy to be lubricated.

3. Adjustment of the discharge part is more convenient.

The adjustment methods: gasket adjustment, hydraulic assistant adjustment, wedge block and wedge hydraulic adjustment.

4. More advanced movable jaw assembly lengthens life of crusher.

Movable jaw assembly is made from cast piece with high-quality, is driven by two large flying wheels which are made from cast steel. Moreover, heavy eccentric shaft is processed by forged mold. All of these make the JC series jaw crusher extremely reliable.

5. Integral cast steel structure is adopted for bearing seat. Integral cast steel bearing matches well with the crusher frame, at the same time, radial strength of the bearing seat is highly strengthened. However, the separate bearing seat does not have this advantage.

6. Finite element analysis technology is adopted to make the crusher much stronger.

7. Crusher chamber adopts "V" structure which could make actual feed width comply with the nominal one.

Other supplier products

|

|

Vibrating Feeder |

Smooth vibration, reliable operation, long service life, low noise, low power consumption, easy to adjust, simple structure, easy to install, light... |

|

|

Belt Conveyor |

Large transportation amount ,simple structure,convenient maintance ,components standardization. |

|

|

Vertical Shaft Impact Crusher |

1. Simple structure and low operating cost;

2. High crushing ratio with low consumption;

3. Function of fine crushing and crude grinding;

4. ... |

|

|

Vibrating Screen |

1.It uses eccentric block to produce strong exciting force.

2.Crossbeam and the main body of the screen are connected with high strength screw bo... |

|

|

Cone Crusher |

1.Combining optimal designing of chamber type with applying reasonable speed and stroke, to make this kind of machine does more work with the same ... |

All supplier products

Same products

|

|

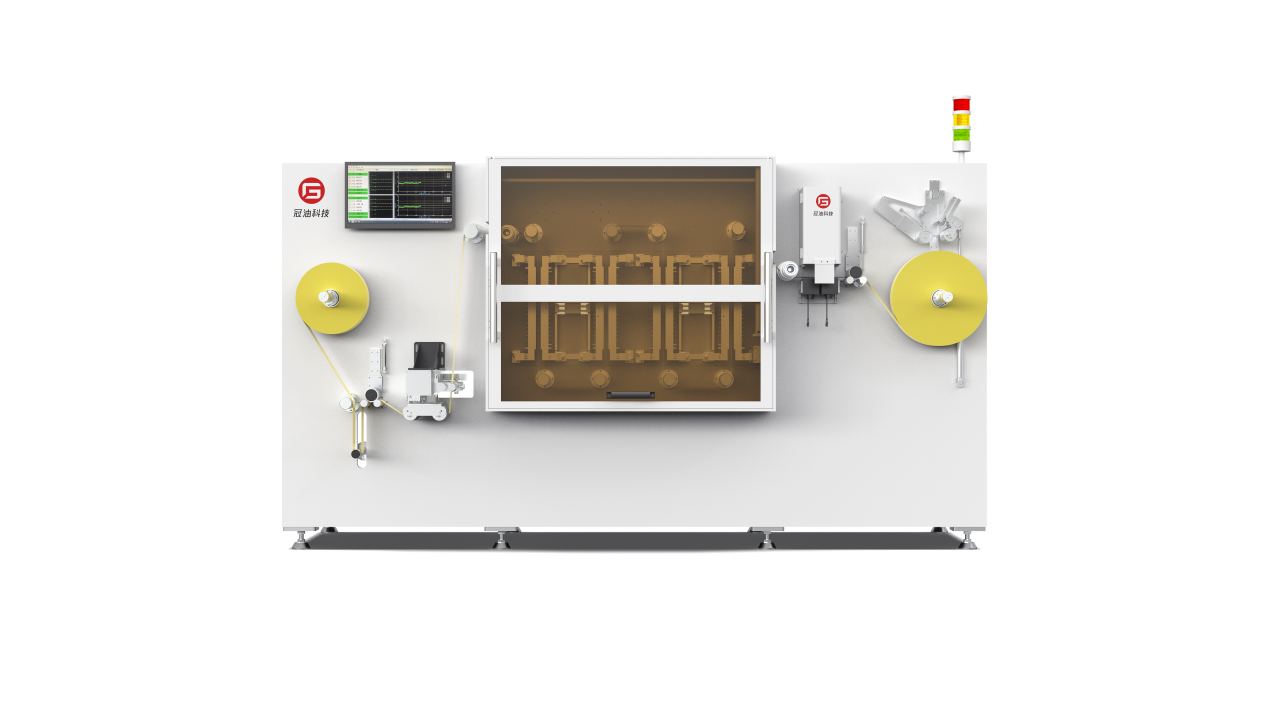

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |