plastic granulator

70kg~450kg hour capacity. Applicable to all types of dry film is compatible with universal nozzle for plastic materials raw material type LDPE LLDPE HDPE PP non-woven cloth ...Preparation of raw material, manual sorting. To save power and improve the efficiency of production, raw materials should not be included, or as little moisture as possible. Feeding method for oblique deep bucket feeding. To ensure workers ' safety, Two-stage dual exhaust, dual-channel intelligent temperature control, automatic precise temperature control, avoid the color cast, not plasticized, air holes, and so on.Cutting machine is made of stainless steel and chrome plating process, pneumatic, import of SKD II material cutting tool, ensure that the cuts neatly, pellet. When the particles with high water requirements, optional closed-loop dual moisture absorption, dehydration rate can reach above 95%, electric power from the 110kw~180kw, (power coefficient for 0.3~0.55). Weight 5t~11t. Display recommended 7 font display in the form. Ground level is usually the (5.5m~7m) * (8m~12m). Fixed number of 2~3 people/plastic granulator operation class.The machine factory, 1:1 production by commissioning. Customers factories required to prepare the corresponding main electricity, compressed air, cooling circulation water.

Other supplier products

|

|

plastic granulator |

70kg~450kg hour capacity. Applicable to all types of dry film is compatible with universal nozzle for plastic materials raw material type LDPE LLDP... |

All supplier products

Same products

|

|

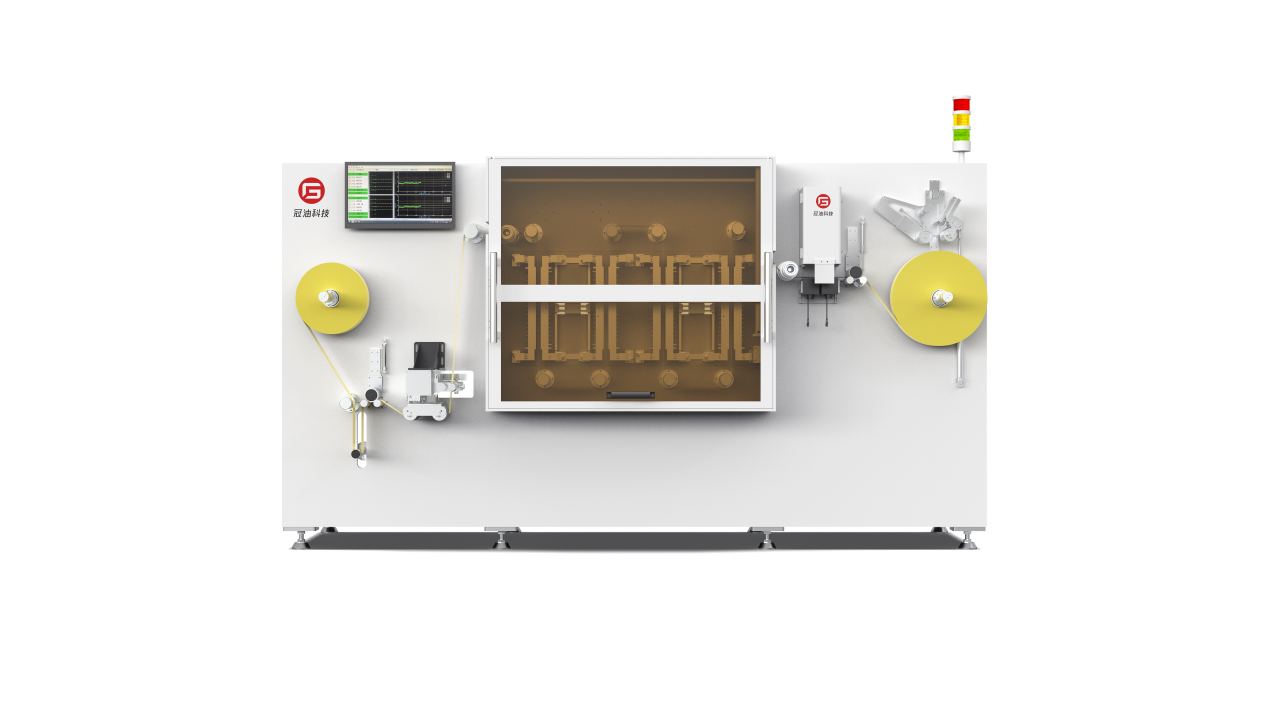

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |