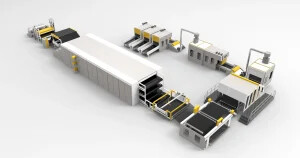

Middle speed Cross lapper

Cross lapper, it's very common web formation machine and applicable for diverse nonwoven productions.

Functionality & application:

1. Fiber web to be piled up and delivered out in another direction altering 90 degrees. In this way, it converts the fiber web sheet come to be overlapped form.

2. With the ability to adjust the thickness, weight and evenness of end product. It’s required for different nonwoven productions like needle punching, thermal bonding, chemical bonding, spunlace, etc.

Features and Advantages

1. Synchronous and frequency conversion controlled with position switch.

2. Subdivision speed control by PLC and servo motor to improve products uniformity further

2. Each lapping belt driven by independent transmission.

3. Clamping infeed lattice with anti-static apron, steady reciprocated carrier.

4. Easy operation and maintenance

Specifications:

|

Category: |

Middle Speed Cross lapper |

|

Input width: |

≤2500mm |

|

Output width: |

2500mm~9000mm |

|

Infeed speed: |

≤40m/min |

|

CV control: |

≤7% or ≤5%(by servo motor) |

Mechanical details:

1) Input width and output width made to order

2) Reciprocation carrier driven by timing belt

3) Reciprocation speed is subdivision controlled by PLC

4) Input, lapping, is frequency controlled with position switches

Quality:

* Selected component suppliers : Siemens ; Siemens Beide ; TWB; NSK; CHINT; etc

* TQM for entire manufacturing process and trial testing.

* Certificate : ISO9001 & CE

Send product request

Other supplier products

| New products Nonwoven Production Line Nonwoven Machine Filter Fabric Needle Punching Production Line | Sail Nonwoven Machinery Co., Ltd is a professional and leading nonwoven machinery manufacturer of China. Sail has shared a good reputation among ou... | |

| Middle speed Cross lapper | Cross lapper, it's very common web formation machine and applicable for diverse nonwoven productions. Functionality & application: 1. Fiber web... | |

| Main opener(New) | Functionality & application:1.Handy pulling design to opening cover case, easy cleaning inside 2.Special air duct design largely reducing fiber... | |

| Car interior felt production line | Applications: For the production ofhighquality felt as car interiorsuch as car roof felt, car trunkfelt. Reference product specification:2000mm -... | |

| Bale opener (New) | Bale opener as a kind of fiber opening machines. It works to open fibers and quota fiberinput quantity by auto weighting system, meanwhile raw mate... |