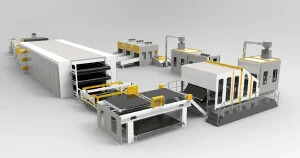

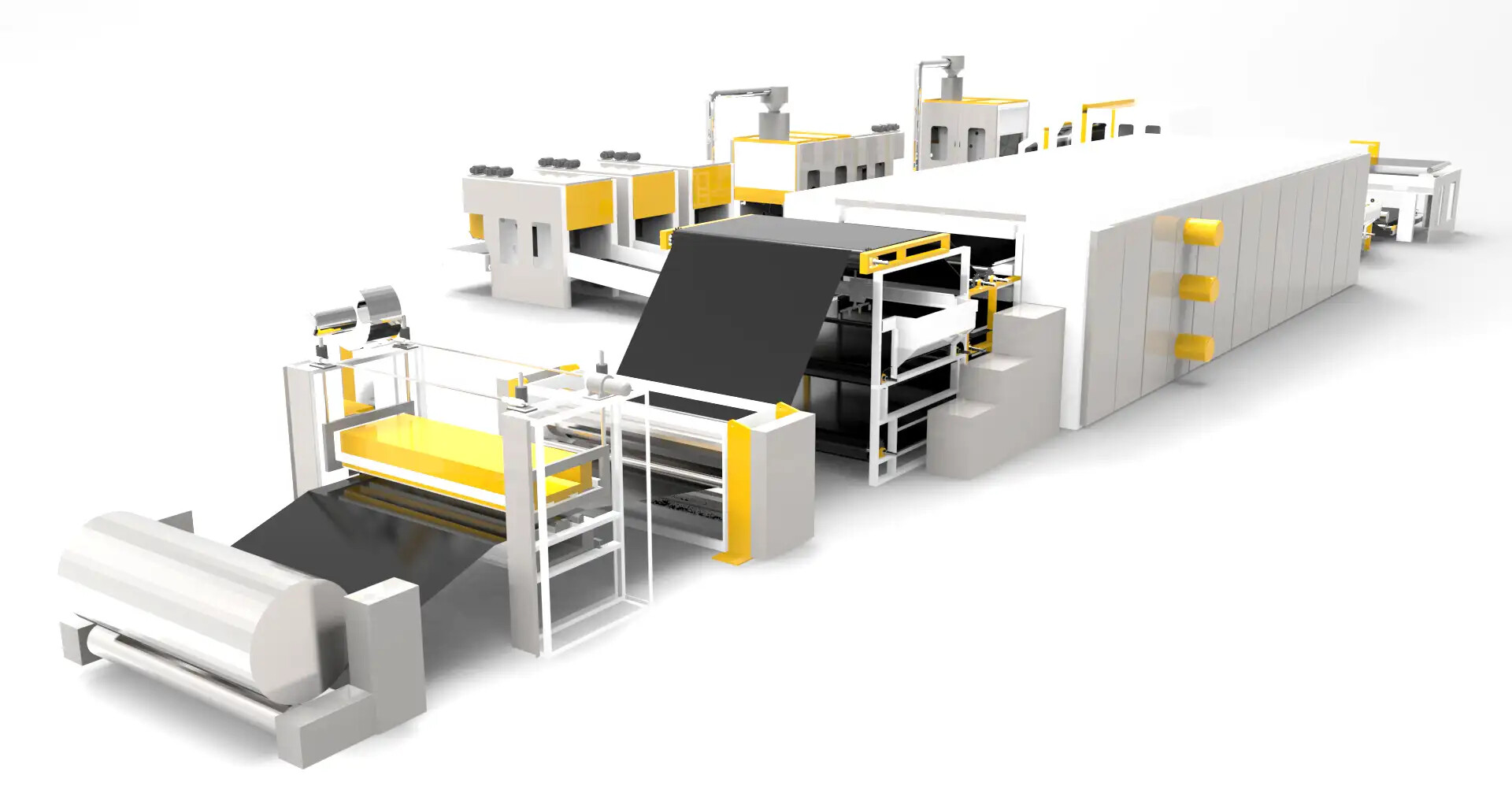

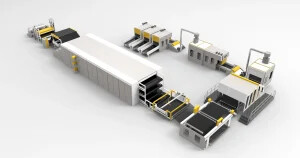

ALLQ--6500mm Asphalt Geotextile Needle Punching Nonwoven Production Line

The ALLQ--6500mm Asphalt Geotextile Needle Punching Nonwoven Production Line is a highly advanced system designed for producing durable, high-performance asphalt-coated geotextile materials. By integrating the Nonwoven fabric production line technology, it ensures consistent product quality and high production efficiency.

Key Components of the Production Line:

-

Raw Material Feeding System: Handles the input of geotextile fabric and asphalt.

-

Coating Unit: Evenly applies the asphalt coating.

-

Drying/Curing Chamber: Solidifies the asphalt coating properly.

-

Cooling Section: Reduces the temperature of the finished fabric for stabilization.

-

Cutting and Winding Unit: Cuts to specified dimensions and rolls the final product.

-

Control System: Monitors and manages the entire production process for optimal quality.

Production Process:

-

Material Preparation: Feeding geotextile fabric and asphalt into the system.

-

Coating: Even application of asphalt using a specialized unit.

-

Drying/Curing: Moving through the curing chamber to solidify the asphalt layer.

-

Cooling: Cooling to maintain fabric stability.

-

Cutting and Winding: Final processing into rolls.

Quality Control:

-

Thickness and Weight Testing: Ensures asphalt consistency.

-

Adhesion Strength Testing: Verifies bonding between asphalt and fabric.

-

Durability Testing: Assesses UV resistance and chemical stability.

Applications:

-

Road Construction: Prevents reflective cracking.

-

Waterproofing Projects: Used in tunnels, basements, etc.

-

Ground Stabilization: Enhances soil bearing capacity.

Advantages:

-

High Efficiency: Automated Non woven machine lines deliver consistent output.

-

Customization Available: Tailored to meet project-specific needs.

-

Sustainability: Reduces maintenance frequency, increasing longevity.

Maintenance and Safety:

-

Regular machine maintenance extends operational life.

-

Strict adherence to safety protocols protects workers and equipment.

All solutions are provided by Dongyang Aolong Nonwoven Equipment Co. Ltd., a leading manufacturer in nonwoven machinery.

Send product request

Other supplier products

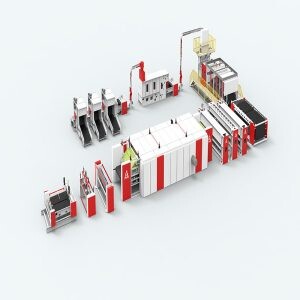

| ALCD--3200mm Nonwoven Chemical-bonded Wadding Oven Non Woven Fabric Making Machine | The ALCD--3200mm Chemical-bonded Wadding Oven is a high-capacity nonwoven machine specially designed for the production of chemically bonded waddin... | |

| ALBJB–2500mm Nonwoven Abrasive Pad / Scouring Pad Production Line With Spray Oven and Dipping Oven | This specialized is designed for the production of abrasive nonwoven fiber pads, widely used in industrial polishing, floor cleaning, and kitchen ... | |

| ALGYB--1000mm Acoustic Panel Nonwoven Fabric Production Line | Key Properties Sound Absorption: High porosity and fiber density enable effective sound absorption, reducing noise levels in various environme... | |

| 2400mm High Strength Large PET Spunbond Nonwoven Machine | AL-RPET Spunbond Nonwoven Machine Parameters: Raw Material: Width of finidhed fabric: Process Speed: web weight: Annu... | |

| AL--1100mm PET Needle Punching Oven Nonwoven Fabric Scrubbing Pad Making Machine | The AL--1100mm PET Needle Punching Oven Nonwoven Fabric Scrubbing Pad Making Machine is designed for the high-efficiency production of abrasive cle... |