WFI TANK/SKID

The distribution system is the core unit of the whole pharmaceutical water system, and its main function is to ensure that the pressure, flow and temperature delivered to the process pipeline meet the process production requirements. The system uses online monitoring instruments such as flow, pressure, temperature, conductivity and TOC to conduct safety performance, real-time monitoring and trend analysis of water quality, and effectively control the load of microorganisms in water through periodic disinfection or sterilization. In addition, sampling valves shall be installed on the water supply starting point, water pipeline and end pipeline of the entire distribution system for water quality sampling. The whole system is mainly composed of inverter, exchanger, sampling valve, diaphragm valve, sanitary pipe fittings, online monitoring instrument and other supporting control systems.

What is a WFI skid?

WFI skid stands for "Water for Injection skid." It is a pre-engineered and pre-assembled system used in pharmaceutical manufacturing to produce Water for Injection (WFI), which is a type of highly purified water used in the production of injectable drugs.

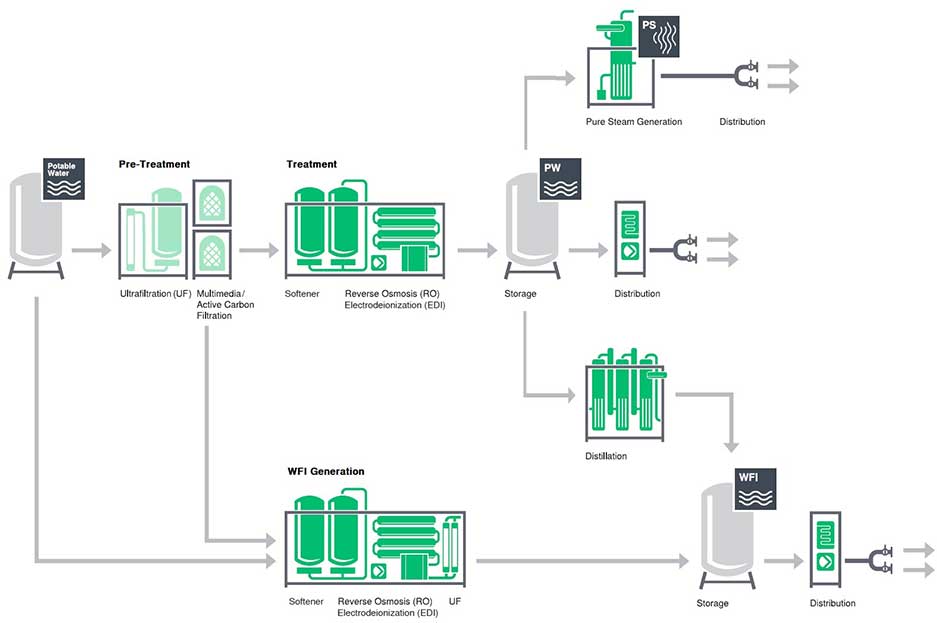

The WFI skid typically consists of a series of components that work together to produce and distribute WFI in a safe and controlled manner. These components may include a multi-stage water purification system, a distillation unit, a storage tank, a distribution pump, and various sensors and controls to monitor and maintain water quality.

The WFI skid is designed to meet the strict regulatory requirements for pharmaceutical manufacturing, including compliance with the United States Pharmacopeia (USP) and European Pharmacopoeia (EP) standards. Its use can help pharmaceutical companies ensure the safety and purity of their injectable drug products, and streamline their production processes.

WFI Skid Advantages

The correct design of the storage and distribution system is crucial for the success of the injection water system. Our injection purified water storage and distribution system can accurately achieve the following three objectives: to ensure that the quality of injection water is within the scope of the pharmacopeia requirements; Annotate

Injecting water is transported to each process usage point at a flow rate, pressure, and temperature that meets production requirements: ensuring a reasonable allocation of initial investment and operating costs.

How Does PW WFI Tank/Skid Works?

Water for injection storage and distribution systems should be periodically sterilized at the temperature of ≥ 121 ° C. The WFI storage and distribution systems may be sterilized using superheated water or pure steam.

For more informationabout water purification system in pharmaceutical industry,please feel free to contact us!

Send product request

Other supplier products

| Pharmaceutical Water Purification System | The operation and maintenance of equipment shall be monitored and managed according to the requirements of verification and documents. Ensure that ... | |

| Water System for Pharmaceutical Use | Water System for Pharmaceutical Use In the pharmaceutical industry, Biocell provides professional solutions for purified water system, water for i... | |

| WATER PRE-TREATMENT | Based on the quality of different raw water, we are committed to providing customers with customized solutions. Modular design is adopted, with rea... | |

| ELECTRIC CLEAN STEAM GENERATOR | Clean steam generator using electric energy as heating source is referred to as electric heating clean steam generator. The steam generated after t... | |

| RO PLANT WITH EDI | The combination of reverse osmosis and EDI has overcome the deficiency that reverse osmosis effluent cannot be deeply desalted, and further removed... |

Same products

| TOFFON bioproduct freeze dryer TF-LYO-2 | Seller: Shanghai Toffon Machinery Equipment Co., Ltd. | The LYO Biopharmaceutical Freeze Dryer is produced using standardized manufacturing processes, re... | |

| TOFFON freeze dryer TF-LYO-0.5 lyophilizer | Seller: Shanghai Toffon Machinery Equipment Co., Ltd. | LYO Bioproduct freeze dryer is a specialized machine used in biopharmaceuticals to preserve and ... | |

| PHARMACEUTICAL REVERSE OSMOSIS SYSTEM | Seller: Nanjing Biocell Environmental Technology Co., Ltd | PHARMACEUTICAL REVERSE OSMOSIS SYSTEM With RO membrane separation technology as the core, the re... | |

| SANITARY HEAT EXCHANGER | Seller: Nanjing Biocell Environmental Technology Co., Ltd | SANITARY HEAT EXCHANGER The wfi sanitary heat exchanger(sterile double tube plate heat exchanger... | |

| CLEAN STEAM GENERATOR | Seller: Nanjing Biocell Environmental Technology Co., Ltd | CLEAN STEAM GENERATORS The prototype of the clean steam generatorfor humidification is a pure st... |