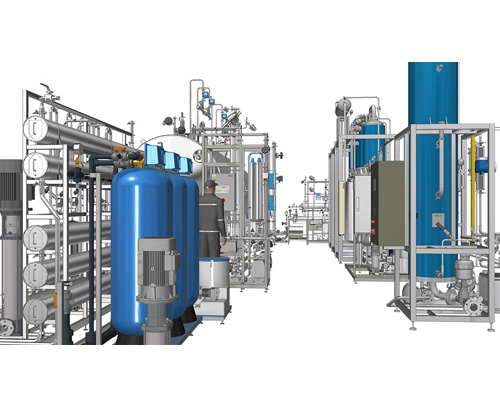

PW/WFI Storage & Distribution Systems

The purified water generation and distribution systemis the core unit of the whole pharmaceutical water system, and its main function is to ensure that the pressure, flow and temperature delivered to the process pipeline meet the process production requirements. The system uses online monitoring instruments such as flow, pressure, temperature, conductivity and TOC to conduct safety performance, real-time monitoring and trend analysis of water quality, and effectively control the load of microorganisms in water through periodic disinfection or sterilization. In addition, sampling valves shall be installed on the water supply starting point, water pipeline and end pipeline of the entire distribution system for water quality sampling. The whole system is mainly composed of inverter, exchanger, sampling valve, diaphragm valve, sanitary pipe fittings, online monitoring instrument and other supporting control systems.

TYPES OF PURIFIED WATER STORAGE AND DISTRIBUTION SYSTEM

PW Tank/Skid

The purified water storage tank is manufactured according to the GMP certification requirements, and the tank body is vertical or horizontal.

WFI Tank/Skid

The storage tank is mainly used for the storage of water for injection. Meet the requirements of GMP for water for injection storage tank.

PW/WFI Skid

The liquid medicine storage and wfi distribution systemincludes a storage part and a distribution part. The design of pharmaceutical water distribution system has various forms, and its basic idea is to minimize the operational risk and microbial risk at a reasonable cost.

GENERAL PRINCIPLES OF PHARMACEUTICAL WATER STORAGE & DISTRIBUTION SYSTEMS

The storage and distribution system of pharmaceutical water includes storage unit, distribution unit and water point pipe network unit. The design of pharmaceutical water distribution system has various forms, and the basic idea is to minimize the operation risk and microbial risk at a reasonable cost.

The storage unit is used to store pharmaceutical water meeting the requirements of the pharmacopoeia and meet the maximum peak consumption requirements of the system. The storage system must maintain the quality of water supply, so as to ensure that the quality of the end use of the product is qualified.

Circulating design is adopted for the pharmaceutical water supply pipeline.The main function of the distribution system is to deliver pharmaceutical water meeting the requirements of the Pharmacopoeia to the process water point, and ensure that its pressure, flow and temperature meet the requirements of process production or cleaning.

The storage and distribution units need to be disinfected regularly to reduce the possibility of microbial breeding.

HOW IS WATER SYSTEM DISTRIBUTED?

01

PW storage and distribution system

PW storage and purified water distribution systemmust be disinfected regularly. Automatic control mode is recommended. The common disinfection methods for purified water storage and distribution system are as follows: 1. Pasteurization; 2. Ozone disinfection

02

WFI storage and distribution system

WFI storage and distribution systems must be sterilized regularly. Automatic control mode is recommended. Common sterilization methods of WFI storage and distribution system are as follows: 1. Pure steam sterilization; 2. Sterilization with superheated water

Want to know more about water purification system in pharmaceutical industry, contact us!

Send product request

Other supplier products

| Purified Water (PW) System | System adopts the latest processes such as reverse osmosis and EDI. A complete set of purified water treatment process has been designed in a targe... | |

| Pharmaceutical Water System | Pharmaceutical Water Systems Water is the most widely used process raw material in the pharmaceutical industry, which is used as the composition... | |

| ELECTRODEIONIZATION (EDI) | EDI is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology and ion electromigration techn... | |

| Pharmaceutical Water Purification System | The operation and maintenance of equipment shall be monitored and managed according to the requirements of verification and documents. Ensure that ... | |

| Pharmaceutical Water Systems In Medical Technology | Biocell provides professional solutions for purified water system, water for injection system, pure steam system, storage and distribution system i... |

Same products

| TOFFON bioproduct freeze dryer TF-LYO-2 | Seller: Shanghai Toffon Machinery Equipment Co., Ltd. | The LYO Biopharmaceutical Freeze Dryer is produced using standardized manufacturing processes, re... | |

| TOFFON freeze dryer TF-LYO-0.5 lyophilizer | Seller: Shanghai Toffon Machinery Equipment Co., Ltd. | LYO Bioproduct freeze dryer is a specialized machine used in biopharmaceuticals to preserve and ... | |

| PHARMACEUTICAL REVERSE OSMOSIS SYSTEM | Seller: Nanjing Biocell Environmental Technology Co., Ltd | PHARMACEUTICAL REVERSE OSMOSIS SYSTEM With RO membrane separation technology as the core, the re... | |

| SANITARY HEAT EXCHANGER | Seller: Nanjing Biocell Environmental Technology Co., Ltd | SANITARY HEAT EXCHANGER The wfi sanitary heat exchanger(sterile double tube plate heat exchanger... | |

| CLEAN STEAM GENERATOR | Seller: Nanjing Biocell Environmental Technology Co., Ltd | CLEAN STEAM GENERATORS The prototype of the clean steam generatorfor humidification is a pure st... |