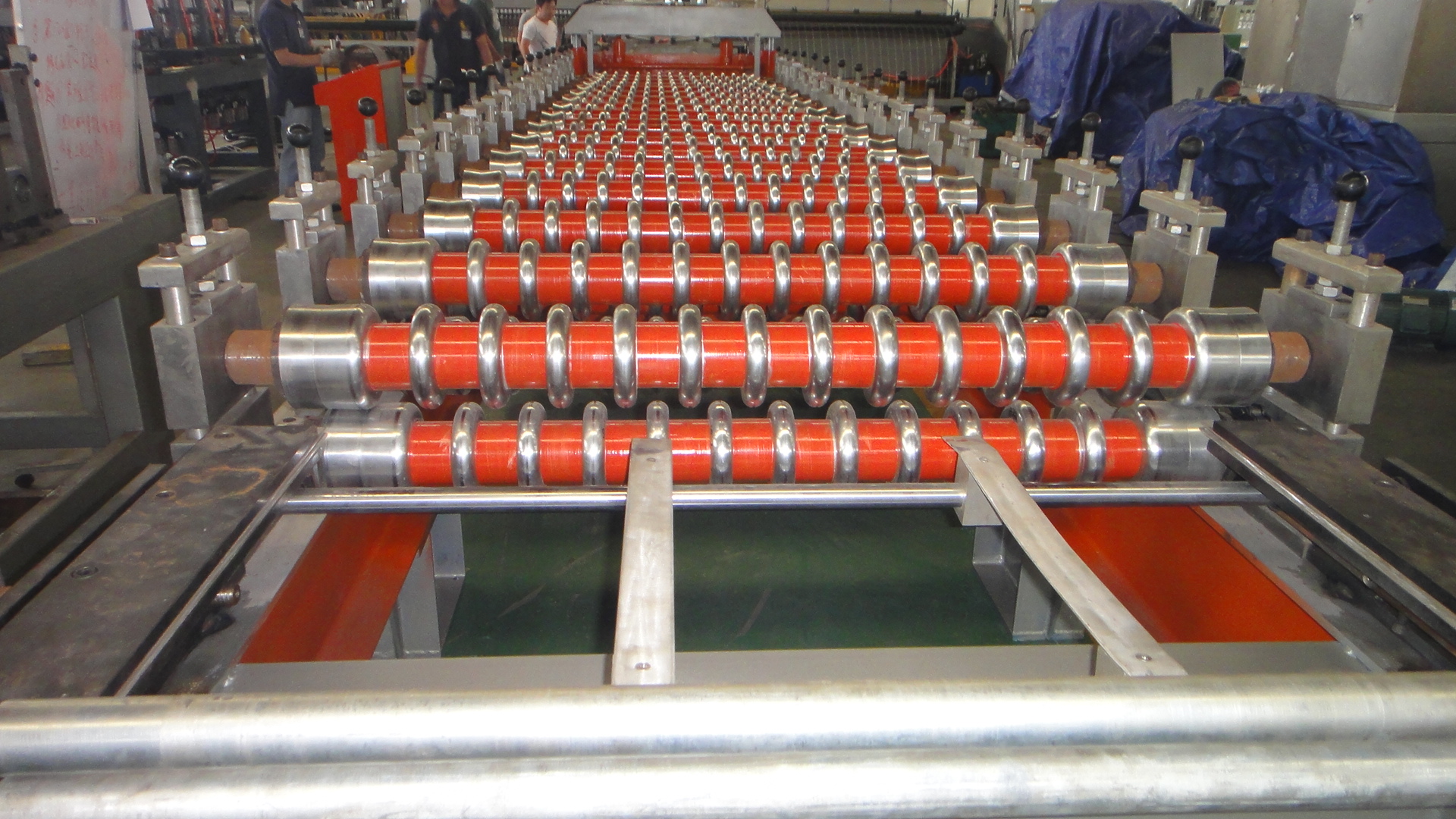

TR 26-170 Wall Panel & Roofing board Roll Forming Machine

All supplier products

- Main technical parameters

1). Thickness of steel coil: 0.8-2.0mm

2). Material: Q235 black sheet

3). Input width: 1000mm

4). Output width: 870mm

5). Total length (from de-coiler to output table): about 14-16M

6). Total weight: about 13T

7). Tolerance of length: 10±2mm

8). Transporting: 1×40ft Container

- Main roll forming machine

1). Machine stand: 350H steel welding structure

2). Guide feed way: side sliding type

3). Structure: wall panel, thickness 14mm

4). Number of stations: 14 stations

5). Main shaft material: 45# steel, O.D.: 90mm, quenching and tempering treatment

6). Roller material: high grade 45# steel, quenching 58-62℃

7). Way of drive: by chain

8). Forming speed: 8m/min

9). Main motor power: 18.5kw

10). Power supply: 380V, 50HZ or at buyer’s requirement, 3-Phase

11). Motor is under the mould, which can save space

12). Dimension (L*W*H): 7.7×1.5×1.8m

1). Material of blade and mould: Cr12MoV steel with quenched treatment 60-62℃.

2). Cutting system: adopt advanced hydraulic cutting system, automatic cut after forming no distortion, waste, high safe factor(main motor stops and then cuts).

3). Cutting type: stop machine cutting.

1).Screen display:Mitsubishi or Siemens touch screen;

2). PLC: Mitsubishi or Siemens;

3). Measure the length automatically;

4). Count the quantity automatically;

5). Length and quantity is controlled by computer, the machine will cut automatically as reaching the set length, the machine can automatic stop;

6). It is easy to adjust the error of length;

7). Meter count way: rotary encoder;

1). YUKEN system, made in China;

2). Power: 7.5KW;

3). Oil pump of hydraulic station: gear pump;

4). Hydraulic cylinder: 100mm;

5). Structure of cutting: size of hydraulic station 55×65×90mm;

6). 1 set of electro valve;

7). The oil pipe can not be welded type (protective of oil leak), treatment of welding spot of total machine.

De-coiler; Roll Forming Machine Unit; Hydraulic Automatic Cutting Unit; Run Out Table;

PLC Control Cabinet; Electrical system; Hydraulic system.

De-coiler→ Feed with guide→ Roll forming→ Hydraulic cutting unit→ Run-out table→ PLC control system

Send product request

Other supplier products

| TR 26-170 Wall Panel & Roofing board Roll Forming Machine | Main technical parameters 1). Thickness of steel coil: 0.8-2.0mm 2). Material: Q235 black sheet 3). Input width: 1000mm 4). Output width:... | |

| Steel coil cut to length line (0.7-6mm)×1600mm | The cut to length line is used to take flat rolled steel or coiled steel unroll it level it and cut it to desired length sheet. Moreover, any speci... | |

| ABE-1.0-1250 Expanded Metal Mesh Machine | Composition of metal expander: The expanded metal mesh machine is composed of framework, driving system, crankshaft connection rod, knife rest, fe... | |

| Corrugated Roll Forming Machine | Specifications: Material: galvanized steel sheet Sheet thickness: 0.15-1.0mm Number of stations: 18 stationsn Rolling speed: about 12-20m/min Stru... | |

| cut to length line for cold rolled steel and hot rolled steel | The cut to length line is used to take flat rolled steel or coiled steel unroll it level it and cut it to desired length sheet. Moreover, any spec... |

Same products

| Security screen mesh | Seller: Sharp Building Materials Sales Department | Diamond mesh is a high-strength, durable stainless steel screen that protects against mosquitoes ... | |

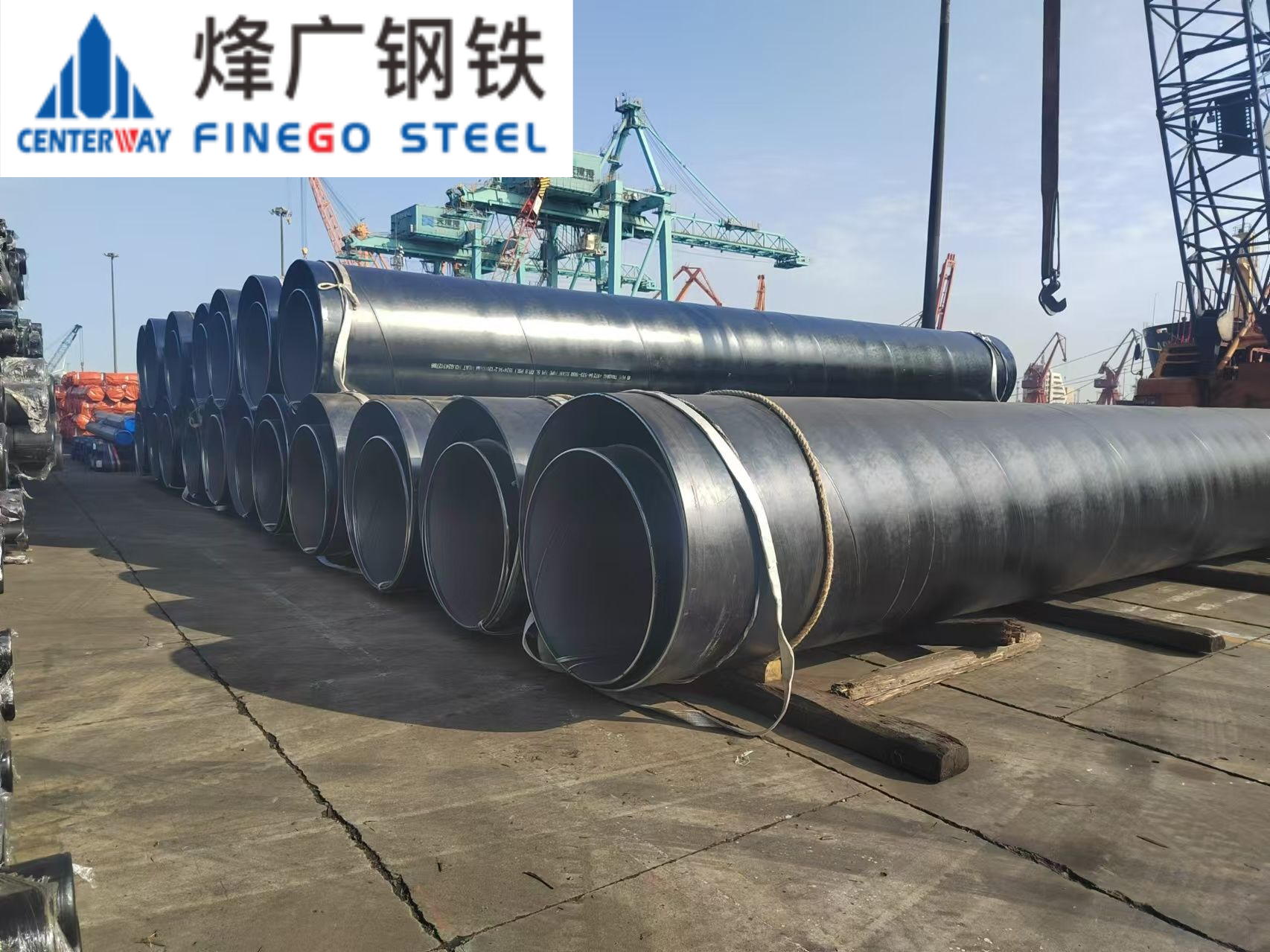

| Steel Pipe | Seller: Finego Steel | Find us: | |

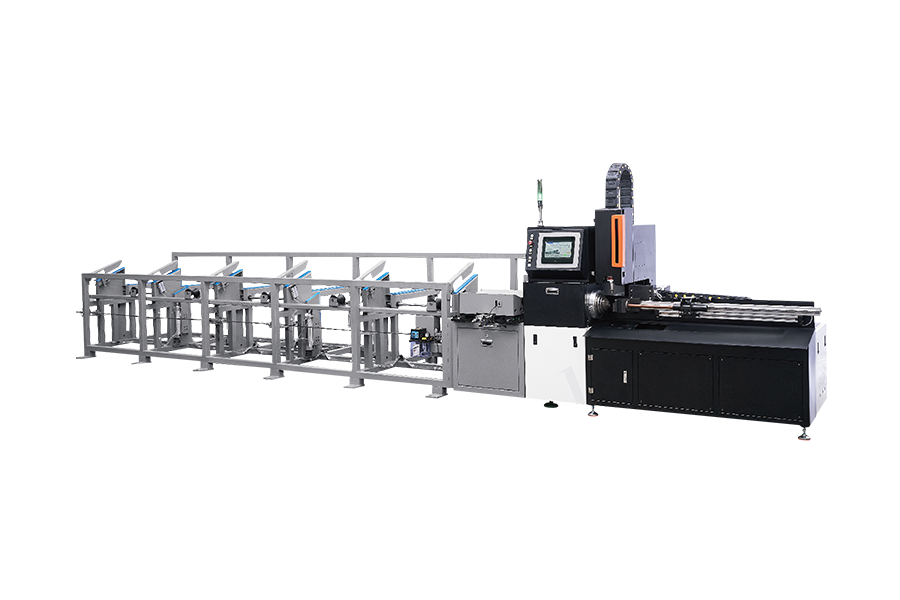

| JH-NC70-Cl3 (2023 Model) Automatic Three-Axis Cnc Laser Pipe Cutting Machine | Seller: Zhejiang Huaqi Information Technology Co., LTD | Introducing the JH-NC70-CL3 AUTOMATIC THREE-AXIS CNC LASER PIPE CUTTING MACHINE, a cutting-edge s... | |

| Railway Hydraulic Rail Gap Adjuster Railroad equipment supplier | Seller: 834406 | 液压导轨间隙调节机 YTF-400II液压导轨间隙调节器适用于43kg--75kg导轨。YTF-400II.液压导轨间隙调节机具有推拉小导轨接头两种功能,推导导轨、拉轨全部可,操作方便,效率高... | |

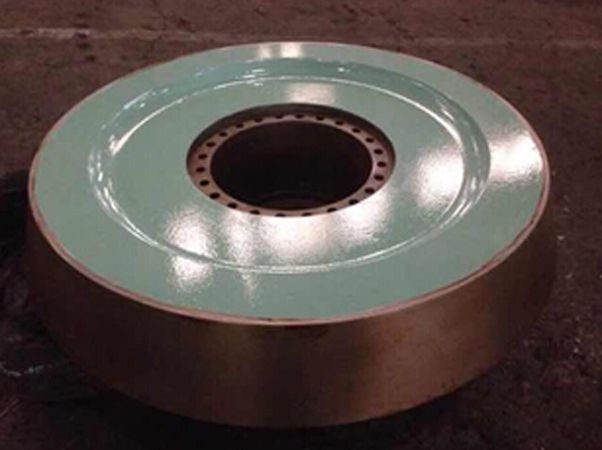

| Thrust Roller | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | CIC is a more than 30-year manufacturer and reputed supplier of thrust roller used in rotary kiln... |