Centrifugal dryer – Spin Dryer

Centrifugal Dryers also called spin dryer. They are typically used when parts are being dewatering and drying in bulk. The parts may be placed into an appropriate size basket which inserted into the dryer. The dryer is then closed, turned on and spins the basket at a very high speed to force any liquid, oil, etc. to leave the part. At the same time the spinning action make parts drying, an heating unit or heating element will be installed to the dryer to make drying process faster and easier.

Send product request

Other supplier products

| Centrifugal barrel tumbling – Harperizer – barrel deburring | Centrifugal Barrel Finishing Machines are high gravity force machines which specifically developed for smaller and precision components; also it is... | |

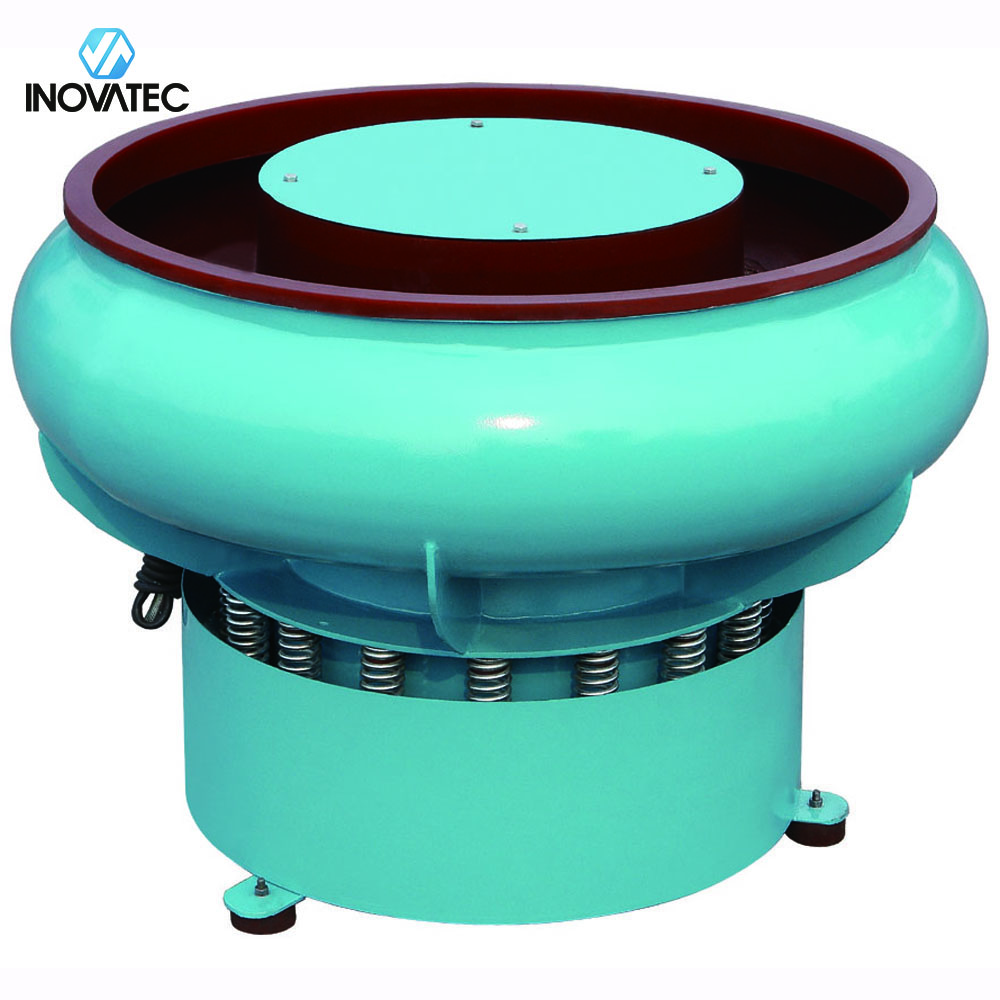

| Vibratory Deburring Machine Tumbler for ball burnishing process | Standard Features: Effective motor position for Excellent Vibration. High tensile bolts and nuts for long service life of motor and machinery. Eff... | |

| Stainless tumbling media | Steel Tumbling Media allows for faster finishing times, eliminates the need for expensive, consumable compound solutions and rust inhibitors, and r... | |

| Vibratory finishing machine for Roto finish | Standard Features: Easy to change the separation deck Heavy-duty long service vibration motor Optional VFD (Variable Frequency Drive to control mo... | |

| walnut tumbling media – crushed walnut shell tumbling media | Walnut shells are used for stamped, formed, or chemically etched thin sheets of brass or beryllium copper.Small screw machine parts and jewelry are... |