centrifugal disc polishing machine – Automatic unloading

Feature:

Processing unit (work bowl)

The processing bowl is casted with DuPont hot moulded PU lining with thickness 20-25mm for long service time and high durability

Disc rotating system

High speed control with optional speed inverter from Bosch Rexroth

Adjustable gap between disc and ring

Water process system

Compound/water dosing system available with tap

PLC touch screen control with Siemens optional

Rigid machine construction

Working principal:

The rotating disc with speed 60-250 RPM pushes the media and components mixture upward to the wall of processing bowl and downward to the processing bowl centre. With reduced acceleration force and enhanced gravity force mixture slides back down to the disc where it is again accelerated. Depending on disc rotation speed, the water level as well as media/compound combination, the finishing applications vary from fast grinding to super fine mirror polishing.

The high energy centrifugal disc finishing machine offer an productivity 10-30 times higher compared with conventional vibratory finishing process.

Send product request

Other supplier products

| Ceramic tumbling media – RS ceramic media tumbler media | RS ceramic grinding media is produced by mixing porcelain, kaolin,clay, river clay together with brown alumina oxide abrasives. The wet material i... | |

| Zero Gap Centrifugal Disc Finishing Machine Otec Design CF series | Feature: Highly user friendly The rotational speed, machine running time (forward/backward respectively), compound dosing as well as other process... | |

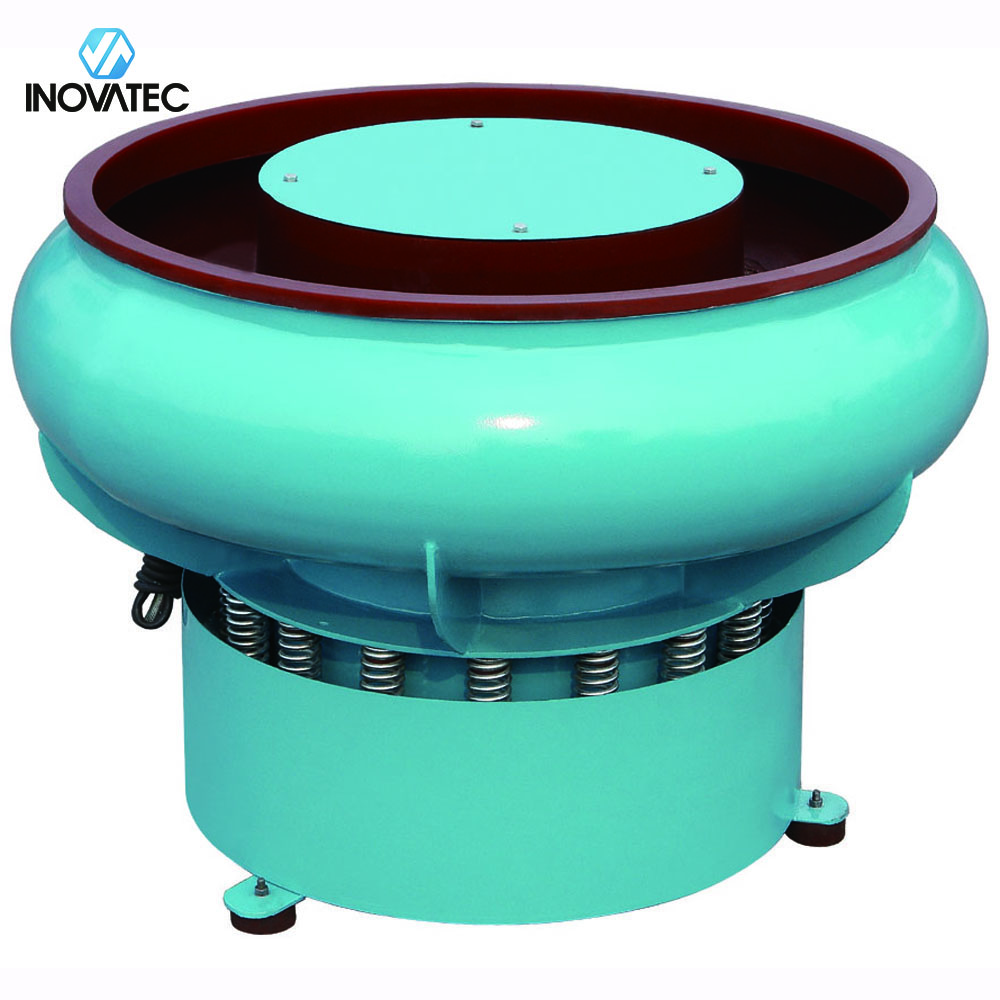

| Vibratory Deburring Machine Tumbler for ball burnishing process | Standard Features: Effective motor position for Excellent Vibration. High tensile bolts and nuts for long service life of motor and machinery. Eff... | |

| Centrifugal barrel finishing machine – Tumbling Barrel – barrel process | Feature User friendly Easy maintenance High-precision finishing operation Short finishing time Ultra-high performance machine for finishing ap... | |

| Vibratory dryer with heating element – Vibratory drier | FUNCTIONAL PRINCIPLE The vibratory dryer generate gentle movement of parts through corn cob or maize During vibratory moisture on surface of parts ... |