DIE CASTING

Die casting can be divided into: casting, mold, die casting.

Die casting is a precision casting method that uses a high pressure to force a metal solution into a complex metal mold. Die casting is abbreviated as die casting, which is a casting method in which a molten alloy liquid is poured into a pressure chamber, a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting.

Casting dimensional accuracy is high, generally equivalent to 6~7, even up to 4;Good surface finish, generally equivalent to 5~8;

High strength and hardness, generally higher than sand casting by 25~30%, but extended the rate is reduced by about 70%;The size is stable and the interchangeability is good;The thin-walled complex casting can be die-cast. For example, the current zinc alloy die castings have a minimum wall thickness of 0.3 mm; aluminum alloy castings up to 0.5 mm; the minimum cast hole diameter is 0.7 mm, and the minimum pitch is 0.75 mm.

TIME PARAMETER OF DIE CASTING

Holding Time

After the molten metal fills the cavity, the casting is completely solidified under pressure. This period of time is called the holding time, and the holding time is related to the wall thickness of the casting and the metal crystallization temperature.

Retention Time

The time from the end of the holding pressure to the ejection of the casting from the mold opening is called the mold retention time. The mold retention time is determined according to the nature of the alloy, the wall thickness of the casting, and the structural characteristics. Generally, the minimum time for the casting to eject without deformation or cracking is appropriate.

TEMPERATURE OF DIE CASTING

Pouring Temperature

The average temperature of the molten metal poured into the injection chamber to the filling cavity, also known as the molten metal temperature, is usually at the lowest possible temperature, generally higher than the die-casting alloy, while ensuring the filling and quality requirements. The liquidus temperature is preferably 10~20 °C.

Die Casting Mold Temperature

The die-casting mold should be preheated before production, and a certain temperature should be maintained during the die-casting process. The die-casting mold is always in a hot state, which provides a basic guarantee for the filling and solidification of the alloy liquid. The zinc alloy is generally 150~200 °C; the preheating of the die casting mold can avoid the rapid cooling of the molten metal and reduce the fatigue stress of the die casting mold.

Looking for die casting servicesand high pressure die casting china, die casting in automotive industryproviders? EMP Tech must be your first choice.

EMP Techhave been serving the top brands like Mercedes Benz, Continental, Huawei from the begining of our foundation.IATF 16949(VDA6.3) certified factory, 15% of total staff are QC members who monitor the entire manufacturing process.

Send product request

Other supplier products

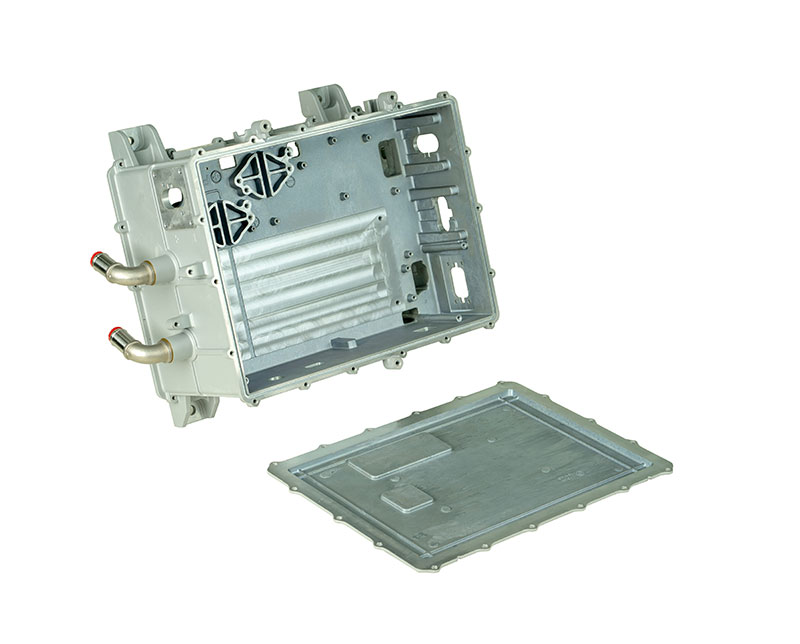

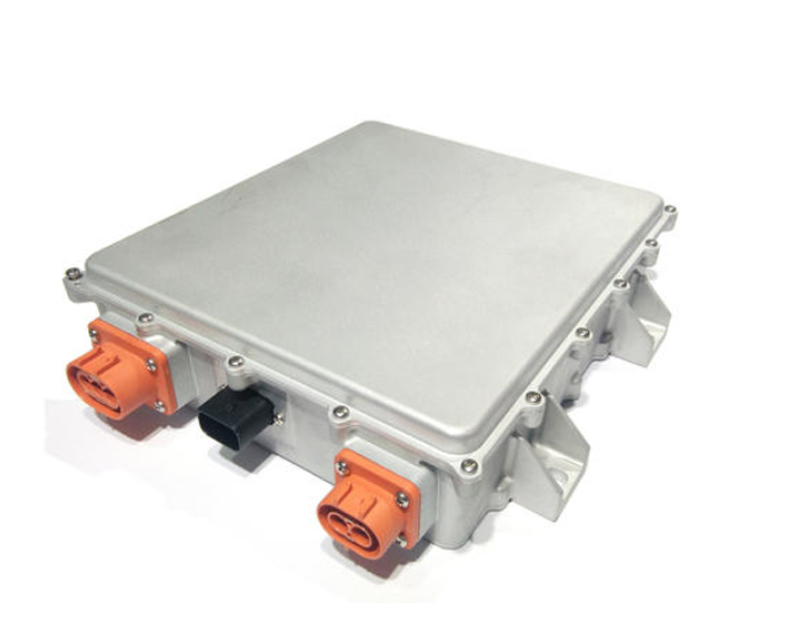

| ELECTRIC VEHICLE CONTROLLER HOUSING(PDU HOUSING) | Overview of electric motor and controller The electric car controlleris used to drive the main motor on the electric vehicle. Generally, it receiv... | |

| ELECTRIC VEHICLE AC-DC/DC-DC CONVERTERS (HOUSING) | Product Details of Electric Vehicle ac dc converter parts/DC-DC Converters (Housing): Specification: Custom-made Service: OEM/ODM Service Ma... | |

| ALUMINUM DIE CASTING VALVE PARTS | Aluminum Die Valve CastingParts Product Details: As one of die cast aluminum suppliers, we have types of related products for sale... | |

| TELECOM PARTS | EMP Techis one of theglobal, full-service aluminium die casting manufacturers in china. With more than 20 years' experience in research & devel... | |

| TELECOM PARTS | EMP Techis a global, full-service aluminum die casting manufacturer china. With more than 20 years' experience in research & development, manuf... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |