DIE CASTING

Die casting can be divided into: casting, mold, die casting.

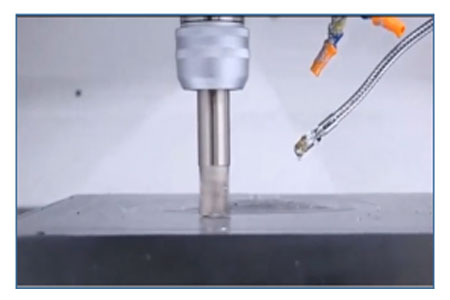

Die casting is a precision casting method that uses a high pressure to force a metal solution into a complex metal mold. Die casting is abbreviated as die casting, which is a casting method in which a molten alloy liquid is poured into a pressure chamber, a cavity of a steel mold is filled at a high speed, and the alloy liquid is solidified under pressure to form a casting.

Casting dimensional accuracy is high, generally equivalent to 6~7, even up to 4;Good surface finish, generally equivalent to 5~8;

High strength and hardness, generally higher than sand casting by 25~30%, but extended the rate is reduced by about 70%;The size is stable and the interchangeability is good;The thin-walled complex casting can be die-cast. For example, the current zinc alloy die castings have a minimum wall thickness of 0.3 mm; aluminum alloy castings up to 0.5 mm; the minimum cast hole diameter is 0.7 mm, and the minimum pitch is 0.75 mm.

TIME PARAMETER OF DIE CASTING

Holding Time

After the molten metal fills the cavity, the casting is completely solidified under pressure. This period of time is called the holding time, and the holding time is related to the wall thickness of the casting and the metal crystallization temperature.

Retention Time

The time from the end of the holding pressure to the ejection of the casting from the mold opening is called the mold retention time. The mold retention time is determined according to the nature of the alloy, the wall thickness of the casting, and the structural characteristics. Generally, the minimum time for the casting to eject without deformation or cracking is appropriate.

TEMPERATURE OF DIE CASTING

Pouring Temperature

The average temperature of the molten metal poured into the injection chamber to the filling cavity, also known as the molten metal temperature, is usually at the lowest possible temperature, generally higher than the die-casting alloy, while ensuring the filling and quality requirements. The liquidus temperature is preferably 10~20 °C.

Die Casting Mold Temperature

The die-casting mold should be preheated before production, and a certain temperature should be maintained during the die-casting process. The die-casting mold is always in a hot state, which provides a basic guarantee for the filling and solidification of the alloy liquid. The zinc alloy is generally 150~200 °C; the preheating of the die casting mold can avoid the rapid cooling of the molten metal and reduce the fatigue stress of the die casting mold.

Looking for die casting servicesand high pressure die casting china, die casting in automotive industryproviders? EMP Tech must be your first choice.

EMP Techhave been serving the top brands like Mercedes Benz, Continental, Huawei from the begining of our foundation.IATF 16949(VDA6.3) certified factory, 15% of total staff are QC members who monitor the entire manufacturing process.

在线联系供应商

Other supplier products

| TELECOM PARTS | Telecom Cover Parts Overview Vehicle telecommunication is often developed as part of the Intelligent Transportation System (ITS). Vehicle telecommu... | |

| GAS CAR PARTS | Aluminum die castings can be used in wiper systems, engine systems, filter systems, air conditioning systems, precision compressor parts, shock abs... | |

| MARKET PATTERN OF ALUMINUM ALLOY DIE CASTING IN CHINA | The global die casting manufacturing center is transferred to the mainland of China. China's precision die casting enterprises are mainly distribut... | |

| DIE CASTING PART | Aluminum die casting part can be used in wiper systems, engine systems, filter systems, air conditioning systems, precision compressor parts, shock... | |

| DIE CAST TOOLING | The tooling room is also the process equipment room, and various tools used in the manufacturing process, such as tools, fixtures, molds, measuring... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |