Compressors & Gears

Rayforce's metal cast iron gearscan be applied to Turbo blowers, air control component, piston compressors, casting gears, etc.

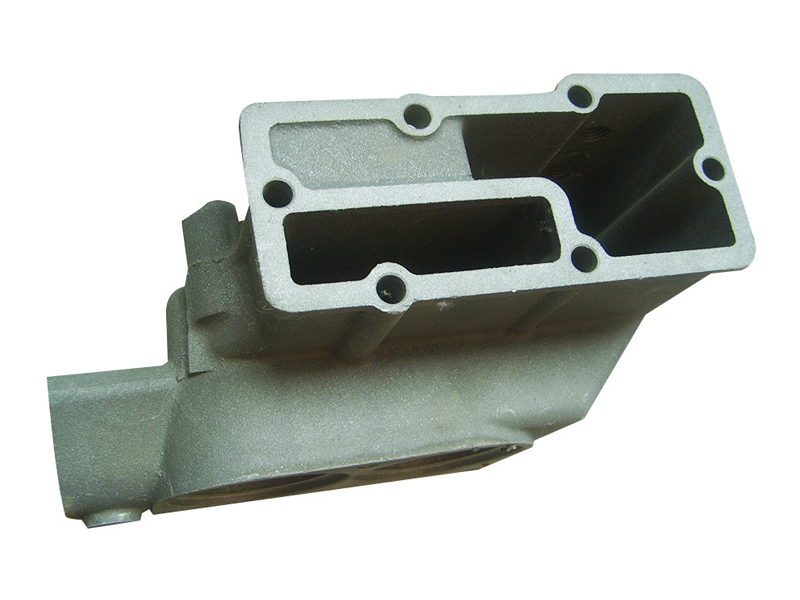

Application of Casting Gears in Air Compressors

With the continuous development of the automotive industry, the efficient high precision die casting production process is widely used in the production of automotive parts. Among them, the air conditioning compressor shell is a class of commonly used casting gears. This kind of shell product design a compact structure, high requirements for sealing. The whole machine's annual leakage requirements are strict. Once a large refrigerant leakage will affect the cooling effect of automotive air conditioning, which will seriously lead to air conditioning not cooling. For the lower shell, airtight inspection requirements generally to pressure of about 3MPa, holding pressure time of about 2min conditions shall not leak. To achieve these leak detection conditions, slight fluctuations in the quality of the casting, it is easy to cause bulk leakage, which will seriously affect the host plant production schedule on schedule.

Requirement of Casting Gears in Air Compressors

The lower casing is an important part of automobile air conditioner compressor, which has high requirements on its performance. The influence of casting gears shape structure and mold scheme design makes the casting easy to produce casting defects, which leads to the leakage of the product to become scrap after machine addition and seriously affects the subsequent assembly work beat and progress.

The analysis result of the die casting system composed of mold and die casting machine, after the improvement of die casting mold pouring system, the filling speed of the mold is reduced down, while the filling time is shortened significantly, no sticky mold occurs again at the gate. The casting gearsare effectively shrunken. The spraying time is also reduced to the normal level. The passing rate of the product in actual production is increased from 70% to more than 97%, thus significantly reducing the product cost. Besides, this has greatly reduced the product cost, prolonged the service life of the mold, enhanced the market competitiveness of the product, and brought good economic benefits to the enterprise.

Rayforce Manufacture is a private metal casting supplier, we provide metal casting china, vacuum die casting, casting small object bronzeand etc. Want to know more? Please contact us.

Send product request

Other supplier products

| Die casting | Die Casting involves 3 key elements: the die casting machine, the mold, and the alloy materials, and the die casting could be described as the proc... | |

| Metal Casting | Casting process usually refers to the metal casting process, is one of heating processing technologies handled by humans can be found recorded as e... | |

| Grey Cast Iron Casting | The name grey iron is because of the gray color of the fracture it forms, which is due to the presence of graphite. Grey iron die castingis the mos... | |

| Brass, Bronze, Copper Casting | As defined by its main properties, copper offers excellent electrical and heat conductivity, and good corrosion resistance ability as well. But nat... | |

| Application | Metal casting applications Marine Rayforce's metal casting can be applied to anchor, stern frames, anchor winch part, container corner castin... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |