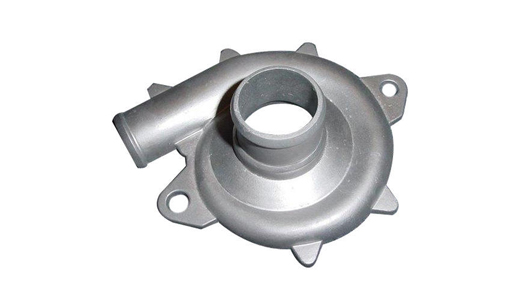

Grey Cast Iron Casting

The name grey iron is because of the gray color of the fracture it forms, which is due to the presence of graphite. Grey iron die castingis the most common and widely used casting material.

Grey iron is so popular in engineering applications because of its relatively low cost and the properties it presented. The grey iron has good galling and wears resistance because the graphite flakes self lubricates, and it also gives the gray iron part an excellent damping capacity because it absorbs the energy and converts it into heat.

Grey iron is very suitable for casting works. But during the casting process, a less solidification shrinkage than other casting iron shall be considered. The silicon promotes good corrosion resistance and increased fluidity when casting.

Below is a reference chart of other ASTM standards affecting grey iron.

ASTM A395 & ASME SA395: ferritic ductile iron pressure-retaining castings for

use at elevated temperatures

ASTM A439: austenitic ductile iron castings

ASTM A476 & ASME SA476: ductile iron castings for paper mill dryer rolls

ASTM A536 & SAE J434: ductile iron castings

ASTM A571 & ASME SA571: austenitic ductile iron castings for pressure-containing parts suitable for low-temperature service

ASTM A874: ferritic ductile iron castings suitable for low-temperature service

ASTM A897: austempered ductile iron castings

Ductile iron

Description of Gray Cast Iron

Gray cast iron is a type of cast iron. Carbon is present in cast iron in the form of flake graphite. The fracture is gray in color. It has good casting and cutting properties and good wear resistance. Gray cast iron is used in the manufacture of frames, boxes, etc. The graphite of gray cast iron is in the form of flake. The effective bearing area is relatively small, and the graphite tip is easy to produce stress concentration, so the strength, plasticity, and toughness of gray cast iron are lower than other cast iron. However, it has excellent vibration damping, low notch sensitivity, and high wear resistance.

Introduction to Cast Iron Molding

Cast iron moldings are broadly defined as objects cast in iron, which is the most commonly used metal.

Numerical simulation of the solidification process of thick and large section ductile iron castings with the application of computer was carried out for the temperature field. Increasing the strength of the mold shell, baking temperature and decreasing the pouring temperature are beneficial to reduce the scrap rate of castings and improve the quality of ductile iron castings.

Factors Affecting the Performance of Gray Cast Iron

The influence of chemical composition

In production, the quality fraction of carbon and silicon is mainly controlled. If the mass fraction of carbon and silicon is too low, the cast iron is easy to appear white mouth organization, and the mechanical properties and casting performance are very low; if the mass fraction of carbon and silicon is too high, the graphite flakes are too much and coarse, and even the graphite floats on the surface of the iron, which reduces the performance and quality of the castings. Therefore, the carbon and silicon content of gray cast iron is generally controlled at 2% to 4% C; 1.0% to 2.0% Si; 0.5% to 1.4% Mn.

The effect of cooling rate

Under certain casting process conditions, the cooling rate of the casting has a great impact on the degree of graphitization. Castings of different wall thickness with the increase in wall thickness, the cooling rate slows down, and carbon atoms have sufficient diffusion time. It is conducive to the full graphitization process, room temperature organization is easy to form gray iron organization; but thin-walled parts in the cooling process, the cooling rate is too fast, easy to form a white mouth iron organization.

Rayforce Manufacture as one of the most professional iron casting companiesand metal casting companies, we provide metal casting china, cast iron and ductile iron, cast iron ductile ironand etc. Want to know iron casting price per kgor more? Please contact us.

Send product request

Other supplier products

| Agriculture & Vehicle | Rayforce's metal casting can be applied to plough, tractor part, soil cultivation, planting, harvesting, hay making, animal feeding machine, etc. ... | |

| Metal Casting | Casting process usually refers to the metal casting process, is one of heating processing technologies handled by humans can be found recorded as e... | |

| Vacuum Investment Casting | Vacuum investment castingis one of the precision investment casting methods. This special technic is mainly applying to producing the small but hig... | |

| Compressors & Gears | Rayforce's metal cast iron gearscan be applied to Turbo blowers, air control component, piston compressors, casting gears, etc. Application of C... | |

| Low Pressure Die Casting | The low pressure casting machineis to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting ... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |