CNC Machining ABS

For 14 years, Flourish Legend has become one of the professional precision abs precision machining llcof abs machining partsin China, no matter how high the accuracy and complexity of the product, we are able to provide an automated machining process, major, comprehensive project management, leading assembly line and logistics services . Our mission has always been to assist customers in manufacturing high-quality parts at competitive prices and fast lead times. ABS materials are widely used in auto parts, electronic product casings, home appliances, toys, etc. Find out now how you and your business can take advantage of our services.

Basic Knowledge of china abs precision machining

ABS materials are widely used but very important machined plastic parts. It is a kind of "tough, hard and rigid" material with easy-to-obtain raw materials, good comprehensive performance, low price and wide application. ABS plastics are widely used in machinery, electrical, textile, automobile, aircraft, ship and other manufacturing industries and chemical industry.

|

Performance |

Basic performance |

Parameters |

|

Material properties |

Exterior color |

yellow, black, transparent |

|

Odor |

odorless |

|

|

Deformation temperature |

93°C-119°C |

|

|

Hardness |

Rockwell 109.5 (ASTM D786) |

|

|

Tension coefficient |

38MPa |

|

|

Tensile strength |

2414MPa |

|

|

Elastic elongation |

4% (D-791) |

|

|

Flexibility coefficient |

62MPa |

|

|

Flexibility |

2318 MPa |

|

|

Flexible elongation |

152% |

|

|

Impact performance |

Ai type impact 96.4J/m (D-257) |

|

|

Material properties: ABS is a thermoplastic polymer structure material with high strength, good toughness and easy processing. |

General performance |

The relative density of ABS is about 1.06, and the water absorption rate is low. ABS has a good combination with other materials and is easy to surface printing, coating, and plating. |

|

Mechanical properties |

ABS has excellent mechanical properties, its impact strength is excellent, and can be used at extremely low temperatures: ABS has excellent wear resistance, good dimensional stability, and oil resistance, and can be used for bearings under medium load and speed. |

|

|

Thermal properties |

The heat distortion temperature of ABS is 93~118°C, and the product can be increased by about 10°C after annealing. ABS can still show a little toughness at -40°C and can be used in the temperature range of -40~101°C. |

|

|

Electrical properties |

ABS has good electrical insulation and is hardly affected by temperature, humidity and frequency, so it can be used in most environments. |

|

|

Environmental performance |

ABS is not affected by water, inorganic salts, alkalis and various acids, but it is soluble in ketones, aldehydes and chlorinated hydrocarbons, and it will cause stress cracking when it is corroded by glacial acetic acid and vegetable oil. The weather resistance of ABS is poor, and it is easy to degrade under the action of ultraviolet light; after half a year outdoors, the impact strength drops by half. |

|

|

Precautions for ABS CNC Machining |

Clear processing content |

Determine the processing content of thecustomized CNC machiningcenter, determine the installation base surface, processing base surface, machining allowance, etc., and arrange the processing technology for the purpose of giving full play to the efficiency of the CNC machining center. |

|

Multiple clamping |

For complex parts, due to various reasons such as thermal deformation during processing, internal stress after quenching, and deformation of parts after clamping, it is difficult to complete the entire process after one clamping. At this time, two or more clamping can be considered. |

|

|

Arrange machining allowance |

When arranging the processing program, the principle of gradually refining from coarse to fine should be followed. Arrange heavy cutting and rough machining first, remove the machining allowance on the blank, and then arrange the content with low machining accuracy requirements. |

|

|

Large flow cooling method |

Adopt large flow cooling method. In order to reduce the influence of a large amount of heat generated during the machining process on the machining accuracy and improve the durability of the tool, a large flow cooling method should be used. |

|

|

Application Scenarios The largest application fields of ABS are automobiles, electronic appliances, and mechanical manufacturing fields. |

Automotive field |

Car dashboards, body panels, interior trim panels, steering wheels, sound insulation panels, door locks, bumpers, ventilation ducts, and many other components. |

|

Electrical field |

Widely used in refrigerators, televisions, washing machines, air conditioners, computers, copiers and other electronic appliances. |

|

|

Electronic product |

Notebook/desktop computers, copiers, printers, plotters, monitors. Electronic product casings, electric meter covers and housings, household switches, plugs and sockets, cable and wire conduits. |

|

|

Communication device |

Telecommunications, mobile casings, accessories and smart cards (SIM cards) |

|

|

Household appliances |

Washing machine, hair dryer, inner and outer parts of microwave oven, etc. |

|

|

Flourish Legend Machining Capabilities |

Serve |

25-hour dedicated account manager free follow-up |

|

Delivery speed |

5-10 days for general products, 15-31 days for mass products |

|

|

Wall thickness |

||

|

Tolerance |

±0.01 mm (approximately plus or minus 0.006 inches) |

|

|

Maximum part size |

200X80X01 cm |

|

|

Price |

Custom products from $2 |

Custom CNC Machining ABS Parts

ABS (acrylonitrile-butadiene-styrene copolymer) plastic is a commonly used engineering plastic with good impact resistance, wear resistance and rigidity, and is widely used in various fields. Here are some common products that are suitable for manufacture using ABS plastic:

Advantages of Using CNC To Process ABS Materials

Accuracy and Repeatability

Accuracy and Repeatability: CNC machining provides a highly accurate machining process, enabling precise cutting, milling, drilling and other operations on ABS materials. With pre-programmed instructions, the CNC machine can precisely control the movement and position of the tool, ensuring that the final part size and geometry are consistent with the design requirements. This precision and repeatability results in consistent quality and geometric characteristics for each machined part.

Complexity and Versatility

Complexity and Versatility: ABS material shows good machinability in CNC machining, and can realize the machining of complex shapes and structures. The CNC machine tool has multi-axis control capability, which can move and rotate the tool in multiple directions at the same time, so as to realize multi-axis cutting and processing of ABS materials. This makes it easier to manufacture complex parts while reducing process changeover and equipment occupancy time.

Automation And Production Efficiency

Automation And Production Efficiency: CNC machining is an automated processing process, which can greatly improve production efficiency by controlling the operation of machine tools through pre-written programs. The operator only needs to set up the machine tool and monitor the machining process, and the CNC machine tool will automatically perform precise machining operations, reducing human error and operating time, and improving production efficiency.

Flexibility and Quick Adjustment

Flexibility and Quick Adjustment: CNC machining is characterized by high flexibility and can be quickly changed and adjusted according to requirements. By modifying the CNC program, it can quickly adapt to design changes or changes in production requirements, reducing production cycles and costs. This flexibility enables manufacturers to quickly respond to market demands and flexibly adjust production plans.

We provide rapid prototyping manufacturing, cnc milling abs plastic, abs milling, cnc abs plastic, abs plastic extrusion, abs precision machining, etc. For more information, please feel free to contact us!

Send product request

Other supplier products

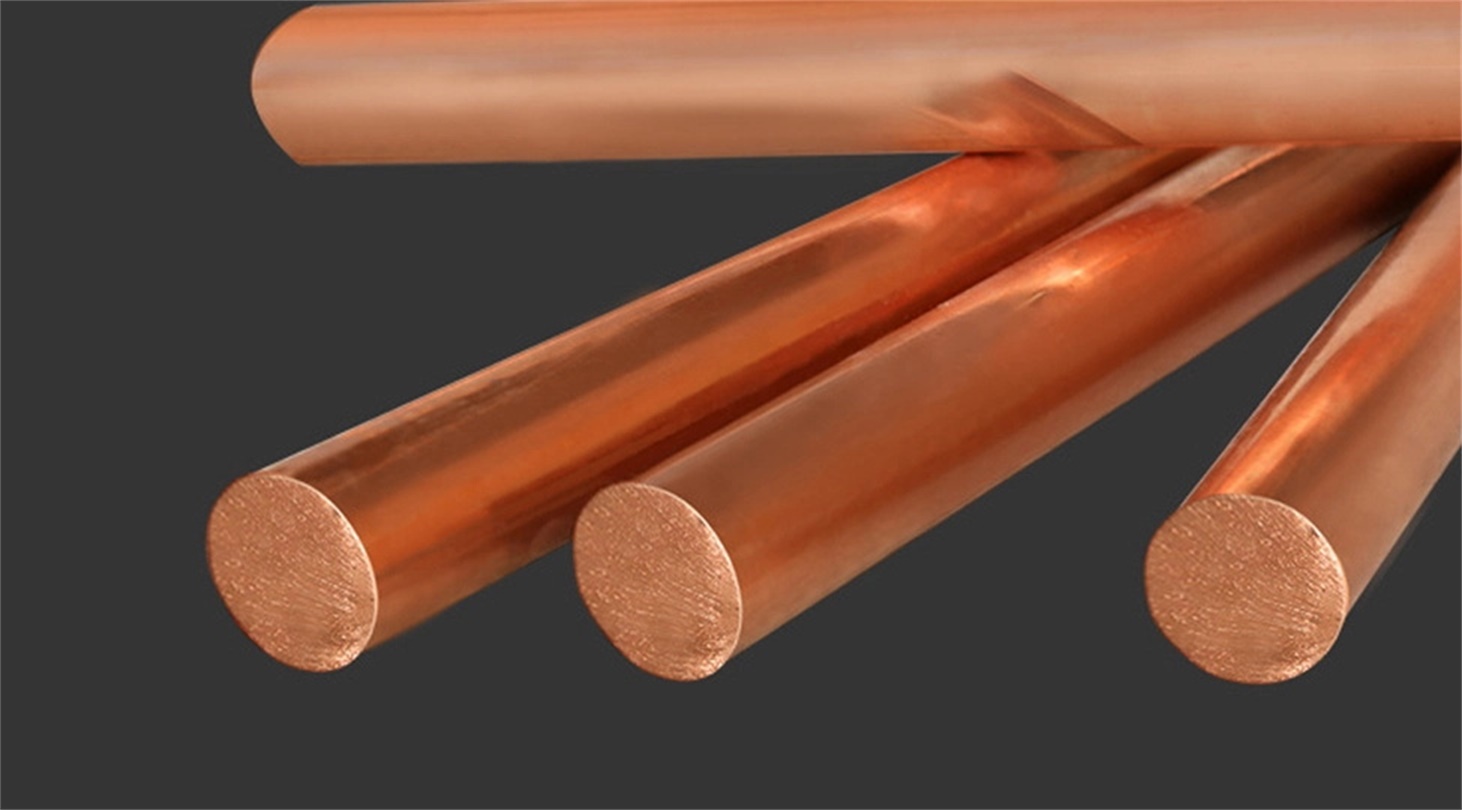

| CNC Machining Copper | Flourish Legend showcases the outstanding advantages of copper machining! Supported by advanced equipment and professional technical talents, we pr... | |

| CNC Machined and Molded Robotic Components Manufacturer | High Production Efficiency Superior Quality Automated Equipment Precision Machining Low Cost Flourish Legend's application in the field of r... | |

| CNC Machining Titanium | As a renowned manufacturing factory in China, Flourish Legend takes pride in its advanced equipment and professional technical talent. Our physical... | |

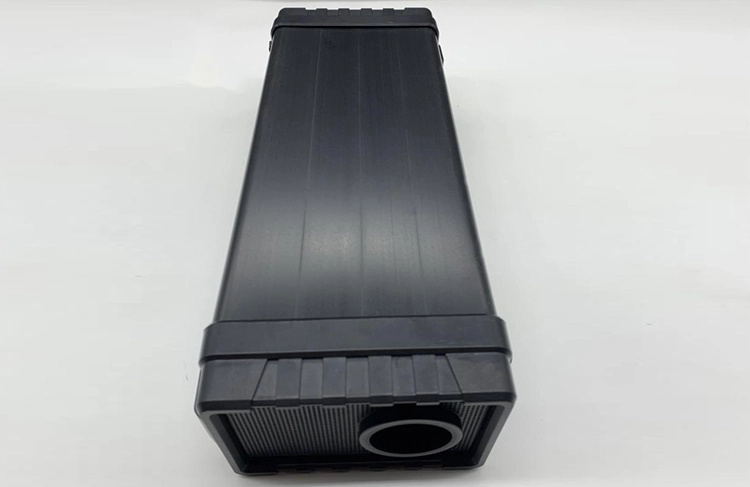

| Plastic Multifunctional Audio Enclosure | Customized multi-functional plastic audio shell, anti-flame retardant, waterproof plastic extrusion profile has the function of adding additives in... | |

| CNC Machining Stainless Steel | Flourish Legend, your one-stop solution provider for stainless steel component custom CNC machining! We take pride in our years of manufacturing ex... |

Same products

| MTL5582B MTL Intrinsically Safe Isolator 5500 Series RTD-RTD Isolator | Seller: 840499 | MTL 5500 Intrinsically Safe Isolators Resistance Isolator MTL5582B MTL4582B - MTL5582B RESISTANC... | |

| CNC Machining Services | Seller: Shenzhen Flourish Legend Limited | Flourish Legend is a high precision machining manufacturercertified with ISO 9001:2015. With an e... | |

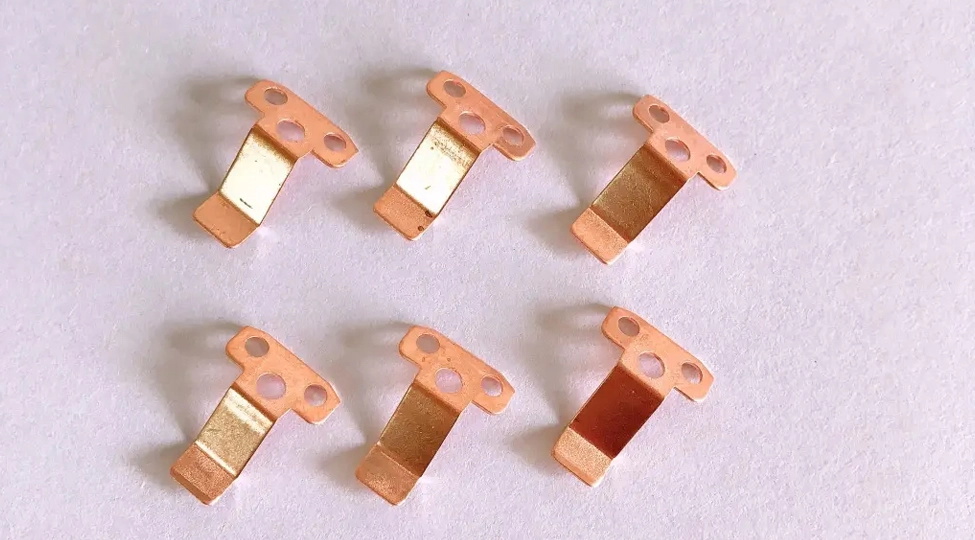

| Copper Stamping | Seller: Shenzhen Flourish Legend Limited | Flourish Legend Precision Hardware Copper Stamping - We have been specializing in production and ... | |

| CNC Turning | Seller: Shenzhen Flourish Legend Limited | Flourish Legend is equipped with cnc turning center manufacturerswith decades of experience. We s... | |

| CNC Machined and Molded Robotic Components Manufacturer | Seller: Shenzhen Flourish Legend Limited | High Production Efficiency Superior Quality Automated Equipment Precision Machining Low Cost ... |