CNC Machined and Molded Robotic Components Manufacturer

High Production Efficiency

Superior Quality

Automated Equipment

Precision Machining

Low Cost

Flourish Legend's application in the field of robotics covers various areas, including intelligent robots in the manufacturing, medical, education, service, and agriculture industries for customized CNC machining processing of robot components. We continuously innovate to promote custom manufacturing of robot components, bringing greater convenience and innovation to our clients.

What Are the Common Materials for Robotic Components?

In the robotics industry, common materials for robot components include but are not limited to the following:

The selection of these materials depends on the specific purpose and requirements of the robot, as well as cost and performance considerations. Different material combinations can meet various robot functionalities and performance requirements.

What Are the Considerations for CNC Machining Robot Components?

CNC prototyping machining of robot components requires the following considerations: Firstly, material selection should match the function and requirements of the robot components to ensure quality and stable supply. Secondly, precise accuracy requirements for the components should be clear to ensure high precision and quality control during the machining process.

Furthermore, designs should be reasonable to ensure perfect integration of the robot components with the system. Adequate maintenance and care of the machinery and tools during the machining process are essential to ensure stability and longevity. Finally, rigorous quality inspection and testing are necessary to ensure that the robot components meet performance standards and safety requirements.

Why Is Rapid Prototyping Widely Used in the Robotics Industry?

Rapid prototyping is widely used in the robotics industry because it offers a fast and cost-effective prototyping solution. Robot design and development involve multiple iterations and testing. Rapid prototyping allows engineers and designers to quickly validate design concepts, aiding in the rapid detection of issues and improvements. Moreover, rapid prototyping offers versatility in material usage, suitable for manufacturing various robot components such as structural parts, casings, and sensor brackets. Through rapid prototyping, the product development cycle can be accelerated, reducing development costs, thereby driving continuous innovation and application of robotics technology.

What Are the Core Components of A Robot, and What Is the Typical Manufacturing Process?

The core components of a robot include motors, sensors, controllers, actuators, and power supply. Motors drive the robot's movement, sensors perceive the environment and collect data, controllers process and execute commands, actuators perform the robot's actions, and the power supply provides energy for the robot.

The general manufacturing process for robots includes design, model production, CNC machining, assembly, and testing. The design phase establishes the robot's structure and functionality, model production employs techniques like hand board models or 3D printing for rapid prototyping, CNC machining is used to manufacture high-precision components, assembly integrates all parts into the robot, and finally, rigorous testing and debugging ensure the robot's performance and stability."

As a robot prototype maker, We provide rapid prototyping service, robotic welding parts, robot prototype design, cnc manufacturing robotics, military robot prototype, verb surgical robot prototype, prototyping robotics industry, prototype of robot, etc. For more information, please feel free to contact us!

Send product request

Other supplier products

| Look For CNC Machining Metal Materials | As an advanced cnc metal machining factoryin Guangdong, China, Flourish Legend is committed to providing high-quality and precision custom parts an... | |

| CNC Milling | What is cnc milling Flourish Legend is a cnc milling service supplierwith decades of experience in metal and plastic milling. We specialize in CNC... | |

| Rectangular Stainless Steel Watch Case | Flourish Legend specializes in customized stainless steel watch case manufacturing, offering professional customization of various mechanical, qu... | |

| Stainless Steel Bolt | Advantages of customized stainless steel bolt products: through precise custom processing, stainless steel cnc body boltshave strong corrosion re... | |

| CNC Machining Titanium | As a renowned manufacturing factory in China, Flourish Legend takes pride in its advanced equipment and professional technical talent. Our physical... |

Same products

| MTL5582B MTL Intrinsically Safe Isolator 5500 Series RTD-RTD Isolator | Seller: 840499 | MTL 5500 Intrinsically Safe Isolators Resistance Isolator MTL5582B MTL4582B - MTL5582B RESISTANC... | |

| CNC Machining Services | Seller: Shenzhen Flourish Legend Limited | Flourish Legend is a high precision machining manufacturercertified with ISO 9001:2015. With an e... | |

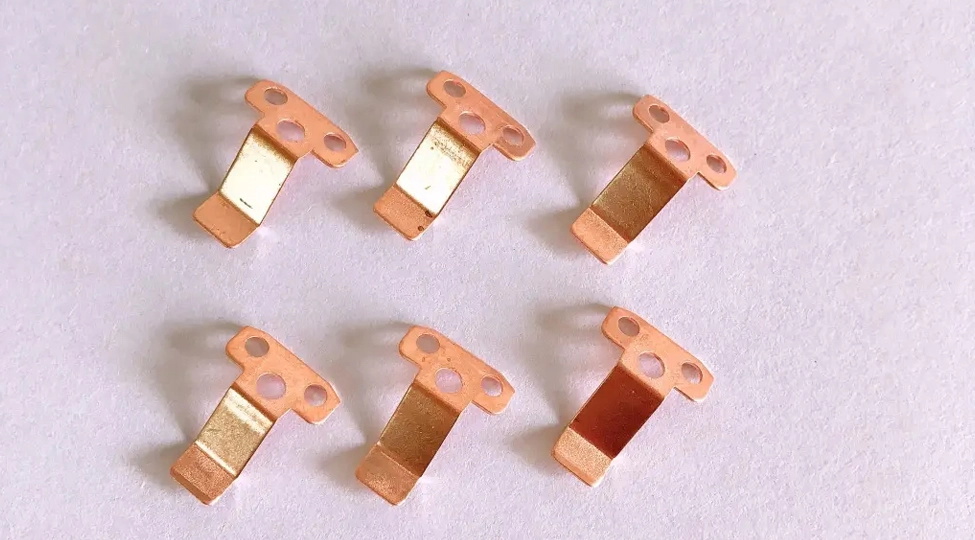

| Copper Stamping | Seller: Shenzhen Flourish Legend Limited | Flourish Legend Precision Hardware Copper Stamping - We have been specializing in production and ... | |

| CNC Turning | Seller: Shenzhen Flourish Legend Limited | Flourish Legend is equipped with cnc turning center manufacturerswith decades of experience. We s... | |

| CNC Machined and Molded Robotic Components Manufacturer | Seller: Shenzhen Flourish Legend Limited | High Production Efficiency Superior Quality Automated Equipment Precision Machining Low Cost ... |