MOC-K100 Mould Online Oscillation Monitoring System

MOC-K100Mould Online Oscillation Monitoring System

Overview

Mold is the castingbilletforming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plateto export its heatand to gradually solidify it into acasting billetwith the required cross-sectional shape andbilletshell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lowernozzleof the mold to create conditions forcasting billetto be completely solidified in the subsequent secondary cooling area.

The main function of themouldoscillationdevice is to make themouldperform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the castingbillet with the copper wall of the mold during the solidification process.

MOC-K100mouldonlineoscillationmonitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of themouldoscillation.Theonlinechangingdata is provided in real time,which providesconvenient and effective detection methods for on-site inspection personnel.

The meaning of the system

1. When thecontinuouscasting machine is not working properly, thebillet quality problems (such as unstableoscillationmarks, edge cracks, etc.)occur. According to the monitoring results of the system,we cancombine with the actualon- sitesituationtoanalyze the cause of the failure, and efficiently evaluate and solve the problem of theoscillationtabletoimprove product quality.

2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expectedoscillationparameters of the mold and the actualoscillationparameters will have aoscillationdifferencewith time change, resulting in the internal process parameters’changingof thecontinuouscasting machine.Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance.

3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear.Prevent over-repair and under-repair.

4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoidadoptinginaccurate or large-erroroscillationto work and prevent the "breakout" accident.

5.We can timelyfind out that theoscillationis not stable or out of control in a small range, so as to avoid the formation of unevenness and unstableoscillationmarks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product.

6. Adjust the working parameters reasonably according to the monitoring results, avoidingthe use of excessive safety factor, makingthe entire assembly line play a normal working efficiency, increasingthe output of billets, and create favorable conditions for increasing thecastingspeed.

The functionsof the system

(1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data includingoscillationparameters and process parameters.

(2) Time domain waveform: This function mainly displays theoscillationwaveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elementsof oscillationof each measuring point in real time.

(3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and theoscillationdifference of each channel can be calculated and displayed intuitively.

(4) FFT: This functional module completes the calculation and display of theoscillationspectrum in real time. It is used to evaluate the waveform distortion of the entireoscillationtable and to determine whether there is a problem with the installation of theoscillationdevice.

(5) Bar graph: Theoscillationof each measuring point is indicated by a bar graph of peak-to-peak value and sensor gap voltage, which is more intuitive.

(6) Trend:Afterstarting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings under differentoscillationconditions of different steels.

The parametersof the system

1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged

2. Sensor: three-dimensionaloscillationsensing (X, Y, Z three axes)

3. Sensitivity: 1000mV/g

4. Frequency range: 0.04~10HZ

5. Frequency accuracy: ±0.01 Hz

6. Amplitude accuracy: 0.005mm

7. Transmission mode: wired digital transmission; wireless transmission

8. Host: 3U standard rack; handheld device

9. Sensor power supply: 24V.DC

10. Host power supply: 220V.AC/50Hz

The structureof the system

The main components of the continuous casting mouldonline oscillationdetection system are:

1. Three-dimensionaloscillationmeasurement sensor

2. Handheldoscillationsensorcalibrator

3. Dedicated signal connection cable

4. Preamplifier

5. Operation processing unit

6. Graphic display terminal

7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components

8. Control cabinet

Send product request

Other supplier products

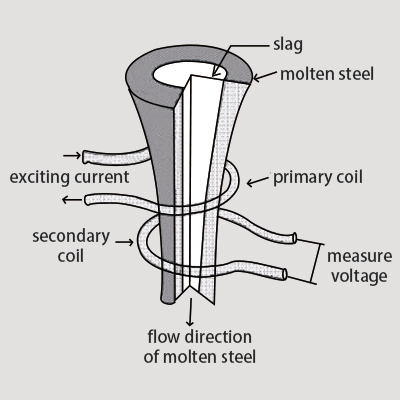

| LAG-S100 Ladle Slag Detection System (Eddy Current) | LAG-S100Ladle Slag Detection System (Eddy Current) Overview The continuous casting ladle slag detection device is used to detect the slag conte... | |

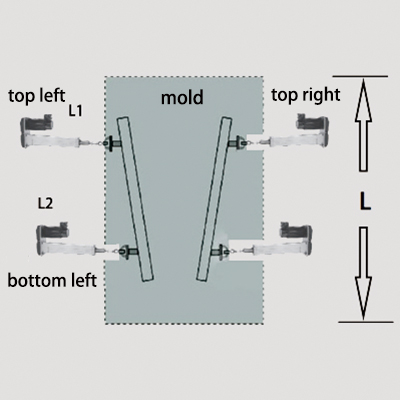

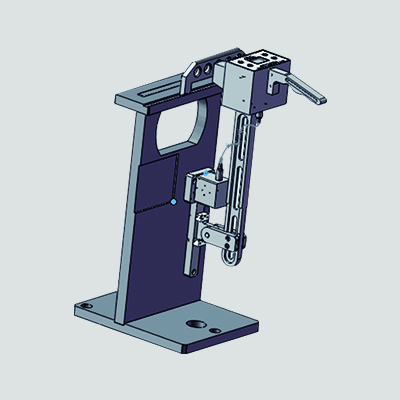

| Mould Online Width Adjustment and Taper Measurement | Mould Online Width Adjustment and Taper Measurement Overview In order to meet the needs of producing various specifications ofcontinuously cast... | |

| MDC-K120 Slab Mold Taper Measuring Instrument | MDC-K120Slab Mold Taper Measuring Instrument Overview The taper of the narrow face of the mold has an important influence on the quality of t... | |

| SPD-V020 Multifunctional Strand Condition Monitor | SPD-V020Multifunctional Strand Condition Monitor Overview In the production process of the multifunctionalstrandconditionmonitor, in order to e... | |

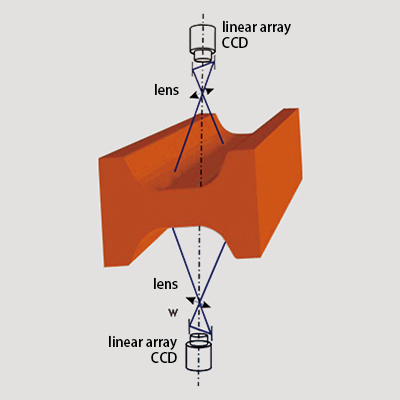

| ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) | ZSQ-T200 Online Surface Quality Inspection System for Continuously Cast Product (CCD) Overview The surface quality inspection of high temperatu... |

Same products

| Lifting Beams Adjustable Lifting Beam | Seller: Hebei Connect Trading Co.,Ltd | Structure: I Beam For Lifting type and streamline form. Working Load Limit: 2 Ton to 50 Ton A... | |

| Replacement of PALL HC8304FAN16H Hydraulic filter element | Seller: Xinxiang Saya Filters Co., Ltd | Product Advantages: 1. Using glass fiber from the American HV brand as the filter layer, the fil... | |

| Argo V2.1260-06 Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Performance characteristics of Argo V2.1260-06 Hydraulic Filter Replacement: 1. Good filtration p... | |

| Eaton Internormen Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Product Description: The filter elements have the characteristic on high pressure collapse resis... | |

| Sullair / Air Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Ayater air filter Introduction: ● Air Filter Element is a critical part of Compressor, made of hi... |