Mould Oscillation and Deflection Detection Instrument

Mould Oscillation and Deflection Detection Instrument

Overview

The mold is a device that shapes thecast productin continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of themouldoscillationdeflectiondetectioninstrument is to detect the themould oscillationtable’s oscillationfrequency, amplitude, deflection rate, phase,oscillationtrajectory curve, etc. Through the detection and adjustment of the detection instrument, the mold moves along the outer arc of the continuous casting machine according to the given amplitude, frequency and waveform deflection characteristics.

The actualoscillationparameters of the moldoscillationtable during the operation and production process and the process parameters of thecast productscannot be effectively knownwithout the data detection of the mold deflectiondetectioninstrument,so thatthe operatorcannot adjust the mould’s production process parameters in real time according to the real-time situation of the on-site production.

The continuous casting mold deflectiondetection instrumentindependentlydeveloped by our company is suitable for various molds such as slab, square billet, round billet andshaped billet. The system obtains theprocess parameters such asactualoscillationholographic parameters and negative slipamountof theoscillationtable by effectively detecting the movement of the mold. The technicians can formulate the control strategy of themouldaccording to these actual parameters, and improve the output and quality of the product within a safe and reliable range.

The structure of the instrument

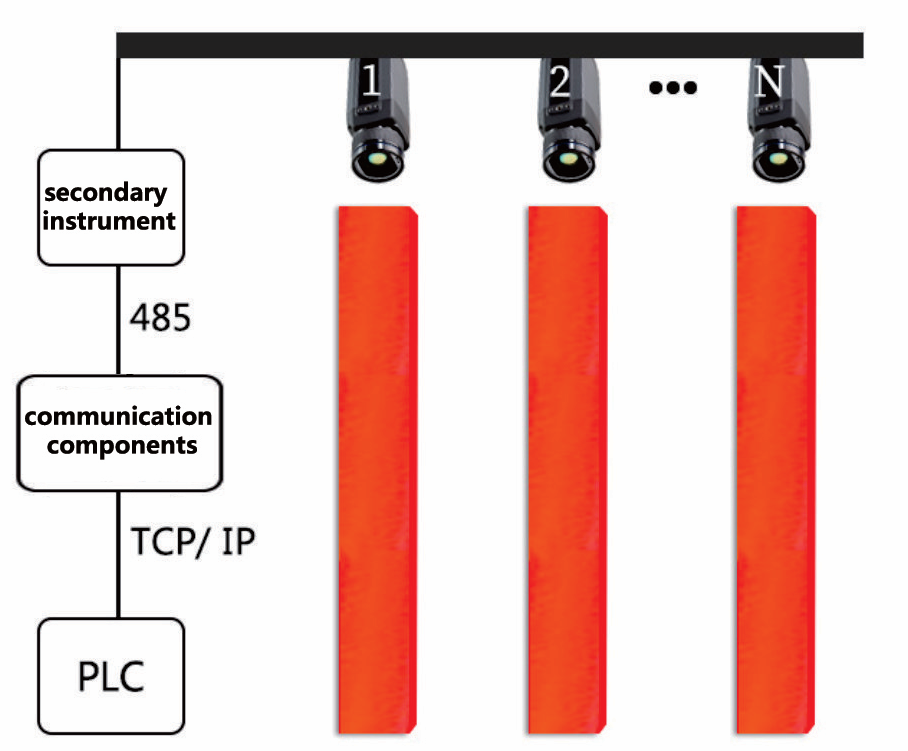

Continuous casting moldoscillationanddeflectiondetectioninstrument is mainly composed of sensor system, sensor signal conditioning circuit, power supply circuit, synchronous data acquisition module, communication cable, and software data analysis system.

There are three axial acceleration sensors installed in the moldoscillationand deflectiondetectioninstrument, one of which is to detect the verticaloscillationsignal (Y axis), and the other two are to detect the horizontaloscillationsignal (X and Z axis). The signal obtained by the sensor is processed by the preprocessor and the preprocessing module. The oscillation signal and sensor status signal will be filtered and normalized, sent to the synchronous data collector for digitization and feature extraction, and the data is analyzed and processedby themastercomputer software to obtain variousoscillationparameters and process parameters required by users.

The functions of the system

1. Adopting mould oscillationX/Y/Z three-dimensional data acquisition, using high-precision sensor system and high-sensitivity axial accelerometer, comprehensive detection of equipmentoscillationstate, including:

1) Detect theoscillationfrequency of the moldoscillationtable

2) Detect the amplitude of the moldoscillationtable

3) Detect the deflection rate ofoscillation

4) Detect the lateral deflection, longitudinal deflection, phase, and phase difference of the moldoscillationtable

5) Three-dimensional display of theoscillationtrajectory, and theoscillationtable trajectory can be viewed from all sides of theoscillationtable 6 (X-Y, X-Z, Z-Y)

2. The software system adopts the designofman-machine interactive graphic interface, which can display themold oscillationstate in real time. The software functions include:

1) Real-time data curve display:oscillationwaveform,oscillationfrequency, signal superposition analysis

2) Single-axis curve display, multi-axis curve display, amplitude, acceleration, three-dimensional graph

3) View historical curve

4) Generate test report

5) Give a warning prompt

6) Spectrum analysis function

7) Long-term storage of data

3. Portable measurement method, which can provide handheld detection equipment with wireless remote transmission, and the operation is simple.

4. Provide an overview of inspection parameters under the full screen, displaying all data includingoscillationparameters and process parameters. At the same time, the calculation and display of theoscillationspectrum is completed in real time, which is used to evaluate the waveform distortion of the entireoscillationtable, and to determine whether there is a problem with the installation of theoscillationdevice.

5. Alarm management. Record each alarm data under real-time alarm conditions to analyze the cause of the alarm and evaluate the impact of the alarm on production.

6. Parameter setting. Users can set the idealoscillationvalue and normal working range of various steels online. We also canset the alarm limit, and the storage time of the databaseetc.

7.After charging the deviceonce, itcan work continuously for more than four hours.

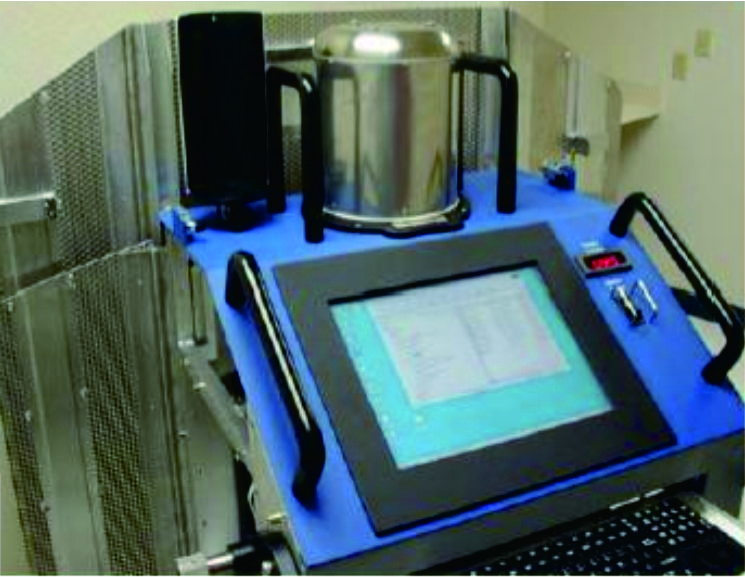

8. Integrate embedded processing equipment to realize data collection, display, analysis, reporting and other functions.

9. According to the mold characteristics and user requirements, it can be flexibly configured,wich issuitable for all types of molds such as square billets, slabs, round billets and other moldoscillation tables.

10. Support wired and wireless data transmission functions, easy to use.

11. Use thelaptopto receive the collected data,can beused forthe operation test on site, andcananalyze and process the data conveniently.

The features of the system

1. The actual oscillation state replaces the ideal oscillation state. The actual oscillation state of the table is used to formulate a control strategy, so that the oscillation table can be used to produce products with more accurate oscillation.

2. Convenient detection method. The equipment can be used for on-site inspection at any time, and the production site can grasp the operating status of the on-site equipment in time, so that we can make production adjustments to the equipment at any time.

3. Efficient working methods and processing platforms. The high-integration equipment developed by embedded technology can work in high temperature and harsh environment. This system can comprehensively detect XYZ three-axis data, and realize real-time data analysis and processing with high-speed data operation and processing platform.

4. Powerful database function. The database adopts the mode of computer automatic management and operator's manual assistance management, and there are tables for recording historical data and alarm data and working parameter setting table of monitoring system inside the database. By adjusting the output range, the best output effect can be obtained.

Send product request

Other supplier products

| MOC-K100 Mould Online Oscillation Monitoring System | MOC-K100Mould Online Oscillation Monitoring System Overview Mold is the castingbilletforming equipment in continuous steel casting, and it is a... | |

| On-line Billet End Continuous Temperature Measurement | ZST-P100 On-line Continuous Temperature Measurement of the Billet End Overview Thesystem aimsat the continuous temperaturedetectionof theproducto... | |

| SPD-V010 Handheld Roll Gap Checker | SPD-V010Handheld Roll Gap Checker Overview The handheld roll gapcheckeris specially used to measure the length between spherical surface, arc... | |

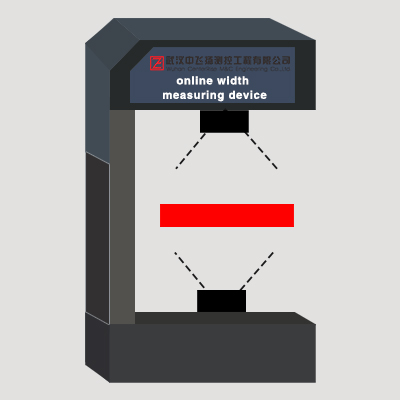

| WGS-L020 Flat Steel/Ribbon Iron Width Measuring System | WGS-L020Flat Steel/Ribbon Iron Width Measuring System Overview Whether the width and thickness of the flat steel/ribbon iron width measuremen... | |

| LDT-L200 Ladle Lining Laser Thickness Gauge | LDT-L200Ladle Lining Laser Thickness Gauge Overview LDT-L200 is a new generation ofladlelining thickness gauge launched by our company. The sys... |

Same products

| Lifting Beams Adjustable Lifting Beam | Seller: Hebei Connect Trading Co.,Ltd | Structure: I Beam For Lifting type and streamline form. Working Load Limit: 2 Ton to 50 Ton A... | |

| Replacement of PALL HC8304FAN16H Hydraulic filter element | Seller: Xinxiang Saya Filters Co., Ltd | Product Advantages: 1. Using glass fiber from the American HV brand as the filter layer, the fil... | |

| Argo V2.1260-06 Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Performance characteristics of Argo V2.1260-06 Hydraulic Filter Replacement: 1. Good filtration p... | |

| Eaton Internormen Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Product Description: The filter elements have the characteristic on high pressure collapse resis... | |

| Sullair / Air Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Ayater air filter Introduction: ● Air Filter Element is a critical part of Compressor, made of hi... |