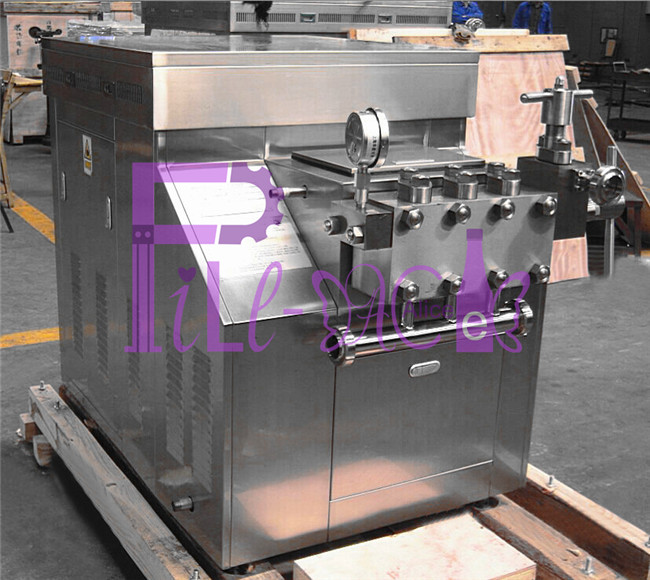

3000L/h 2 stage homogeniser for juice and dairy products

Title:3000L/h 2 stage homogeniser for juice and dairy products

Key words:homogenizer, homogeniser,FILL-PACK homogenization machine

Model:JJ-3-25

Brand:FILL-PACK

Power:22kw

Voltage:380V 3PH 50HZ or customized

Driven force type:Electrical

Automation degree:automatic

Application:juice homogenization

Condition:New

FILL-PACK homogenization machine

PROPERTIES:

Volume:3000L

Key material:SUS304

Fuction:juice homogenization

Stage:2

Working pressure:25Mpa

Motor power:22Kw

Inlet/outlet:25mm

Origin:ZhangJiaGang, China

After sales service:Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

Special ceramic material homogenizationvalve

the materials are composed of various pottery and porcelain, which suit for rubbing rigid products, cobalt chromium tungsten alloy and tungsten rigid is also optional.

W-type cobalt chromium tungsten alloy homogenization valve

prolonged rotating space of homogenization liquid can reduce energy consumption and produce high efficiency and homogenization efficiency. the two-stage w-type valve is widely used for processing of emulsification separate and suspended matter.

Waviness type special cobalt chromium tungsten alloy valve assembly

according to flux design needed ,it adopts waviness to make cobalt chromium tungsten alloy assembly ,adjusted the gap of homogeneous via moving valve cone and fixed valve seats, it appears radial throttle function between two kinds of fluid, and gets homogeneous fluid. the materials processed are fully homogenization and emulsified.

FILL-PACK homogenization machine

special material plunger

It adopts cobalt chromium tungsten alloy plunger of anti-corrosion and antifriction surface welding and surface coated ceramic plunger, the useful life of seal assembly and seal ring is prolonged.

Materials:

1, Main Frame, power supply box: cast iron;

2, Outer covering: 1cr17ni2;

3, Parts touching liquid:

A, pump chamber and inner turnbuckle: SUS 304

B, the parts except pump chamber and inner turnbuckle: 1cr17ni2 (for durability);

Parameters:

Working pressure:25MPa

Capacity:3000L/H

Power:22KW

Inlet:25mm

Outlet:15mm

Viscosity:≤0.2

Temperature:≤80℃

Motor speed:1440 rpm

Weight:1300kg

Overall dimension:1600*1100*1550mm

Send product request

Other supplier products

| FILL-PACK Can Filling Machine-1 | FILL-PACK Can Filling Machine-1 Title:Inclined tunnel type can washing machine for aluminum cans Key words:can washing machine, can rinsing machine... | |

| Reverse sterilizer for bottled juice filling line | Reverse sterilizer for bottled juice filling line QUICK DETAILS: Model:DP-8 Brand:FILL-PACK Power:0.75kw Voltage:380V 3PH 50HZ or customized Driven... | |

| Glass bottle ROPP cap carbonated beverage filler with bottle centering guide | FILL-PACK Carbonated Filling Machine Title:Glass bottle ROPP cap carbonated beverage filler with bottle centering guide Key words:carbonated b... | |

| 3000L/h 2 stage homogeniser for juice and dairy products | Title:3000L/h 2 stage homogeniser for juice and dairy products Key words:homogenizer, homogeniser,FILL-PACK homogenization machine Model:JJ-3-... | |

| FILL-PACK water filling machine for sale | FILL-PACK water filling machine for sale Title:Linear pheumatic water filler for 3-10L big water bottles Key words:water filler, water bottling mac... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | Seller: Hangzhou siseyin Technology Co., Ltd | ||

| Sticker equipment | Seller: Hangzhou siseyin Technology Co., Ltd | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |