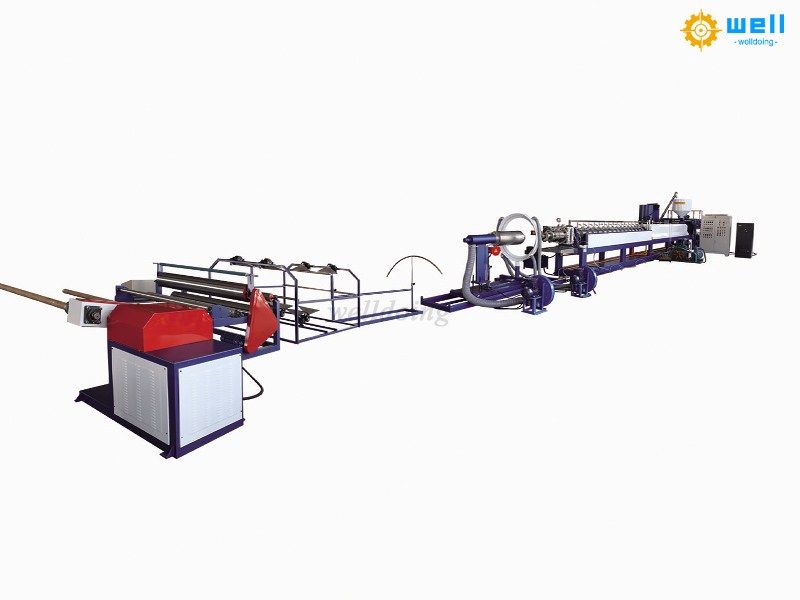

China EPE Foamed Tube making Machine

ChinaEPE foamed tube making machineitself cannot produce bubbles out of thin air. It introduces butane into the barrel, which is fully mixed and extruded by the screw. At a certain temperature, it realizes the contact surface between liquid and gas as large as possible to form bubbles.

There are many brands and types of foaming machines, but according to the foaming thickness, 75 machines, 90 machines, 105 machines, 120 machines, 135 machines, 150 machines, 170 machines, 180 machines and 200 machines are widely used at present. According to the shape of foamed products, foamed sheets, foamed pipes, foamed bars, foamed corner profiles (such as L-shape and U-shape), foamed round bars, foamed laths, etc. are currently applied, but there are differences in their auxiliary equipment and automatic control. The structure of the foamed part is the same.

The EPE foam tube production line produced by our factory has reasonable structure, scientific design, advanced configuration, energy saving and high efficiency; The production line has the advantages of convenient operation, automatic temperature control, safety and power saving, stable operation, stable and reliable product quality, and can continuously produce foamed sheets of various specifications.

WELLDOING TRADING Co. Ltd. is a manufacturer + sales and after-sales company, which is mainly engaged in large-scale semi-automatic chain-bar water-based printing machine,automatic flexo printer slotter die cutter stacker machine , high-speed high-definition paper box printing and slotting die-cutting machine, 2 layers corrugated production line, box-sticking machine, Tying Machine ,automatic partition assembler machine,,, EPE foam tube making machine and so on.

Our Services

1. OEM service are available.

2. Trade Manager online, also contact by Email.

3. To solve problems by pictures/videos.

4. Engineers are available service abroad.

FAQ

1. Are you a factory or trading company?

We are both a factory and a trading company in this field .

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,

pay the 70% balance before delivery, but we can also accept the L/C.

3. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling fromthe very small thing(even a small screw we will choose the best quality) from thebeginning

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Send product request

Other supplier products

| Paper edge protector machine paper V corner board making machinery | paper V corner board making machineryintroduction: 1. The processing technology of the ball screw is fine, the clearance between the screw and the... | |

| paper angle edge corner cardboard protector making machine | Product Description 1)Paper Angle Board Machine is a kind of machine that specializes in the production of paper corner. It is generally composed ... | |

| Automatic drink carton corrugated paper box folder gluer machine | Automatic drink carton corrugated paper box folder gluer machine consist of three sections: vacuum feeding section, gluing and folding section, cou... | |

| corrugated cardboard flexo printing die cutting slotting machine | Purpose and characteristics: The machine can complete multi-color printing, die cutting, wire pressing and slotting. On the basis of similar produ... | |

| corrugated carton 1-4 color printer die cutter slotter machine | Paper feeding section (one group) 1. Machine clutch: 1) An alarm bell is attached to the clutch of the electric control machine, and the alarm be... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | Seller: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | Seller: Hangzhou siseyin Technology Co., Ltd | ||

| Sticker equipment | Seller: Hangzhou siseyin Technology Co., Ltd | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |