Direct Reduced Iron (DRI Steel)

Description of Direct Reduced Iron (DRI Steel)

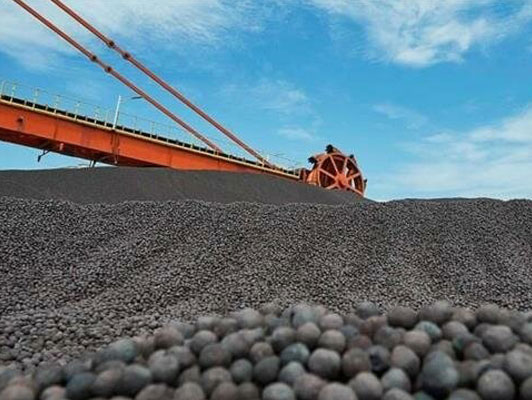

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore(in the form of lumps, pellets, or fines) to iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suitable for making direct reduction iron.

Direct reduction refers to solid-state processes that reduce iron oxides to metallic iron at temperatures below the melting point of iron. Reduced iron derives its name from these processes, one example being heating iron ore in a furnace at a high temperature of 800 to 1,200 °C in the presence of the reducing gas syngas, a mixture of hydrogen and carbon monoxide.DRI is produced through the removal (reduction) of oxygen from iron ore in its solid state. This technology encompasses various processes based on different feedstocks, reactors, and reducing agents. DRI processes can reduce CO2 emissions by using natural gas instead of coal due to the replacement of carbon reductant by hydrogen from the methane.

Basic characteristics of Direct reduced iron (DRI)

Direct Reduced Iron Process

Indirect reduction plant, the oxide pellets produces in the pelletizing plant enters the reduction plant from the top into the furnace after it has had its chemical and physical properties checked, and loses its oxygen to the reducing gas which flows upwards from the bottom of the module.H2 and CO and H2O is the initial mixture of the reducing gas with the radio of 1.5 to 1.7. This mixture absorbs the oxygen content of the pellets and changes into CO2 and H2O and gets out of the furnace from the top.

Our company is a direct reduction iron company,we provide cold rolled sheet,cold rolled steel plateand direct reduced iron process,we are you best choice.

Send product request

Other supplier products

| Anode Carbon Block | Anode Carbon Block Overview It participates in electrochemical reactions and directs current into the electrolytic cell. Each prebaked carbon anode... | |

| Cold Rolled Steel Strip | Description of Cold Rolled Steel Strip Strip steel has more stringent thickness tolerances than cold-rolled steel. Before rolling, cold rolled stee... | |

| Cold Rolled Coil | Description of Cold Rolled Coil Cold rolled coil, as known as CRS or CRC. Cold rolled steel coils are a farther product that uses hot rolled steel ... | |

| STEEL PRODUCTS AND RAW MATERIALS FOR STEEL INDUSTRY | Steel Product Different types of raw steel productsare necessary for a host of different industries. And they are important commodities related to... | |

| STEEL PRODUCTS AND RAW MATERIALS FOR STEEL INDUSTRY | Steel Product Different types of raw steel productsare necessary for a host of different industries. And they are important commodities related to... |

Same products

| Sapphire optical window | Seller: He Rui Optics Co., Ltd | Materialoptical glass,BK7 ,Fused silica, Ge,Si,CaF2,ZnSe,ZnS,BaF2,MgF2,LiF,KBr,Nacl,Corning Eagle... | |

| Micro glass beads making plant | Seller: QINHUANGDAO YOUSEN IMPORT&EXPORT TRADING LTD | ||

| Hot Rolled Steel Plate | Seller: Huaruo (Shanghai) Industrial Co., Ltd. | Main Feature of Hot Rolled Steel Plate Hot steel coils production is a rolling procedure that rel... | |

| Hot Rolled Steel Coil | Seller: Huaruo (Shanghai) Industrial Co., Ltd. | Description of Hot Rolled Steel Coil Hot rolling is a mill process that involves rolling the stee... | |

| Hot Briquetted Iron (HBI Iron) | Seller: Huaruo (Shanghai) Industrial Co., Ltd. | Definition of HBI Hot Briquetted Iron (HBI) is a premium form of Direct Reduced Iron (DRI).As a s... |