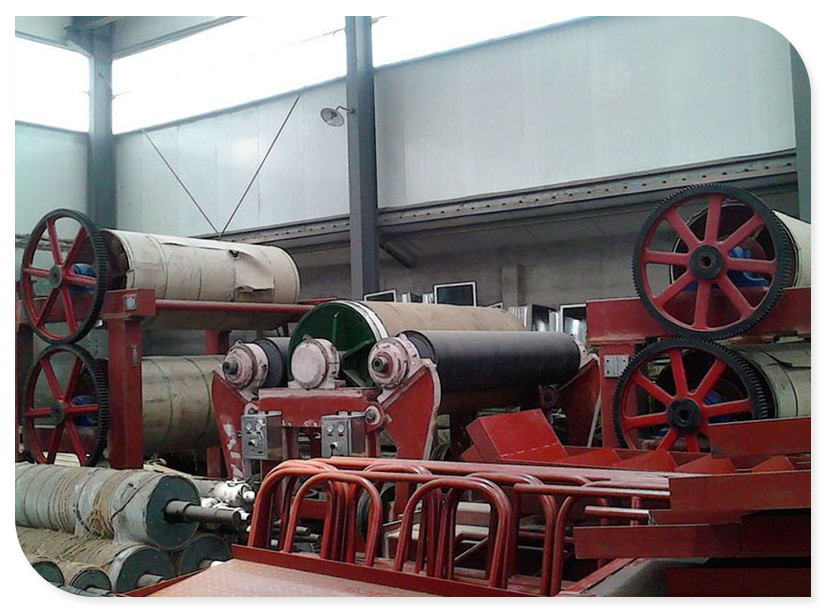

Paper coating machine for thermal paper with long image life characteristic

1.Overview

1320 thermal paper coating machine mainly include single-station release paper unit, bladecoating, pneumatic open type hot air drying system, back coating wet Mizube, dryer coherentstates finishing department, two roll calender machines, single station automatic correction reel,drive unit and electrical control nine parts. Drives with frequency step motor drive. The machinehas a simple structure, easy operation and maintenance, loss of paper rate, etc.

2.Process:

Process: unwinding roll- scrape-knife coating device-three drying ovens (four meters each drying oven) -scrape-knife coating device-four drying ovens (four meters each drying oven) -back wet device -3-1350 debugging mode Cylinder dryer-two roll calender machines-level rewinding roll device, please see process flow diagram

3.hot air drying system

This machine adopts three 4 m hot air oven, oven a total length of 12 meters. The system includes hot air oven, heating fans, heat exchangers, thermometer and hot air ducts.

Heat oven to pneumatic open type oven, oven body is made of welded steel , insulation thickness of 80 mm , box packaging material selection, color steel plate, galvanized sheet inside the package chosen . Hot air nozzle is stainless steel making . Each oven is equipped with four guide rollers ,guide rollers with gear .

Air within the oven through the fan recycling, and add fresh air , the temperature of the air in the heat exchanger by regulating the steam pressure control .

1320 thermal paper coating machine mainly include single-station release paper unit, bladecoating, pneumatic open type hot air drying system, back coating wet Mizube, dryer coherentstates finishing department, two roll calender machines, single station automatic correction reel,drive unit and electrical control nine parts. Drives with frequency step motor drive. The machinehas a simple structure, easy operation and maintenance, loss of paper rate, etc.

2.Process:

Process: unwinding roll- scrape-knife coating device-three drying ovens (four meters each drying oven) -scrape-knife coating device-four drying ovens (four meters each drying oven) -back wet device -3-1350 debugging mode Cylinder dryer-two roll calender machines-level rewinding roll device, please see process flow diagram

3.hot air drying system

This machine adopts three 4 m hot air oven, oven a total length of 12 meters. The system includes hot air oven, heating fans, heat exchangers, thermometer and hot air ducts.

Heat oven to pneumatic open type oven, oven body is made of welded steel , insulation thickness of 80 mm , box packaging material selection, color steel plate, galvanized sheet inside the package chosen . Hot air nozzle is stainless steel making . Each oven is equipped with four guide rollers ,guide rollers with gear .

Air within the oven through the fan recycling, and add fresh air , the temperature of the air in the heat exchanger by regulating the steam pressure control .

design speed:300m/min

working speed: 200-250m/min

working speed: 200-250m/min

gram of base paper: 40-100g/㎡

width of base paper: 1320mm

max rewing diameter: 1400m

coating way: blade coating

gram of coating: 5-8g/m²

dry: hot air from one side

finishing: dry&cylinder

Send product request

Other supplier products

| Paper coating machine for thermal paper with long image life characteristic | 1.Overview1320 thermal paper coating machine mainly include single-station release paper unit, bladecoating, pneumatic open type hot air drying sys... | |

| Paper coating line for thermal direct paper | 1.paper coating machine mainly include single-station release paper unit, blade coating, pneumatic open type hot air drying system, back coating we... | |

| cast coated paper coating machine | Itisaoff-machinecoatingmachineryusedforthecoatingofsidedcoatedpaperofbasispaperweightis50-120g/m²i. Coatingamountper8-15g/m²,workingspeed... | |

| customized single/double side art paper coating machine | ivory board paper,art paper coating machine Itisaoffmachinecoatingmachineryusedforthecoatingofsidedcoatedpaperofbasispaperweightis50-120g/m&sup... |

Same products

| SBD series double servo semi-automatic box nailing machine | Seller: 769251 | Changing the size within one minute◆ Easy operation and no needs of experiences◆ The machine coul... | |

| Guangzhou Licensing Services,UPS customs clearance solution | Seller: SeeHog Import & Export Trading Co., Ltd | Seehog Guangzhou Customs clearance agentclear import and export consignments at chinaPorts for Ai... | |

| Flat bed automatic die cutting machine | Seller: Weifang Swan Machinery Co. Ltd. | ||

| HV-60A3-3S Book Glue Perfect Binder | Seller: Suzhou Hevotec Machinery Co., Ltd | HV-60A3-3S Book Glue Perfect Binder Model HV-60A3-3S Controlpanel LED... | |

| HV-60A3-3ST Book Glue Binding Machine | Seller: Suzhou Hevotec Machinery Co., Ltd | HV-60A3-3ST Book Glue Binding Machine Model HV-60A3-3ST Controlpanel ... |