Stock and stone crushing machine for waste recycling

Introduction Overview of Stock and stone crushing machine for waste recycling:

Stock and stone crushing machine for waste recycling is the crusher equipment appeared earlier, because of its simple structure, strong, reliable, easy maintenance and repair and production and construction costs are relatively small, so until now is still widely in the metallurgical, chemical, building materials, electric power and other industrial sectors.

Application of Stock and stone crushing machine for waste recycling:

- Stock and stone crushing machine for waste recycling mainly used for a variety of ore and large pieces of material of medium size crushing.

- Stock and stone crushing machine for waste recyclingwidely used in mining, metallurgy, building materials, roads, railways, water conservancy,chemical and other industries.

Working principle of Stock and stone crushing machine for waste recycling:

The main machine, moving jaw, eccentric shaft, jaw plate, brackets and other components, the motor through the V-belt rotation eccentric shaft, the moving jaw by the adjusted track movement, which will crush the cavity of the material broken.

The frame is a single integral cast steel structure. The front wall of the frame is equipped with a fixed jaw fastened with a wedge bolt. A side guard is installed on the side wall of the frame around the crushing chamber to prevent the wear of the frame side wall. The movable jaw is a molded steel piece with a movable jaw plate on its front and its upper part is suspended from the frame by eccentric shaft and roller bearing. The lower part is supported on the bracket and is in rolling contact with the elbow plate. Terminal with flywheel and pulley.

The other end of the brackets is supported on the adjustment seat and is brought into contact with the bearing. The brackets are supported by the movable jaw, and the material which can not be crushed into the crushing chamber can not be broken. Insurance role, that is, their own rapid break, while the protection of other parts from damage.

The adjustment seat is installed in the chute on both sides of the frame and is in close contact with the wedge. When the discharge port needs to be adjusted, the nut is right-handed and the wedge is raised immediately by the wrench. Move, the discharge port from big to small, and vice versa from small to big. Structural features: The machine is mainly composed of frame, moving jaw, eccentric shaft, jaw plate, brackets and other components, the motor through the V-belt rotation eccentric shaft, the moving jaw by the adjusted track to move, so the crushing chamber The material is broken.

Technical parameter table of Stock and stone crushing machine for waste recycling:

|

Model |

Feed size (mm) |

Feed granularity (mm) |

Productivity (t/h) |

Adjustment range (mm) |

Motor power (kw) |

Dimensions (mm) |

Weight (t) |

|

WPE-150×250 |

150×250 |

125 |

1-5 |

10-40 |

875×758×850 |

||

|

WPE-150×750 |

150×750 |

125 |

5-16 |

10-40 |

15 |

1200×1530×1060 |

|

|

WPE-250×400 |

250×400 |

210 |

5-20 |

20-60 |

15 |

1450×1315×1296 |

|

|

WPE-400×600 |

400×600 |

340 |

16-65 |

40-100 |

30 |

1565×1732×1586 |

|

|

WPE-500×750 |

500×750 |

425 |

45-100 |

50-100 |

55 |

1890×1918×1870 |

|

|

WPE-600×900 |

600×900 |

500 |

90-180 |

65-160 |

55-75 |

2305×1840×2298 |

|

|

WPE-750×1060 |

750×1060 |

630 |

110-260 |

80-140 |

110 |

2450×2472×2840 |

28 |

|

WPE-900×1200 |

900×1200 |

750 |

160-410 |

95-165 |

110 |

3335×3182×3025 |

50 |

|

WPE-1000×1200 |

1000×1200 |

850 |

250-480 |

195-265 |

110 |

3435×3182×3025 |

57 |

|

WPE-1200×1500 |

1200×1500 |

1020 |

350-800 |

150-300 |

160 |

4200×3732×3843 |

|

|

WPEX-250×750 |

250×750 |

210 |

15-30 |

25-60 |

22 |

1667×1545×1020 |

|

|

WPEX-250×1000 |

250×1000 |

210 |

16-52 |

25-60 |

30-37 |

1530×1992×1380 |

|

|

WPEX-250×1200 |

250×1200 |

210 |

20-60 |

25-60 |

37 |

1900×2192×1430 |

|

|

WPEX-300×1300 |

300×1300 |

250 |

20-90 |

25-105 |

75 |

2720×1950×1600 |

11 |

Send product request

Other supplier products

| Tyre type Mobile Stone crushing plant for highway | Introduction Overview of Tyre type Mobile Stone crushing plant for highway: Tyre type Mobile Stone crushing plant for highway is a series of rock ... | |

| WMSC municipal waste management to compost | Municipal waste management to compost can be from the source to eliminate landfill and incineration of environmental pollution problems, saving a l... | |

| WYA series circular vibrating screen for mining | WYA series circular vibrating screen for mining Uses and characteristics of WYA series circular vibrating screen for mining: The circular traject... | |

| ZK linear vibrating screen | ZK linear vibrating screen Use: ZK linear vibrating screen, linear movement, suitable for coal preparation, coal washing, dressing, power and ot... | |

| High amplitude vibration screen, circular vibrating screen for mining | High amplitude vibration screen, circular vibrating screen for mining Applications of High amplitude vibration screen, circular vibrating screen f... |

Same products

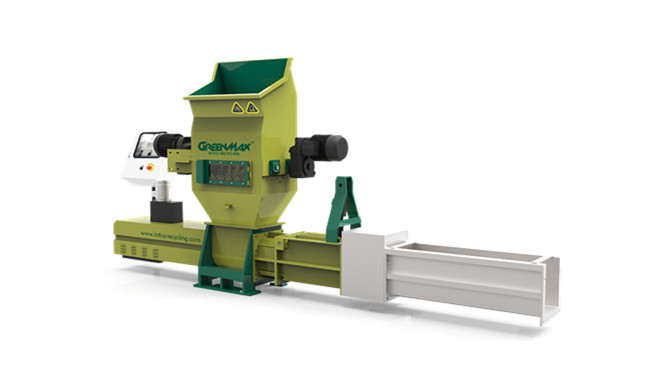

| GREENMAX Foam Densifier ZEUS C100 | Seller: INTCO Recycling | Polyethylene Foam| Polystyrene Foam Densifier Foam Densifier can prevent the compacted EPS, PE Fo... | |

| Customized Plastic Grinder Waste Crusher WHC800/600 | Seller: Wobide Machinery(Zhejiang)Co., Ltd. | 1.WHC series heavy-duty crushers are widely used in various of plastic products, such as PE, PP, ... | |

| Mobile Stone Crushing Plant | Seller: Henan Shengmao Machinery Co., Ltd | Product Description In order to meet customer’s special requirements, we developed . Cur... | |

| Plastic Pallet Crusher WPC1000/600 | Seller: Wobide Machinery(Zhejiang)Co., Ltd. | 1.WPC series plastic pallet crusher is specially designed and developed for plastic products with... | |

| GK-HGX Type Ash Calcium Powder Seperator | Seller: Guilin Mining Machinery Co., LTD. | GK-HGX type Ash CalciumPowder SeparatorModel: A type/B type/E type/F type GK-HGX type Ash Calcium... |