PC/PMMA/ABS/PS/PP sPC/PS/PP sheet production equipmentheet production line

PETG/APET/PP/PC/PS/ABS/PE/PMMA sheet production equipment is capable of continuously producing mono-layer or multi-layer PP/PE/ABS/PMMA/PC/PS/HIPS plate and sheet with the width less than 3000mm and thickness of 0.1-30mm. The products are widely used in the fields of refrigerator, air conditioner, auto, advertisement, and construction, environmental protection, etc. Extruder: Appropriate single-screw extruder(exhaust or not) should be chosen on the basis of different materials. Specially designed screw and advanced temperature controlling system ensure the good plasticization, high output and stable extruding. Screen changer and mould: The quick screen changer of hydraulic system ensures the short course of screen changing without material-leakage. Reasonable structure of mould should be chosen in terms of material, whereas moulds of clothes-rack mode are widely accepted to regulate flow-distribution and guarantee even thickness of plates (sheets). Three-roller calendaring machine: Inclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets). Temperature controller operates separately and gap among the three rollers can be adjusted freely, and the central roller has special design of regulating angle. Both ensure the excellent calendaring effect and even thickness of plates (sheets). Bracket of cooling roller: Equipped with corresponding guide roller, the cooling effect is better. In addition, the edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge. Landscape orientation cutting machine: It is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance. The winder: It is of friction winder and other forms as well can be supplied according to customers’requirements. Main technical parameters: Model Extruder Sheet width (mm) Thickness (mm) Traction speed(m/min) Production capacity(KG/H) JW-90 JW-90B×30 300-1200 0.15-50 5-20 300KG/H JW-120 JW-120B×30 800-2000 0.15-50 5-15 400KG/H JW-150 JW-150B×30 1200-3000 0.15-50 5-12 600KG/H

Other supplier products

|

|

PPR Pipe Production line |

PP-R/PP/PE plastic pipe extruding production line adopts unique design, seperated BM type high efficiency screw, high degree of automation, conveni... |

|

|

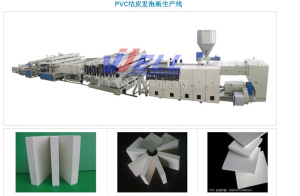

PVC Foam Board Production Line |

PVC skinning foaming board extrusion line adopts Celuka foaming technology. When compared with PVC free foaming board, PVC skinning foaming board n... |

|

|

PVC Foam Board Production Line |

PVC skinning foaming board extrusion line adopts Celuka foaming technology. When compared with PVC free foaming board, PVC skinning foaming board ... |

|

|

HDPE Large Diameter Hollow Wall Winding Pipe Production Line |

HDPE Large Diameter Hollow Wall Winding Pipe Extrusion Line contain profile tube extruder, melting connection extruder, winding forming machine, c... |

|

|

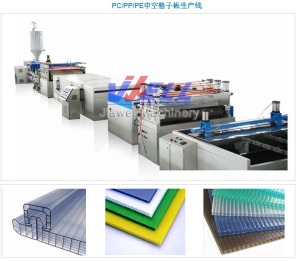

PC/PP/PE Hollow Sheet production line |

The set of the special equipment for directly extrusion of hollow grid plates,with the product surface being bright and clean,artistical and compre... |

All supplier products

Same products