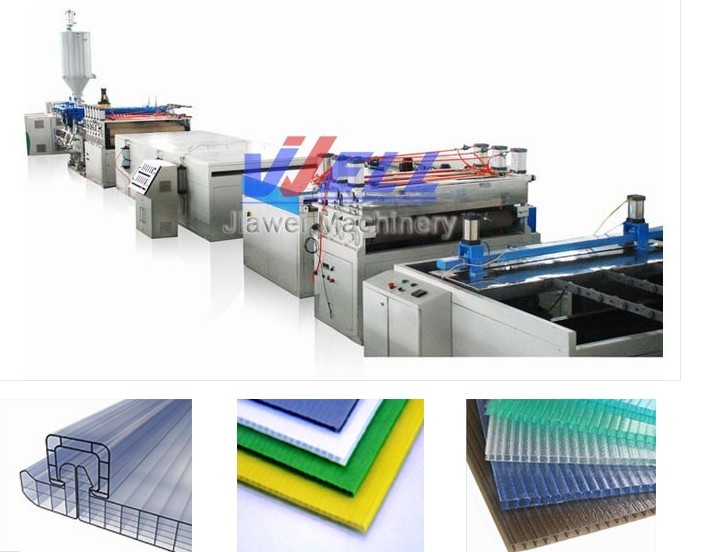

PC/PP/PE Hollow Sheet production line

The set of the special equipment for directly extrusion of hollow grid plates,with the product surface being bright and clean,artistical and compression resistant. This plate is widely used in the fields of construction,package and decoration. By replacing the molding unit,the set can produce not only the LDPE hollow grid plates, but the PP and PE transparent and thermal insulating hollow grid plates used in the agriculture and construction.

·The complete line is characterized by high output,little error of manufacture,easy operation,high automation. So it is in new or old domestic and foreigh customers good graces.

Main technical parameters:

| Host Model |

JW-150*25 Single screw extruder |

JW-120*25 Single screw extruder |

| Host Power(kw) |

75~90 |

55~75 |

| Shape model number |

2 |

2 |

| Pump power(kw) |

11 |

11 |

| Traction speed(m/min) |

0.5~5 |

0.5~5 |

| Traction power |

3 |

3 |

| Tangential speed |

44.6 |

44.6 |

| Production capacity |

120~300 |

65~190 |

Other supplier products

|

|

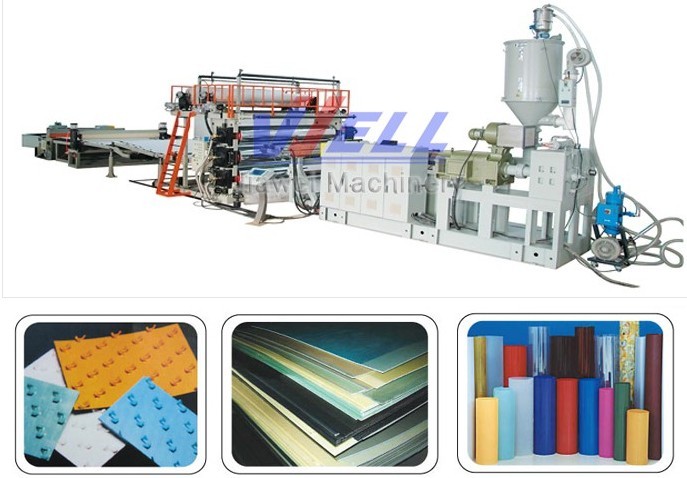

PC/PMMA/ABS/PS/PP sheet production line |

PETG/APET/PP/PC/PS/ABS/PE/PMMA sheet production equipment is capable of continuously producing mono-layer or multi-layer PP/PE/ABS/PMMA/PC/PS/HIPS ... |

|

|

PE heat preservation pipe production line |

This PE pipe machine is mainly used in producing PE large diameter tube, and its products are mainly applied to the outer layer of heating pipeline... |

|

|

Conical Twin-Screw Extruder |

Gentle molding design guarantees the quality of material.* Very much dependable valid design theory guarantee the dependable operating of extrusion... |

|

|

PE heat preservation pipe production line |

This PE pipe machine is mainly used in producing PE large diameter tube, and its products are mainly applied to the outer layer of heating pipeline... |

|

|

PE heat preservation pipe production line |

This PE pipe machine is mainly used in producing PE large diameter tube, and its products are mainly applied to the outer layer of heating pipeline... |

All supplier products

Same products