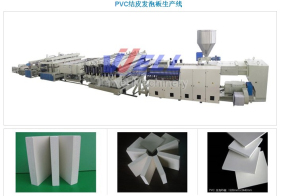

PVC wood plastic foam production line

PVC skinning foaming board extrusion line adopts Celuka foaming technology. When compared with PVC free foaming board, PVC skinning foaming board not only has much more smooth surface, but also has the more skin hardness, and the mechanics performance of the PVC skinning foaming board is also much better than the PVC free foaming board’s. PVC skinning foaming board extrusion line is composed of conical twin-screw extruder, die, vacuum calibration unit, ten-roller haul off unit and so on PVC skinning foaming board has a very wide application range, it is being used for cupboard, furniture board, advertisement board, construction decoration board, upholstery for train, car and ship. Main technical parameters: Model Foam board Half Foam board Product Width(mm) 700-1220 1220-1600 Thickness(mm) 5-25 5-18 Extruder JW130/21 JW80/156 Max extrusion production(Kg/h) 720Kg/h 400Kg/h Main motor power(Kw) 132Kw 75Kw

Send product request

Other supplier products

| AL-PE-AL-aluminum plastic composite panel production line | The WEIER-1300 ACP production line is special equipment which is used for making aluminum-plastic board. ACP as the new building material has so ma... | |

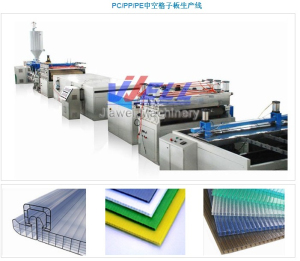

| PC/PP/PE Hollow Sheet production line | The set of the special equipment for directly extrusion of hollow grid plates,with the product surface being bright and clean,artistical and compre... | |

| Multi-layer co-extrusion sheet &plate extrusion line | Multi-layer co-extruding sheet&plate line can produce various material compound sheet &plate , PP/EVA/EVOH/PP; PP/PE/PS; PMMA/ABS and so o... | |

| PE heat preservation pipe production line | This PE pipe machine is mainly used in producing PE large diameter tube, and its products are mainly applied to the outer layer of heating pipelin... | |

| Single-layer, multi-layer sheet production line | Multi-layer co-extruding sheet&plate line can produce various material compound sheet &plate , PP/EVA/EVOH/PP; PP/PE/PS; PMMA/ABS and so o... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |