Plastic template building

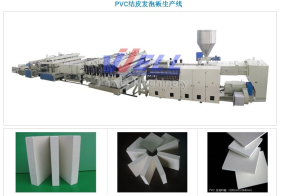

PVC skinning foaming board extrusion line adopts Celuka foaming technology. When compared with PVC free foaming board, PVC skinning foaming board not only has much more smooth surface, but also has the more skin hardness, and the mechanics performance of the PVC skinning foaming board is also much better than the PVC free foaming board’s. PVC skinning foaming board extrusion line is composed of conical twin-screw extruder, die, vacuum calibration unit, ten-roller haul off unit and so on PVC skinning foaming board has a very wide application range, it is being used for cupboard, furniture board, advertisement board, construction decoration board, upholstery for train, car and ship. Main technical parameters: Model Foam board Half Foam board Product Width(mm) 700-1220 1220-1600 Thickness(mm) 5-25 5-18 Extruder JW130/21 JW80/156 Max extrusion production(Kg/h) 720Kg/h 400Kg/h Main motor power(Kw) 132Kw 75Kw

Other supplier products

|

|

HDPE large-diameter insulation equipment |

This PE pipe machine is mainly used in producing PE large diameter tube, and its products are mainly applied to the outer layer of heating pipelin... |

|

|

PP/PSthree-layer coextrusion sheet production line |

Multi-layer co-extruding sheet&plate line can produce various material compound sheet &plate , PP/EVA/EVOH/PP; PP/PE/PS; PMMA/ABS and so o... |

|

|

PE Water ring pelletizing line |

This water ring pelletizing line is mainly used for PE, PP, PET compounding, filling, reinforcing, pelletizing and modification of plastic granules... |

|

|

PVC Pipe Extrusion Line |

With 20 years experience of design and manufacturing, adopt conical twin screw extrude, ensure better quality and high output. We can allocate the ... |

|

|

WPC Wood-plastic extrusion line |

The specially-designed screw barrel, mold and extruding machine production of wood-plastic products processing production process. Extruder Single... |

All supplier products

Same products