Screw and barrel for plastic machine

Ningbo Tianze Machinery Technology Co., more infor pls find sales(at)tizatech.com

We machine, hard-surface,grind and polish to precision tolerances in injection screws manufacturing. Special hard-surfacing alloys are made with Nickel, Tungsten-Carbide and Molybdenum.

In injection molding machines, the plasticizing unit: the screw and cylinder turns solid resin into uniform melt. In the plasticizing process, the most important elements include selecting materials suitable for various plastic resins, mechanical design, and injection molding parameters (melt temperature, metering, speedtime, back pressure, holding pressure, etc.).

Components of Plasticizing Unit:

Barrels, Screws, Screw Tip Valves, Screw Tip Assemblies, Check Ring, Rear Seat, End of Barrel, Barrel End Cap Adapters, Nozzle Bodies and Nozzle Tips, Nozzles

Screw Design:

Screw design must focus on mixing, pumping, melting and conveying tasks. Injection screws must be designed in accordance with the properties of the polymer to realize the best-level kneading and plasticizing performance. Application specific elements that affect output include:

• Screw total length • Feed zone • Transition zone • Metering zone • Channel depth

• Helix angle • Flight clearance • Flight width • Pitch/Lead (spacing) • Screw O.D. /Barrel size

• Nozzle & tip design• Flight length • Material to be processed• Volumetric feeding • Continuous feeding

• Steel and Finishes• Wear and durability• Temperatures control

We meet and exceed our customers expectations by offering:

Carefully engineered screw geometry to match the exact needs of your process.

Reduced cycle times and longer machine life.

Pairing of base materials and surface treatments to maximize screw life.

Screw recovery solutions for high performance and multiple applications.

Quality inspections with every step of the process to create customized parts specific to our customers demands.

Expertly manufactured parts that exceed OEM tolerances.

Send product request

Other supplier products

| EXTRUDER BARREL SCREW for PVC PLASTIC | EXTRUDER BARREL SCREW Raw Material : 38CrMoALA(SACM645) 1.8550 Bimetal Stainless Tough Harden Tool Steel Surface Roughness : Ra 0.4um Linearity ... | |

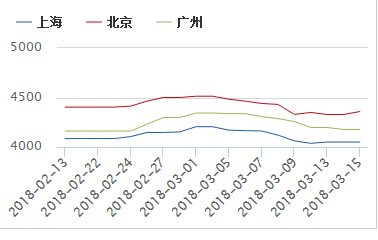

| Screw Barrel --- Polypropylene prices continue to slide | The spot resin markets started last week slowly but became quite active later in the week, reports the PlasticsExchange (Chicago) in its Market Upd... | |

| Screw barrel for plastic rubber production machine IMM Extrusion machine plastic pipe film | DearManager , Good morning to you ! Over 29 years experience in Screw barrel line ,with a much lower price with the same quality and thewarrant... | |

| 2017 Tizatech Screw Barrel for Plastic Production Machine | Hi Manager , Any inquire about screw barrel for Plastic rubber productionmachine ? We are glad to provide our best service and price for your ref... | |

| Ningbo Tizatech Screw Barrel for Blow Film Extrusion Machines From China | More info pls feel free to findsales(at)tizatech.com We are good at ranger of products and applications : PP PA EVOH MLLDPE LLDPE HDPE Insulation... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |