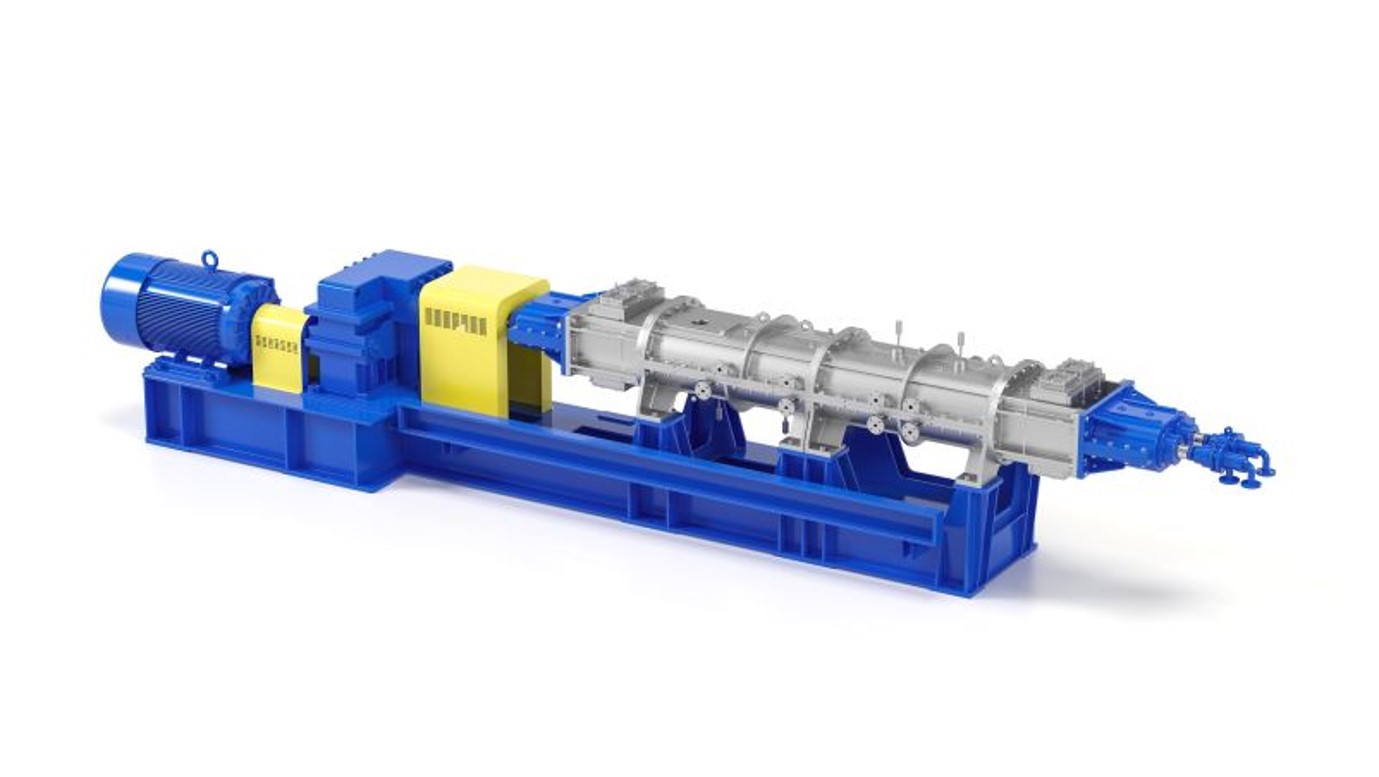

PVC Floor leather production line, wide floor leather production line

All supplier products

PVC Floor leather production line, wide floor leather production line

PVC floor uses high-grade PVC resin as the main raw material, adding amount of filler and stabilizer, plasticizer, UV absorbers and other auxiliary additives, through the process of mixing, extrusion, cooling, rewinding, metering, packaging etc. to form new type water-proof material.

PVC Floor leather (also known as rolled floor), a new type of floor material, belongs to plastic product, is one of the necessary ground materials for modern furnishing decoration, thickness of 1.5 mm or more, wear-resistant layer of more than 0.1. Plastic floor leather, which belongs to the soft floor, which is made of polyvinyl chloride resin as the main raw material, added with some additives, by coating or calendering on continuous sheet base to form floor roll.

The advantages of PVC floor leather

PVC Wide floor leather production line has the advantages of compact structure, convenient operation, can produce single-layer and multi-layer composite products just by equipping with different components according to customer s requirements; it can also equip with the unwinding device, to produce reinforced products or surface composite non-woven fabrics and PVC decorative film products etc.

Qingdao Canplast Machinery welcome friends around the world to inquire with PVC Floor leather production line.

Service for PVC Floor leather production line

Pre-Pre-sale customers can consult to our company for various technique and business, our company will provide related information to facilitate reference, and provides the corresponding marketing information, sales price, sales method, to help customers know the entire market.

In-sIn Insale after the two sides signed the contract, our company will provide corresponding design of water, electricity, air, ground installation diagram, according to customer requirements and the actual situation. After the production completed, we should inform customer in advance in order to inspect machine testing, and provide various convenience like airport pick-up, catering, hotel booking etc.

PVC Floor leather production line After-sales after equipment completed in our company and debugging qualified, equipment arrived customer is factory, our technician should arrive customer is factory in time at customer is requirements to do installation, commissioning, personnel training, technology transfer, until the user can operate independently, and produce qualified products.

Formulation and technical support all production equipment of our company are free of charge to provide the production formula and debug the equipment according to the formula. Any problem in the production process can call us for consultation.

Maintenance and warranty for equipment all equipment of our company are provided with corresponding accessories, the warranty period of our equipment is one year, operation manual and maintenance manual are offered.

PVC Floor leather production line Main technical data

|

Extruder |

SJ-65/132 |

SJ80/156 |

SJ-92/188 |

SJ-120/30 |

|

Screw ratio (L/D) |

22 1 |

22 1 |

281 |

30 1 |

|

Sheet width (mm) |

1220-1500 |

1200-2100 |

1200-4000 |

1200-4000 |

|

Sheet thickness(mm) |

1-5 |

1-5 |

1-5 |

1-5 |

|

Main motor power (kw) |

37 |

55-75 |

110-160 |

160-315 |

|

260 |

400 |

600 |

500-1000 |

Qingdao Canplast Machinery Co., Ltd Our main products are PP-PC hollow grid board production line, PE, PP, PS, PVC Thick Board Production Line, PVC flooring extrusion line, PVC, TPU, PE, EVA wide water-proof geomembrane production line, WPC furniture-cabinet board production line, PP-PE-PVC Wood Plastic Composite Profile Extrusion Line, PP-R Cold-Hot Water Supply Extrusion Line, PVC Pipe Extrusion Line, PE-PP Gas/Water Supply Pipe Extrusion Line.

Send product request

Other supplier products

| WPC cabinet board production line | WPC cabinet board production line Wood Plastic furniture plate production line Wood kitchen board sheet production line, also known as PVC wood fur... | |

| Three layer WPC foam building template production line | Three layer WPC foam building template production line Three layer WPC foam building template production line can be also called as PVC wood plasti... | |

| PVC Floor leather production line, wide floor leather production line | PVC Floor leather production line, wide floor leather production line PVC floor uses high-grade PVC resin as the main raw material, adding amount o... | |

| PE, PP foam board production line | PE, PP foam board production line Characteristics of PE, PP foam board production line PP foam products have the advantages of excellent heat resis... | |

| Plastic hollow grid sheet production line | Plastic hollow grid sheet production line Brief introduction of plastic hollow grid sheet production line, PC, PE, PP hollow grid sheet production ... |

Same products

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... | |

| SUNKAIER SK3000S-EXTRUDING KNEADER REACTOR | Seller: Jiangsu Sunkaier Industrial Technology Co., Ltd. | SUNKAIER SK3000S-EXTRUDING KNEADER REACTOR DESCRIPTION SK3000S Kneader is ideally suited fo... | |

| PVC WPC Panel Board Extrusion Line | Seller: JWELL MACHINERY(CHANGZHOU)CO., LTD | Jwell extrusion has specialized in plastic extrusion machines and complete solutions for over 25 ... | |

| PVC Window Profile Extrusion Line | Seller: JWELL MACHINERY(CHANGZHOU)CO., LTD | Our high quality PVC window profile extrusion line equipped with special conical twin screw extru... |