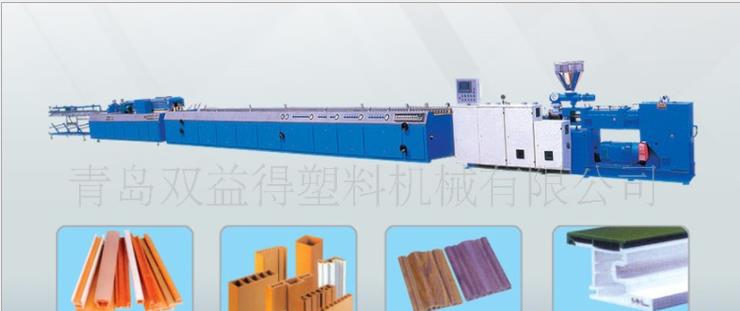

Plastic extrusion profile production line

1. Conical twin screw pipe and profile extrusion equipment is equipped with corresponding molds and auxiliary equipment, which can be used for extrusion molding of rigid PVC pipes and PVC profiles.

2. Hard PVC pipe equipment model: AFP63, AFP110, AFP250, AFP400, AFP630, AFP800

3. Hard PVC profiled equipment model: AFF150, AFF300, AFF400, AFF1000, AFF1200

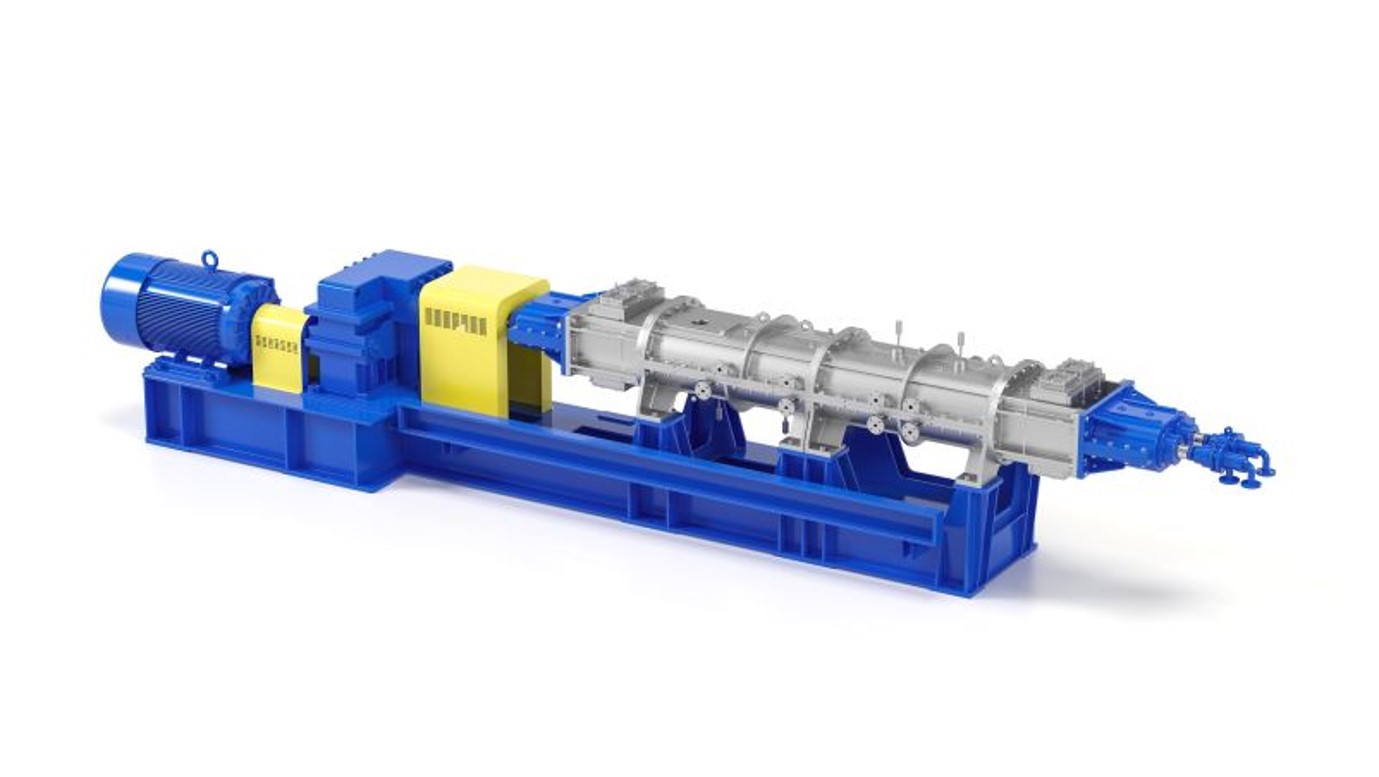

4. Conical twin screw extruder features:

● Unique screw design, short residence time of the material in the barrel, good mixing and plasticizing effect

Adopt high-quality reduction gear box, beautiful appearance, stable operation and low noise;

The barrel adopts copper fin ceramic heater and air cooling system, which has good heating and cooling effects and accurate temperature control;

Screw adopts core temperature control system;

The use of a vacuum exhaust system can discharge the moisture and volatile gases in the material, which can improve the quality of the product;

The main motor adopts thyristor DC governor or variable frequency governor. The output torque of the motor is stable and stepless speed regulation can be realized.

Suitable for powder PVC heat sensitive material processing.

Vacuum setting device: vacuum spraying box for pipes, cooling box for spraying pipes, shaping table for special profiles, all parts in contact with water are made of stainless steel.

Traction machine: two-claw, four-claw, six-claw, and eight-claw pipe haulers, a series of two-track profile traction machines to meet the production requirements of different pipes and profiles.

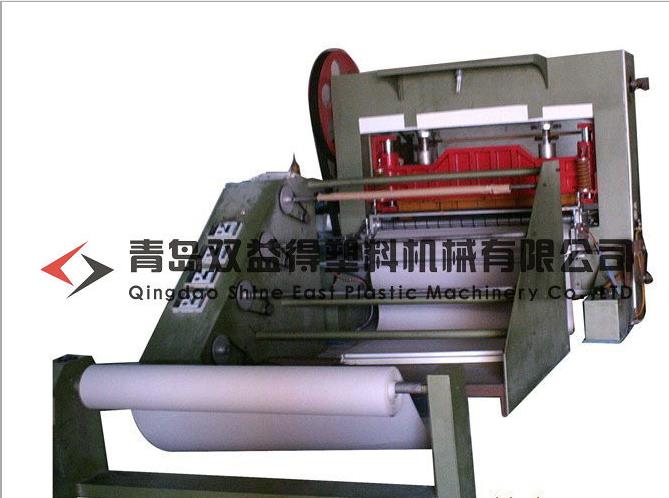

Cutting machine: chipless cutting, sawing, planetary sawing (with chamfering).

Expanding equipment for rigid PVC pipes.

Stacking device: Automatic flap or roller stacking device.

There are a variety of electrical control systems to choose from (such as PLC automation control systems), stable production, simple and easy control.

Other supplier products

All supplier products

Same products