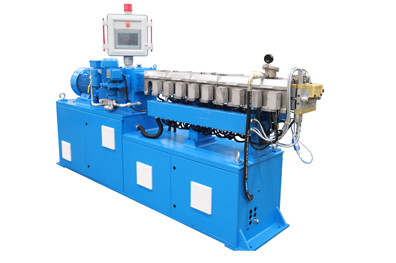

SK Series Co Rotating Twin Screw Extruder

SK series twin screw extruder is the crystallization of more than 30 years'experience in the equipment manufacturing industry, more than 400 kinds of material technology application and thousands of working conditions verification of KY. Screw diameter can be selected from 26 mm to 135 mm.

SK Series double screw extruder machineadopts the welding and manufacturing process of international leading standards. It provides the best stability and reliability in operation and has successfully succeeded in replacing imported products in China.

SK seriestwin screw extruderis the crystallization of more than 30 years'experience in the equipment manufacturing industry, more than 400 kinds of material technology application and thousands of working conditions verification of KY. Screw diameter can be selected from 26 mm to 135 mm.

SK Series double screw extruder adopts the welding and manufacturing process of international leading standards. It provides the best stability and reliability in operation and has successfully succeeded in replacing imported products in China.

SK Series Twin screw extruders have the following advantages:

High-efficiency transmission system

The SK Series Mini Twin screw extrusion machineadopts the high speed and high torque transmission system of Henschel of Germany. The screw has a maximum speed of 900 rpm. and a torque of 13 Nm/cm³. The system of K Series Twin screw extruder adopts the latest design of Henshl, and the overall strength and gear system stability are greatly improved. At the same time, the system is smaller and equipped with more powerful lubrication and cooling system, which enables users to use extruders safely and quietly.

British BiBBY torque limiter with high sensitivity and reliability can effectively avoid equipment shutdown due to improper operation or accidental overload.

Siemens's global joint insurance ILE0 series inverter motor has the characteristics of high efficiency, energy-saving, safety and so on. It provides technical support and service for localization.

Optimizing Processing Section

The processing section of the SK series double screw extruder can be flexibly configured for transportation, plasticization, mixing, shearing, homogenization, devolatilization, and pressure according to the technological requirements of users' materials.

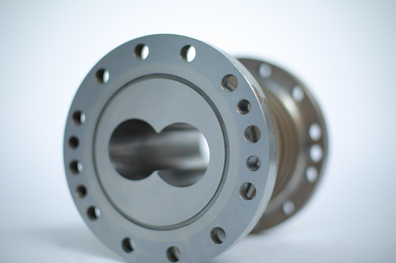

The screw and barrel of this kind ofplastic extrusion equipment for salecan be made of HIP powder metallurgy material, which can achieve high wear resistance, high corrosion resistance and other extensive fields of operation.

The involute spline of the German standard (DIN5480) is adopted to meet the requirements of higher torque and higher speed.

Optimized screw size-diameter ratio (D0:D=1.55), reliable inter-model amplification effect

Internet-based New Generation Control System

The control system of SK series twin-screw extruder can choose conventional instruments, PLC, PCC, DSC to meet different needs.

Modular design, the touch screen can be compactly installed on the mainframe

Customized programming design is satisfied with the upstream and downstream matching equipment of different mixing projects

Provide formulation, project management functions, process and production data visualization

Integrating computer technology, mobile Internet technology and industrial automation technology to realize real-time data management and control of multi-terminal

Parameter of SK Series Co-rotating Twin Screw Extruder

|

SK Series Co-rotating Twin Screw Extruder Model |

Production capacity kg/hr (reference value) |

|||||||

|

Material Process Category |

Typical Material |

SK26 |

SK36 |

SK53 |

SK63 |

SK73 |

SK96 |

SK136 |

|

Filling modification |

PE, PP, EVA, etc. + calcium carbonate, talcum powder, titanium dioxide |

5~10 |

45~90 |

150~300 |

300~500 |

600~800 |

1200~1500 |

1800~2700 |

|

ABS, PC, PS, etc. + aluminum hydroxide, magnesium hydroxide, antimony oxide |

||||||||

|

PP, PA, ABS, etc. + iron powder, magnetic powder, ceramic powder |

10~20 |

90~135 |

180~300 |

380~500 |

700~900 |

1300~1800 |

1800~3000 |

|

|

blending modification |

PP, PE, PS + SBS; PP, PA + epdmpp + NBE; EVA + silicone rubber, etc |

5~10 |

60~100 |

150~240 |

270~450 |

500~750 |

1000~1700 |

1600~3000 |

|

PE, PA, PC, CPE + ABS; ABS + TPU; PBT + pet; PP + PE, etc |

5~10 |

45~90 |

120~240 |

270~380 |

450~600 |

1000~1500 |

1200~3000 |

|

|

Masterbatch |

PE, PP, ABS, EVA, PS, etc. + pigment and other additives |

3~8 |

45~75 |

150~230 |

270~360 |

380~500 |

900~1200 |

900~1800 |

|

Functional Masterbatch |

Degradable masterbatch: PE, PS, etc. + starch, etc |

3~8 |

45~90 |

140~230 |

230~330 |

380~500 |

900~1200 |

900~1800 |

|

Flame retardant masterbatch: PP, PA, ABS, PBT, etc. + flame retardant and other auxiliaries |

3~8 |

60~100 |

150~270 |

300~450 |

500~750 |

1200~1700 |

1500~2700 |

|

|

Double control masterbatch: PE + antifogging agent, stabilizer, etc.; high insulation masterbatch; cooling masterbatch; rheological modified masterbatch |

3~8 |

45~75 |

100~150 |

270~360 |

420~540 |

900~1200 |

900~1800 |

|

|

Carbon black masterbatch: PE, EVA, ABS, etc. + carbon black |

3~8 |

30~60 |

90~150 |

230~330 |

380~500 |

800~1000 |

900~1500 |

|

|

Glass fiber (carbon fiber) reinforced modification |

PP, PBT, ABS, as, PA6, PA66, PC, POM, PPS, pet, etc. + long fiber or short fiber or whisker |

5~10 |

75~120 |

180~270 |

300~450 |

450~700 |

900~1400 |

1500~2400 |

|

PP, PBT, ABS, as, PA6, PA66, PC, POM, PPS, pet, etc. + carbon fiber |

5~10 |

45~90 |

150~240 |

270~330 |

380~500 |

900~1200 |

1000~2100 |

|

|

Special materials |

EVA hot melt adhesive, polyurethane |

3~8 |

45~90 |

90~140 |

150~230 |

300~380 |

700~800 |

700~1500 |

|

Fluororubber, fluoroplastics |

3~8 |

30~60 |

60~120 |

150~230 |

230~300 |

600~750 |

700~1400 |

|

|

Optical cable coating material, acetate fiber, PP cigarette filter material |

3~8 |

45~90 |

150~230 |

300~380 |

450~600 |

1200~1500 |

1500~2400 |

|

|

TPR shoe sole |

3~8 |

90~150 |

230~300 |

450~500 |

700~800 |

1300~1700 |

1500~3000 |

|

|

Luminescent plastics, antibacterial plastics, UV resistant plastics, PE crosslinkable tube materials |

3~8 |

60~90 |

180~270 |

330~450 |

500~600 |

900~1200 |

1000~1800 |

|

|

Various cable materials |

HDPE, LDPE, LLDPE, MDPE insulation material and sheath material; PE radiation crosslinking cable material; PE silane crosslinking cable material |

3~8 |

45~90 |

150~230 |

270~380 |

450~600 |

750~1000 |

1000~1700 |

|

Flame retardant polyolefin cable material, PP cable material |

3~8 |

90~120 |

180~270 |

380~450 |

600~700 |

1100~1400 |

1200~1800 |

|

|

Low smoke and low halogen flame retardant PVC cable material |

5~10 |

30~60 |

120~180 |

230~300 |

380~500 |

800~1000 |

900~1500 |

|

|

Reactive extrusion |

Polyamide polycondensation, polyester melt polymerization, polyurethane addition polymerization, polycarbonate polycondensation, bulk continuous polymerization of POM |

1~2 |

30~50 |

150~230 |

300~380 |

450~600 |

750~900 |

700~1500 |

|

Post treatment of exhaust devolatilization |

Chlorinated polypropylene, super absorbent resin, K-Resin, chlorosulfonated polyethylene, fluoro rubber, etc |

1~2 |

Max75 |

Max150 |

Max300 |

Max450 |

Max900 |

Max1500 |

|

powder coating |

Polyester type, epoxy type, propyl ester type, polyurethane type, acrylate type, etc |

3~8 |

150~230 |

300~450 |

600~750 |

1000~1200 |

2100~2300 |

2200~4500 |

Send product request

Other supplier products

| HK Series Co Rotating Twin Screw Extruder | Nanjing KY provides more material selections for the process parts of the HK Series co rotating twin screw extruder. Besides standard nitriding ste... | |

| Extruder Parts | Founded in 1993, Nanjing KY Chemical Machinery Co., Ltd. is currently one of the largest parallel co-rotating twin screw extrusion machinesuppliers... | |

| HK Large Extruder Production System | KY also offers a larger-scale HK twin screw extruder, with the commonly used screw diameters ranging from 110 mm to 165 mm (HK110-165) available fo... | |

| KY-Lab Twin Screw Extruder | Overview of KY-Lab Scale Twin Screw Extruder Since its establishment in 1993, KY has been devoted to the development and manufacture of small labo... | |

| Barrels | The body of the basic grade barrel is made of 45 # steel. The liner of the barrel is made of basic alpha-101 bimetallic material. The high-grade b... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |