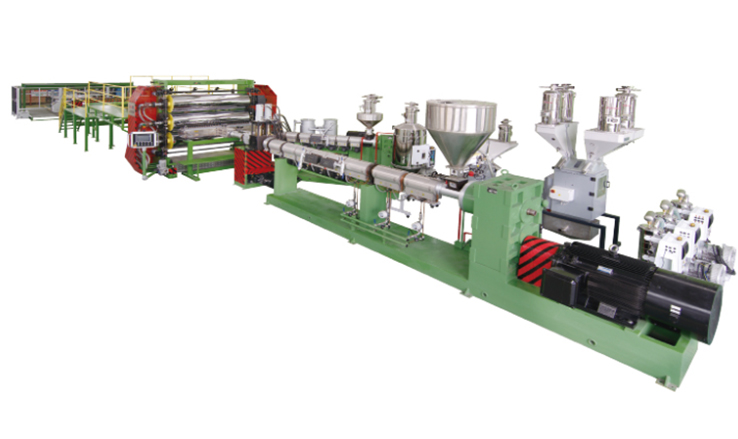

Film Extrusion Line

Film extrusion lineis a kind of screw plastic film extruder. The working mechanism of screw plastic extruder is to fully plasticize the materials by relying on the pressure and shear force generated by screw rotation and evenly mix and shape through the die; Therefore, sometimes one film extrusion machinecan complete a series of processes such as mixing, plasticization, and molding at the same time, so as to realize continuous production.

Jwell plastic extrusion company specializes in providing various film extrusions production lines and film extruders for sale, such as POE/EVA photovoltaic adhesive film production line, TPU casting film production line, TPU invisible car clothing production line, etc. the products from film extrusion line involve various fields such as photovoltaic, automobile, new energy, sports, and fitness equipment, and the products have the advantages of mature technical level, stable equipment use, high output, low energy consumption, fast after-sales and so on.

Types of Film Extrusion Line

LFT/CFP/FRP/CFRT Continuous Fiber Reinforced Composite Production Line

The continuous reinforced fiber composite production line developed by jwell company adopts automatic continuous unwinding of multiple groups of spindles, one-step prepreg and drying molding.

ASA Film Extrusion Line

ASA film is a film made of polyvinyl chloride, polyethylene, polypropylene, polystyrene, and other resins for packaging and film coating. Plastic packaging and plastic packaging production. Products account for an increasing share in the market, especially composite plastic flexible packaging and surface coating of building materials have been widely used.

TPU Film Extrusion Line

TPU film extrusion production line of jwell company adopts high-speed extrusion calendaring and tape casting, with excellent and controllable product quality, product thickness in the range of 0.01-2.0mm and width of 1000-3000mm.

EVA/POE Film Extrusion Line

EVA / POE adhesive film production line is used in solar photovoltaic power station, building glass curtain wall, automobile glass, functional shed film, packaging film, hot melt adhesive.

PE Breathable Film Extrusion Line

LDPE is low-density polyethylene, also known as high-pressure polyethylene. It has excellent chemical stability, heat sealing, water resistance, and moisture resistance, freezing resistance, and boiling ability. It is commonly used as the inner film of composite flexible packaging materials. At present, it is also the most widely used and most used plastic packaging film.

Stretch Film Extrusion Line

Stretch Film Extrusion Line is a film made of polypropylene resin, such as BOPP and CPP film production lines. The products can be used in food, medicine, chemical industry, and other fields, among which food packaging and other fields are the most widely used.

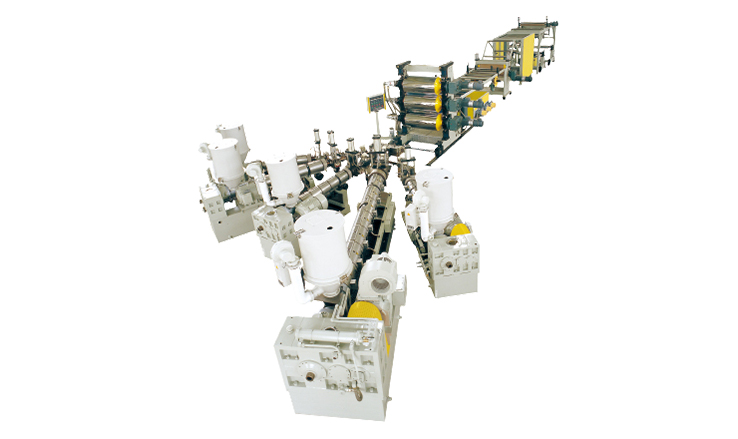

Multilayer Extruder Machine

Due to the increasingly stringent requirements of the market for products, jwell has developed advanced five-layer symmetric and seven-layer asymmetric distribution technology to carry out multi-machine co-extrusion of three machines or five machines according to the customer's requirements for products, so that the products produced by the equipment have better versatility, which is of great help in functionality and cost control.

Film Extrusion DieFilm Extrusion Die

Jwell company has its own core parts processing workshop. The film mold has a series of products such as high-speed film coating die, film die, biaxial tensile die, narrow seam coating die, and so on.

Highlights of Film Extrusion Line

1

The plastic film extrusion production line has the following characteristics: the flat plastic film extrusion process is continuous, and its products are also continuous; High production efficiency; Wide application r...

2

Jwell's plastic film extrusion production line is multifunctional and has high flexibility. There is a multi-layer distribution coextrusion production line, which can mix materials with different ...

3

The core part of the plastic film extrusion production line of jwell company is independently designed and manufactured. Jwell company has its own processing workshop, which makes different extrusion ...

4

The plastic film extrusion production line of jwell extrusion machinerycan adopt the one-step tape casting compound mode. The production line has the function of high-speed automation to realize the single-sided...

Products

FAQ about Film Extrusion Line

In Film cast extrusion, is there any relationship between die width and thickness of the film?

In the process of film extrusion molding, the width of the film has the most direct relationship with the width of the die. In the process of back molding, the shrinkage of different materials may also have a certain impact on the width of the film, but the most direct factor of the film width depends on the width of the die.

What are the applications of Film Extrusion Line?

Main Process of Film Extrusion Line

The production process of the film extrusion production line is as follows:

Prepare raw materials - raw materials enter the feeding machine, enter the main machine hopper through the feeding machine - feed by the extruder, mix through the screw, shear and plasticize - extrude the plasticized materials through the screw, filter impurities through the flow channel, or conduct secondary plasticization through the metering pump - after passing through the flow channel, the plasticized and filtered materials enter the mold for forming - after the mold is formed, the raw materials enter the three roller press, Adjust the thickness and control the width after stretching - press and enter the cooling support for cooling and forming - then pull back by the tractor - the finished product winder rolls up the final finished product after complete cooling.

Now we have high quality film extruderfor sale, if you want to buy film extruder, please contact us.

Send product request

Other supplier products

| PVC Twin Screw Extruder | PVC Twin Screw Extruder PVC is a non-crystalline polymer of polyvinyl chloride. Its glass transition temperature is 105℃-75℃ depending on the mo... | |

| Multilayer Extruder Machine | Multilayer Extruder Machine Due to the increasingly stringent requirements of the market for products, Jwell extrusion machineryhas developed ad... | |

| PP Blow Moulding Machine | PPblow moulding machineis a product formed by a rapidly developing plastic processing method. Use PP plastic to extrude one-time blow molding. Duri... | |

| HDPE Pipe Extrusion Machine | HDPEextrusion machineproduction line adopts the most advanced technology of Europe, It is a new research achievement of energy-saving production li... | |

| Multilayer Extruder Machine | Due to the increasingly stringent requirements of the market for products, Jwell extrusionhas developed advanced five-layer symmetric and seven-lay... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |