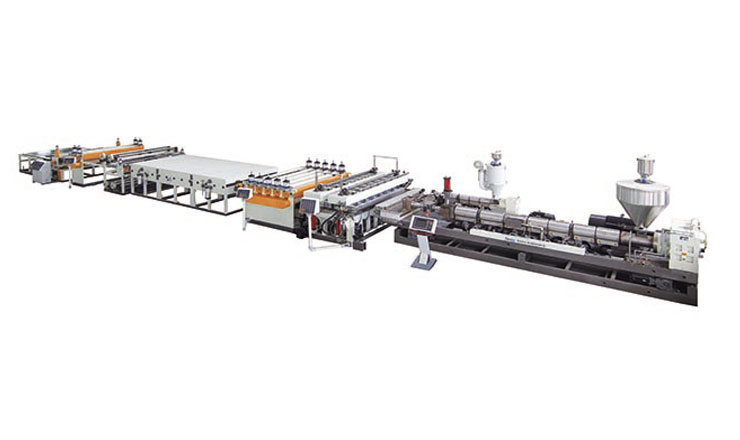

PC Sheet Extrusion Line

Jwell's PC Sheet Extrusion Line, PMMA Sheet Extrusion Lineis mainly divided into the following types:

Application scope of PC endurance board: gardens, exotic decorations in entertainment places and corridors and pavilions in rest places; Interior and exterior decorations of commercial buildings and curtain walls of modern urban buildings; Transparent aviation containers, front windshields of motorcycles, aircraft, trains, ships, automobiles, steamships, submarines and glass military and police shields; Layout of tele booths, advertising signboards, light boxes, advertising exhibitions; Noise barriers for expressways and urban viaducts.

PMMA plate produced by PMMA Sheet Extrusion Line(acrylic plate / GPPS plate)

Product classification: ordinary PMMA plate is mainly used for advertising, decoration, decoration, craft products, specimen signs, etc; Electroplating plate is used for vacuum electroplating plastic lens; Lighting light guide plate is used for advertising decoration such as ultra-thin light box, LED flat panel display lamp and poster frame; Liquid crystal light guide plate is used for computer, TV and other liquid crystal display components. The plate extrusion line provided by jwell plastic extrusion companycan be used to process PMMA or PC diffusion plates.

Description About PC Sheet Extrusion Line

Specifications of PC Sheet Extrusion Line

PC Sheet Extrusion Line Application

PC sheet has high strength, elastic coefficient, high impact strength, and wide temperature range; High transparency and free dyeing; Low forming shrinkage and good dimensional stability; Good fatigue resistance; Good weather resistance; Excellent electrical characteristics; It has the advantages of good impact resistance and transparency, no deformation and transparency when washing with hot water and corrosive solution. It is widely used in daily life, especially in industry.

PC materials can be applied in the following aspects:

FAQ about PC Sheet Extrusion Line

Can your production line use more than one machine?+

Due to the similar characteristics of some materials, jwell's sheet production line can produce several products of different materials with one machine. For example, the PC sheet extrusion production line provided by jwell can be used to process PMMA or PC diffusion plate, and jwell's pet sheet extrusion line can be used to produce pet and PLA packaging sheets.

How long is the delivery date?+

How long is the warranty period?+

PC Sheet Extrusion Line Performance and Advantages

In order to meet the needs of the market, jwell machinery china company provides users with an optical grade sheet production line with advanced technology and equipment. The special screw and precise metering pump system and die designed according to the rheology of raw materials ensure the uniformity and stability of melt and excellent optical properties of sheet; The precise calendering system guarantees the mechanical and physical properties of the sheet. The screw of PC optical sheet production line adopts special mixing and high plasticizing capacity design to greatly reduce the generation of crystal point. The hanger die adopts special double section design with coarse adjustment and fine adjustment to make the sheet thickness adjustment more accurate. Different types of three roller calenders are selected for plates of different materials to improve the production process.

PC sheet produced by PC Sheet Extrusion Line is mainly used in: automotive industry, electronics, electrical industry, LCD and industrial machinery parts, plated mirrors, various signs, printing, film switches, nameplate, and protective mask. It can be used in thick film blister machine for Blister processing, making various PC lampshades, PC signs, protective covers, vending machine panels, daylighting covers, etc.

If you want to know more information about pp hollow sheet extrusion line, please visit our website.

Send product request

Other supplier products

| PS Sheet Extrusion Line | The PS sheet production line of JWELLmachineryis divided into: GPPS plate production line: ordinary GPPS plate is mainly used for advertisin... | |

| Sheet Extrusion Line | Sheet extrusion line refers to the production equipment which is used to heat the plastic raw materials (particles) in the plastic extruder, melt t... | |

| PP Hollow Sheet Extrusion Line | Jwell hollow plates are as follows: PP Hollow Building Formwork Double Out Extrusion Line: PP hollow building template the first mock exam do... | |

| Film Extrusion Line | Film extrusion lineis a kind of screw plastic film extruder. The working mechanism of screw plastic extruder is to fully plasticize the materials b... | |

| HDPE Pipe Extrusion Machine | HDPEextrusion machineproduction line adopts the most advanced technology of Europe, It is a new research achievement of energy-saving production li... |

Same products

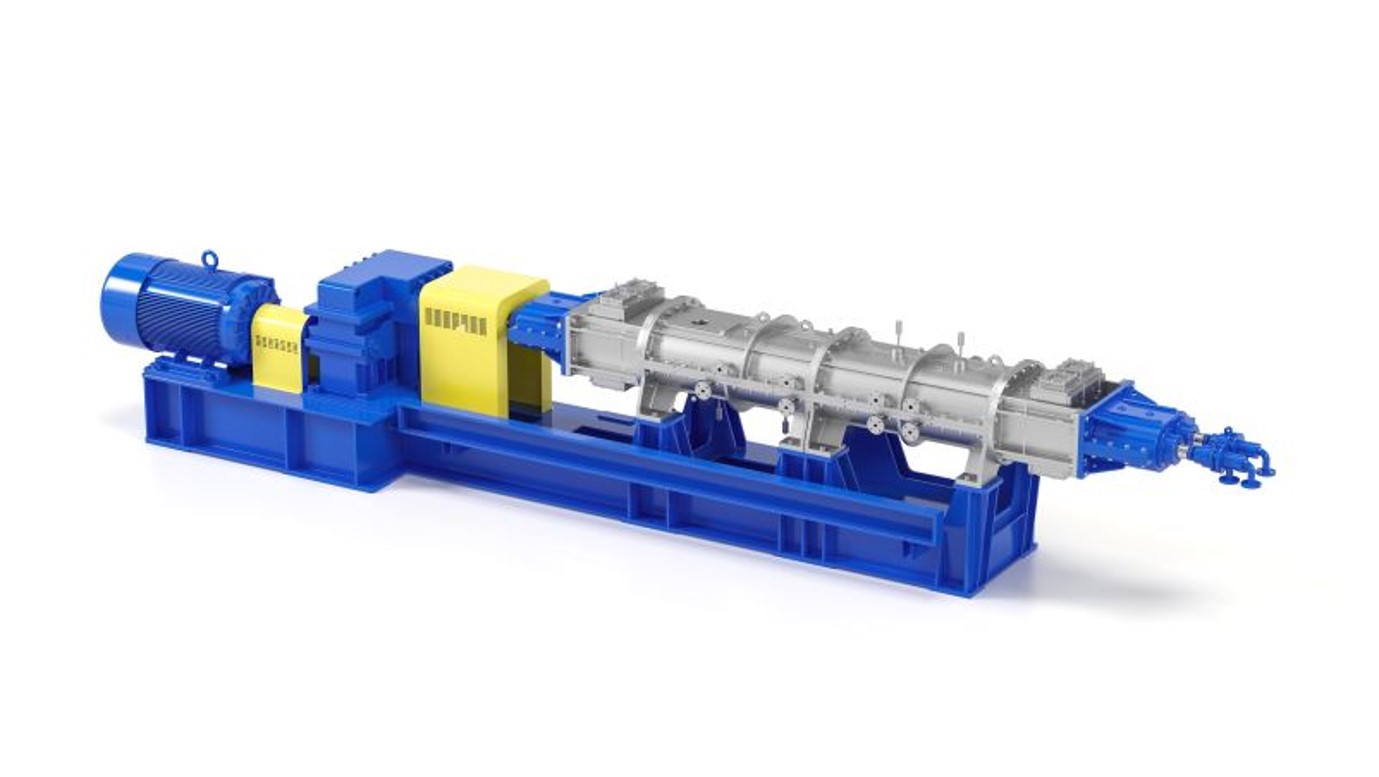

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... | |

| SUNKAIER SK3000S-EXTRUDING KNEADER REACTOR | Seller: Jiangsu Sunkaier Industrial Technology Co., Ltd. | SUNKAIER SK3000S-EXTRUDING KNEADER REACTOR DESCRIPTION SK3000S Kneader is ideally suited fo... | |

| PVC WPC Panel Board Extrusion Line | Seller: JWELL MACHINERY(CHANGZHOU)CO., LTD | Jwell extrusion has specialized in plastic extrusion machines and complete solutions for over 25 ... | |

| PVC Window Profile Extrusion Line | Seller: JWELL MACHINERY(CHANGZHOU)CO., LTD | Our high quality PVC window profile extrusion line equipped with special conical twin screw extru... |