Automatic Drying And Feeding Machine

Hopper dryer is the replacement product of standard hot air dryer, which is improved on the basis of the original function to fully consider the environmental factors. It can dry raw materials that are moist from packaging, transportation or recycling.

In the processing of raw materials, the hopper dryer blows a constant high-temperature wind into the drying barrel through a drying fan. After baking the raw materials, the original moisture of the raw materials in the barrel is taken away so as to achieve the purpose of removing the moisture contained in the raw materials. After heating by electric heating, the air blown out by the fan becomes a high-temperature dry hot air. Through the screen protector and hole screen, the hot air can be evenly dispersed into the raw materials in the drying drum. Optional hot-air recovery device, the air is blown out through the return air filter into the drying fan to form a closed loop to save electricity.

Features of Automatic Plastic ExtrusionDryingAnd Feeding Machine

The high-performance hot air diffuser is adapted to keep the plastic drying temperature even and increase drying efficiency.

The special design of hot air elbow can avoid powder accumulation at the bottom of the electric heat pipe and cause combustion.

The inner and inner parts of the barrel shall be made of stainless steel.

The material bucket is separated from the bottom, making it easy to clear the material and quick to replace it.

The temperature can be controlled accurately by means of proportional deviation indicating controller.

Double overheat protection to reduce accidents caused by man-made or mechanical failure.

All kinds of models can provide preheating timing device, microcomputer control, and double insulation drum selection.

It will start automatically when hours are set.

Provide intermittent drying mode to achieve the purpose of saving electricity.

Transparent window type magnet base.

Qingdao Kailiteplastic machinery Co., LTD. is a extrusion line manufacturer, we provide plastic production line, plastic extrusion line, plastic extruder net machineand etc. Want to know more, contact us.

Send product request

Other supplier products

| SJSZ Conical Twin Screw Extruder | Main technique parameter ( conical twin screw ) Model ltem SJSZ- 45*22 SJSZ- 50*22 SJSZ- 55*22 SJSZ- 60*22 SJSZ- 65*22 SJSZ- 80*22... | |

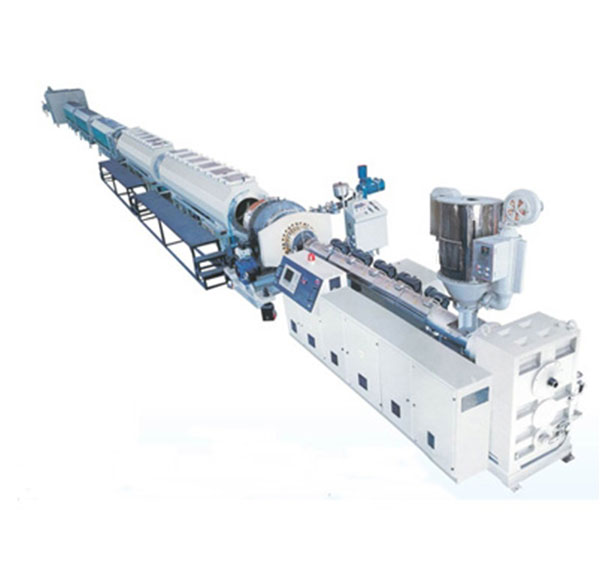

| PP-R/PP/PE Plastic Tube Production Line | That production line design special, adoption BM separate type efficiently the pole of automating the degree is high, operation convenience, contin... | |

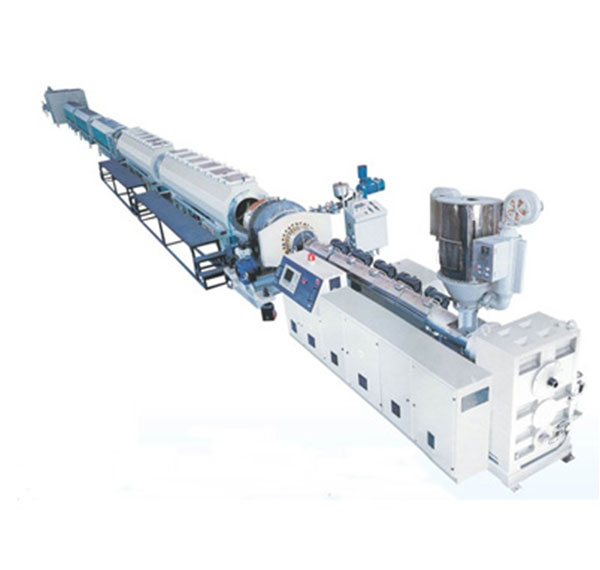

| PP-R/PP/PE Plastic Tube Production Line | That production line design special, adoption BM separate type efficiently the pole of automating the degree is high, operation convenience, contin... | |

| WPC Extrusion Production Equipment | In recent years, wood-plastic products have become popular materials for ordinary household decoration and municipal construction projects. On the ... | |

| Plastic Extruder Machine Manufacturer | Are you still troubled because you can't find a suitable extruder linemanufacturer? KailitePlastic Machinery is the one-stop supplier you need! For... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |