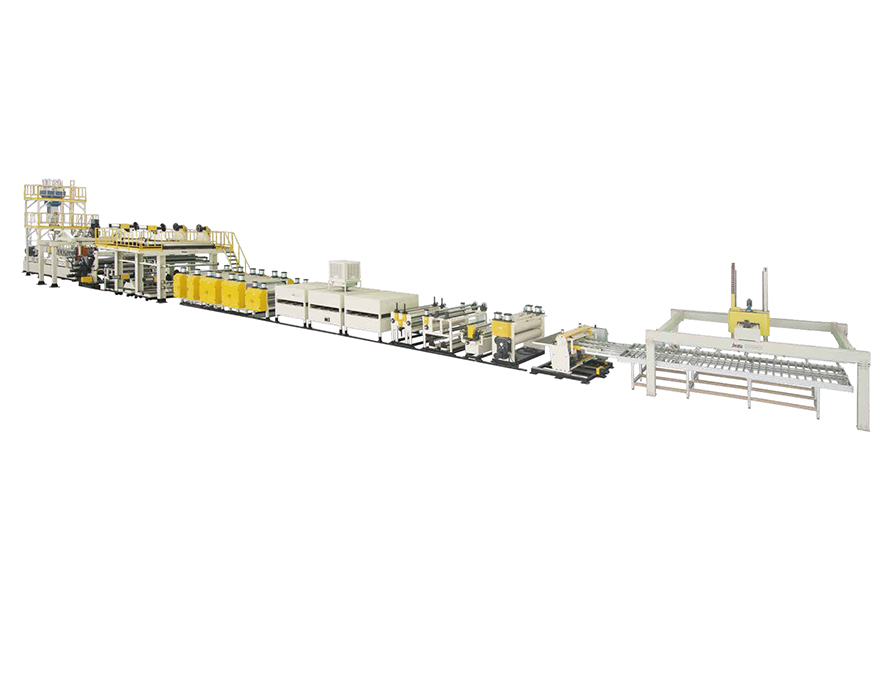

Aluminum Plastic Composite Plate Extrusion Line

Our company JWELL has ranked first in the extrusion industry for 12 consecutive years, making us one of the leaders in China's extrusion machinery industry. With over 25-years experience of export and manufacture, we’re professional at aluminum plastic composite plate extrusion line and complete technical solutions. Our JWS180 single-screw extruder can reach 800kg/h, conical twin-screw extruder can reach 1400kg/h, parallel twin-screw can reach 2500kg/h.

The final aluminum plastic composite panel produced by our production line can meet the market standard and has the features of smooth surface, uniform thickness, wear resistance, corrosion resistance, anti-static and fire protection (According to the characteristics of different raw materials, the fire rating is different).

Advantages of JWELL Aluminum Plastic Composite Plate Extrusion Line

The Structure of Aluminum Plastic Composite Panel (7 Layers)

Core layer: The main raw material is low-density polyethylene (LDPE), and a small amount of linear low-density polyethylene (LLDPE) will be added to improve flexibility and impact resistance; Flame retardant will be added for those with high requirements to make products fireproof and flame retardant.

Polymer adhesive film: The function of the adhesive film is to bond the aluminum foil and polyethylene core layer after being heated. The main raw materials are LLDPE and EVA or POE mixture. The thickness of adhesive film is generally 0.045mm, 0.05mm, 0.1mm.

Aluminum foil: Customers order aluminum foil with surface treatment according to product use, and the general thickness range is 0.06-0.5mm.

Protective film: It is mainly made of polyethylene and easy to peel, which can protect the surface of aluminum plastic plate from pollution, corrosion and scratch during transportation, storage and use, and protect the original smooth and bright surface, so as to improve the product quality and market competitiveness. The thickness range available in general market is 0.03-0.15mm.

Complete production process: Automatic drying feeder, JWS90/38 single screw extruder, Metering pump, Mold, Vacuum calibration table, Haul off machine, Chipless cutting, PLC control system.

Applications of Aluminum plastic composite panel extrusion line

Aluminum plastic composite plate has the characteristics of beauty, durability, light weight, high strength, good temperature adaptability, good fire resistance, strong acid resistance, good sound insulation, easy maintenance, simple cleaning, etc. It is also a very popular new interior and exterior wall decoration material in recent years because of its low cost and good decoration effect.

Due to many advantages in material performance, aluminum plastic panels are widely used in various architectural decoration, such as ceilings, wrapped columns, counters, furniture, tele booths, elevators, storefronts, billboards, dust-proof room walls, factory walls, etc. In developed countries, aluminum plastic panels are also used in the manufacture of bus and train boxes, aircraft Compartment wall materials, equipment, external boxes of instruments, etc.

For more information about plastic pipe extruder, please feel free to contact us!

Send product request

Other supplier products

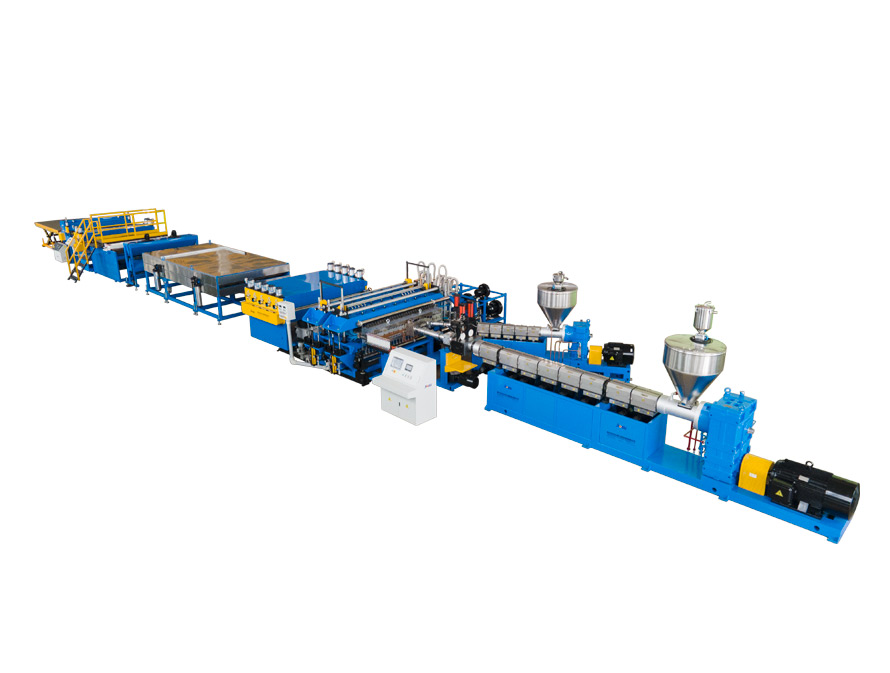

| TPO PVC EVA HDPE Waterproof Geomembrane Sheet Extrusion Line | With over 25 years experience and have ranked No.1 in the plastic extrusion industry for 11 consecutive years, accumulating rich manufacturing expe... | |

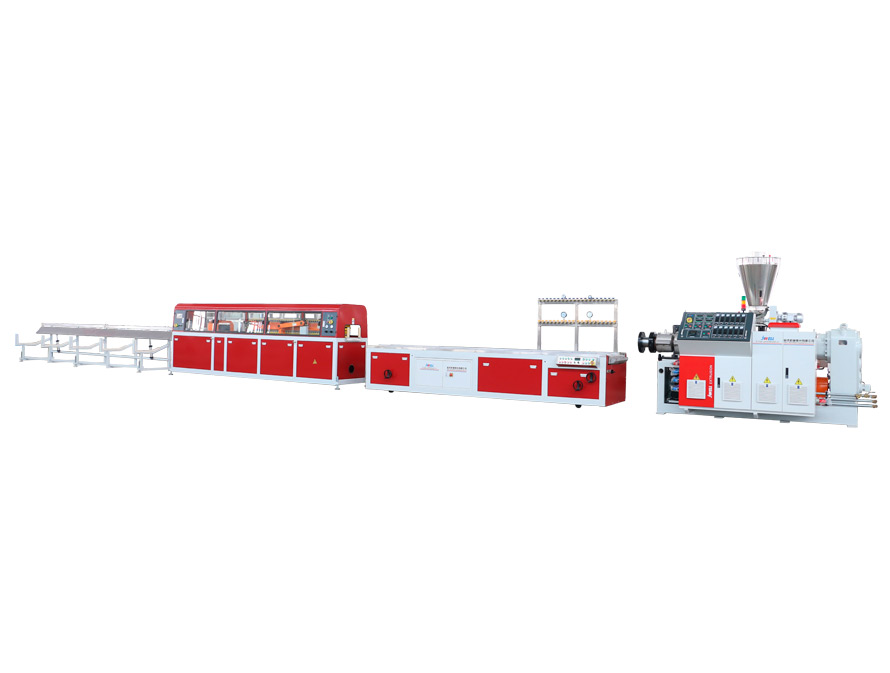

| PVC Ceiling Panel Extrusion Line | We've focused on providing good quality PVC ceiling panel extrusion linefor over 25 years since 1997, and have accumulated rich experience and matu... | |

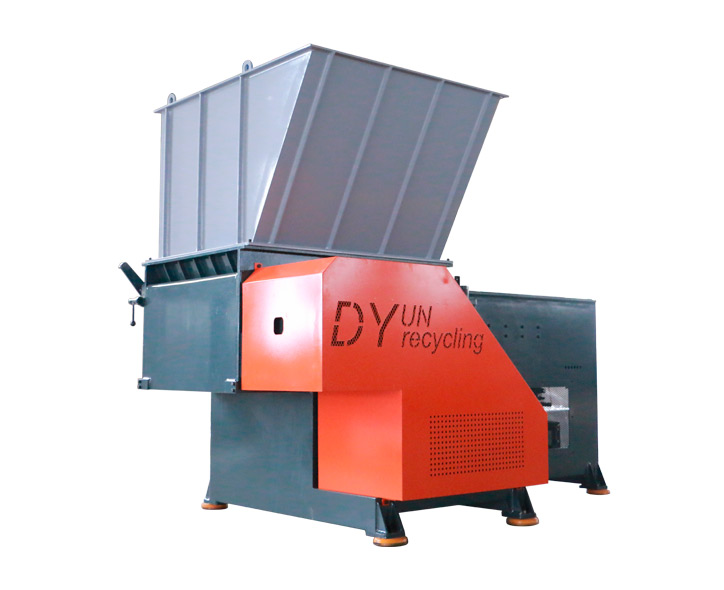

| Recycling Line | Our main products of china plastic recycling machine include material weighing and mixing automation system, plastic crusher, single shaft shredder... | |

| PC PP PE Plastic Hollow Sheet Extrusion Line | We're professional plastic china pc sheet extrusion linemanufacturer with over 25 years' technical R&D experience and the technology leader in ... | |

| Profile Extrusion Line | We have specialized in various plastic profile extrusion production lines for over 25 years and accumulated rich experience of export and extrusion... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |