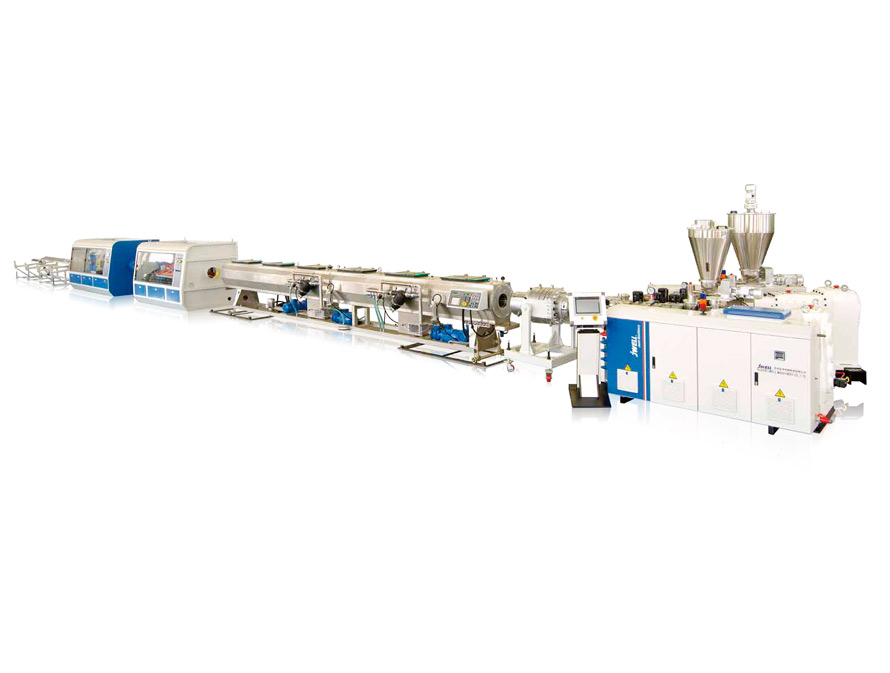

Fiber Glass PPR Pipe Co-extrusion Line

The production process of PPR fiberglass pipe is to immerse the glass fiber into resin and be formed in the high-speed polymerization device integrating light and electricity, through co-extrusion, the inside and outside layers are coated with Polypropylene material. We have rich exporting and manufacturing experience of.

The technical parameters of the PPR glass fiber pipe extrusion line independently researched and developed by our company Jwell are better than those of similar domestic equipment, and some performance indexes even exceed those of similar European equipment.

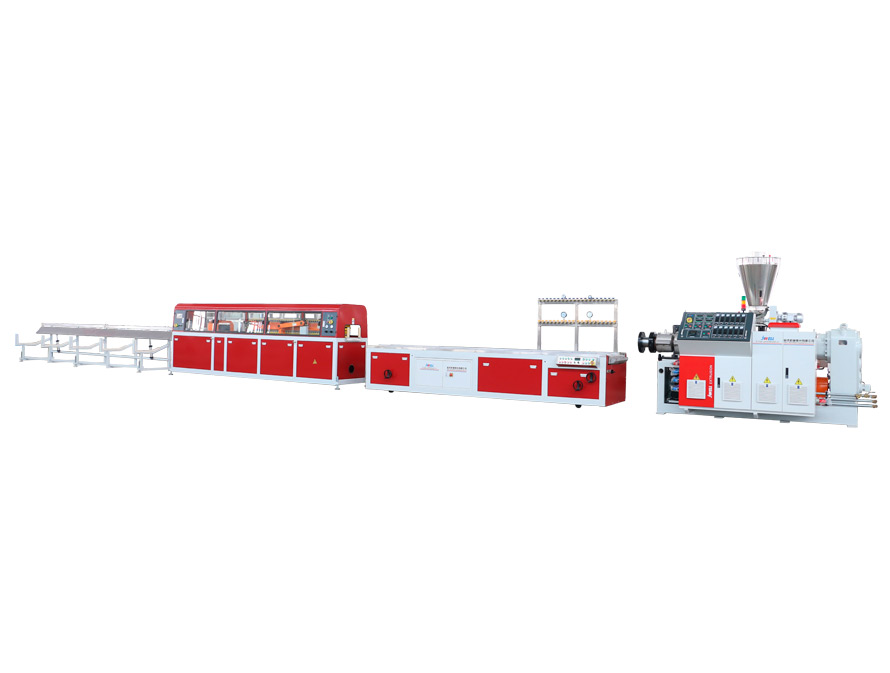

Because of its unique performance advantages of higher pressure and temperature resistance, long service life, high strength and impact resistance, PPR glass fiber pipes have been widely used in many industries, such as aerospace, railway, decorative architecture, home furniture, advertising display, craft gifts, building materials and sanitary ware, yacht berthing, sports materials, environmental sanitation engineering, and so on.

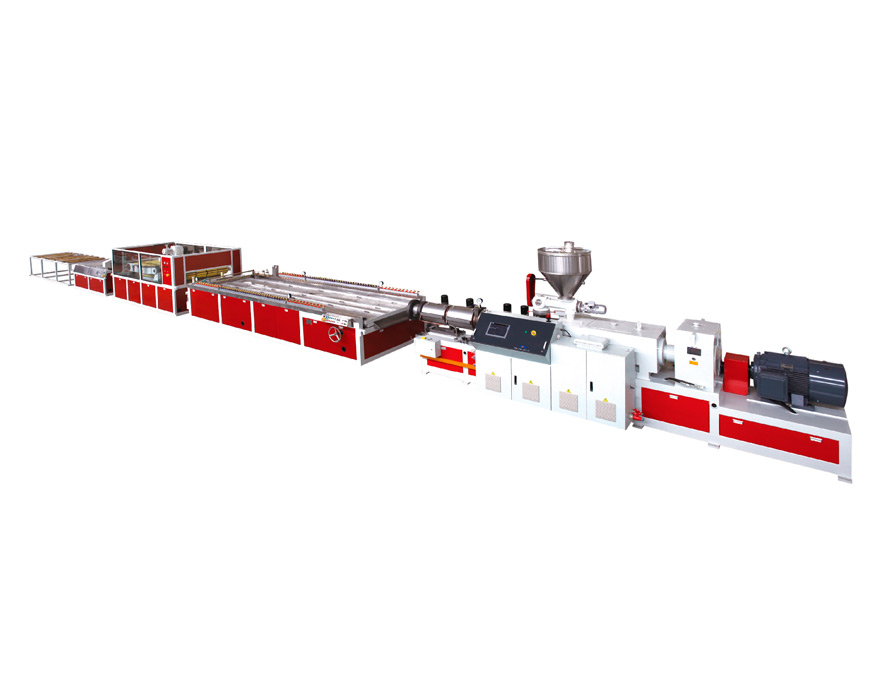

Advantages of Fiber Glass ppr pipe production line

Intelligent SIEMENS PLC control system, easy operation.

The transmission system has the characteristics of high precision, low noise and long service life.

The internal flow channel of pipe mould has been chrome plated and polished to keep high quality pipes.

Professional pressure and temperature control technology.

Jwell has over 3000 staff, including experienced technology engineers and professional operators, which means we can be your reliable partner.

The Application of Fiber Glass PPR Pipe Co-extrusion Line

With its unique advantages, PPR glass fiber pipe has been widely used in petroleum, electric power, chemical industry, new energy, urban water supply and drainage, factory sewage treatment, seawater desalination, gas transmission and other industries.

For more information about pvc pipe extruder, please feel free to contact us!

Send product request

Other supplier products

| PVC Fence Panel Extrusion Line | This PVC fence panel making machineadopts our professional developed SJZ92/188 conical twin screw extruderwith the advantages of excellent plastici... | |

| Extruder Screw & Barrel | All screws and barrels of our extrusion lines are produced by our own professional extruder screw barrel factory, called Zhoushan Jwell Screw&b... | |

| PVC WPC Panel Board Extrusion Line | Jwell extrusion has specialized in plastic extrusion machines and complete solutions for over 25 years, also have ranked No.1 in the extrusion indu... | |

| PVC Ceiling Panel Extrusion Line | We've focused on providing good quality PVC ceiling panel extrusion linefor over 25 years since 1997, and have accumulated rich experience and matu... | |

| PP Hollow Building Template Extrusion Line | We're professional extruder machine for plasticmanufacturer with over 25 years' technical R&D experience and the technology leader in extrusion... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |