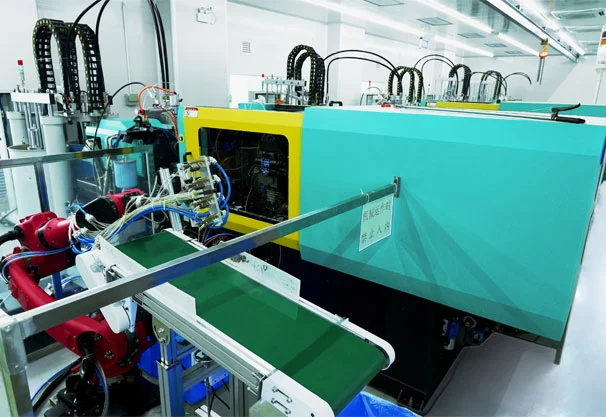

thermosetting injetion molding machine DK-2100S

· DK Series

· Vertical type four column clamping, horizontal injection, convenient to put and take out the items.

· Strong mechanical structure, high pressure, high speed, fit for large inserts plastic product molding.

· Optional: , increase production efficiency and safety of the operators.

· Humanization design of the height of the work plate and slide table, rotary table, let the mold install and unload more conveniently, increase production efficiency effectively.We are .

|

Specification |

|||||

|

Model |

Unit |

DK-1600S |

|||

|

(Injection Unit) |

Screw diameter |

mm |

Ф45 |

Ф50 |

Ф55 |

|

Maximum injection pressure |

Kg/cm2 |

2291 |

1856 |

1534 |

|

|

Theoretical shot volume |

cm3 |

381 |

471 |

570 |

|

|

Maximum shot weight |

g/Oz |

340(11.9) |

420(14.8) |

509(17.9) |

|

|

Injection rate |

cm3/sec |

127 |

157 |

190 |

|

|

(Clamping Unit) |

Clamping force |

ton |

160 |

||

|

Sliding Table size |

mm |

440 × 700 |

|||

|

Sliding Table Stroke |

mm |

700 |

|||

|

tie bar distance |

mm |

460× 600 |

|||

|

Minimum mold thickness |

mm |

250(Can be customized according to customer requirements) |

|||

|

Opening stroke |

mm |

350 |

|||

|

Open daylight |

mm |

600(As required) |

|||

|

Nozzle Center Height |

mm |

175±20 |

|||

|

Nozzle Center Distance |

mm |

125 |

|||

|

Ejector force |

T |

|

|||

|

Ejector stroke |

mm |

75 |

|||

|

(Others) |

Pump motor power |

Kw |

|||

|

Hydraulic system pressure |

Kg/cm2 |

140 |

|||

|

Barrel heating power |

Kw |

||||

|

Total wattage |

Kw |

||||

|

Oiltank capacity |

L |

500 |

|||

|

Machine weight (approx.) |

T |

||||

|

Machine dimensions(approx.) |

m |

||||

|

Specificationof |

|||||

|

Model |

Unit |

DK-2100S |

|||

|

(Injection Unit) |

Screw diameter |

mm |

Ф50 |

Ф55 |

Ф60 |

|

Maximum injection pressure |

Kg/cm2 |

2288 |

1891 |

1589 |

|

|

Theoretical shot volume |

cm3 |

491 |

594 |

707 |

|

|

Maximum shot weight |

g/Oz |

490(16) |

593(19.4) |

706(23) |

|

|

Injection rate |

cm3/sec |

127 |

154 |

183 |

|

|

(Clamping Unit) |

Clamping force |

ton |

210 |

||

|

Sliding Table size |

mm |

540× 800 |

|||

|

Sliding Table Stroke |

mm |

750 |

|||

|

tie bar distance |

mm |

560× 700 |

|||

|

Minimum mold thickness |

mm |

300(Can be customized according to customer requirements) |

|||

|

Opening stroke |

mm |

400 |

|||

|

Open daylight |

mm |

700(As required) |

|||

|

Nozzle Center Height |

mm |

175±20 |

|||

|

Nozzle Center Distance |

mm |

150 |

|||

|

Ejector force |

T |

|

|||

|

Ejector stroke |

mm |

120 |

|||

|

(Others) |

Pump motor power |

Kw |

22 |

||

|

Hydraulic system pressure |

Kg/cm2 |

140 |

|||

|

Barrel heating power |

Kw |

12 |

|||

|

Total wattage |

Kw |

34 |

|||

|

Oiltank capacity |

L |

550 |

|||

|

Machine weight (approx.) |

T |

||||

|

Machine dimensions(approx.) |

m |

||||

|

Specification |

|||||

|

Model |

Unit |

DK-2500S |

|||

|

(Injection Unit) |

Screw diameter |

mm |

Ф50 |

Ф55 |

Ф60 |

|

Maximum injection pressure |

Kg/cm2 |

2288 |

1891 |

1589 |

|

|

Theoretical shot volume |

cm3 |

491 |

594 |

707 |

|

|

Maximum shot weight |

g/Oz |

490(16) |

593(19.4) |

706(23) |

|

|

Injection rate |

cm3/sec |

127 |

154 |

183 |

|

|

(Clamping Unit) |

Clamping force |

ton |

250 |

||

|

Sliding Table size |

mm |

580×850 |

|||

|

Sliding Table Stroke |

mm |

800 |

|||

|

tie bar distance |

mm |

600× 735 |

|||

|

Minimum mold thickness |

mm |

300(Can be customized according to customer requirements) |

|||

|

Opening stroke |

mm |

450 |

|||

|

Open daylight |

mm |

750(As required) |

|||

|

Nozzle Center Height |

mm |

175±20 |

|||

|

Nozzle Center Distance |

mm |

150 |

|||

|

Ejector force |

T |

|

|||

|

Ejector stroke |

mm |

120 |

|||

|

(Others) |

Pump motor power |

Kw |

30 |

||

|

Hydraulic system pressure |

Kg/cm2 |

140 |

|||

|

Barrel heating power |

Kw |

12 |

|||

|

Total wattage |

Kw |

42 |

|||

|

Oiltank capacity |

L |

600 |

|||

|

Machine weight (approx.) |

T |

21 |

|||

|

Machine dimensions(approx.) |

m |

||||

|

Specification |

|||||

|

Model |

Unit |

DK-3000S |

|||

|

(Injection Unit) |

Screw diameter |

mm |

Ф55 |

Ф60 |

Ф65 |

|

Maximum injection pressure |

Kg/cm2 |

2036 |

1711 |

1458 |

|

|

Theoretical shot volume |

cm3 |

618 |

735 |

863 |

|

|

Maximum shot weight |

g/Oz |

571(20.1) |

679(24) |

797(28.1) |

|

|

Injection rate |

cm3/sec |

207 |

246 |

289 |

|

|

(Clamping Unit) |

Clamping force |

ton |

300 |

||

|

Sliding Table size |

mm |

600× 950 |

|||

|

Sliding Table Stroke |

mm |

900 |

|||

|

tie bar distance |

mm |

620× 780 |

|||

|

Minimum mold thickness |

mm |

300(Can be customized according to customer requirements) |

|||

|

Opening stroke |

mm |

450 |

|||

|

Open daylight |

mm |

750(As required) |

|||

|

Nozzle Center Height |

mm |

175±20 |

|||

|

Nozzle Center Distance |

mm |

150 |

|||

|

Ejector force |

T |

|

|||

|

Ejector stroke |

mm |

120 |

|||

|

(Others) |

Pump motor power |

Kw |

30 |

||

|

Hydraulic system pressure |

Kg/cm2 |

140 |

|||

|

Barrel heating power |

Kw |

||||

|

Total wattage |

Kw |

||||

|

Oiltank capacity |

L |

700 |

|||

|

Machine weight (approx.) |

T |

||||

|

Machine dimensions(approx.) |

m |

||||

|

Specification |

|||||

|

Model |

Unit |

DK-3500S |

|||

|

(Injection Unit) |

Screw diameter |

mm |

Ф60 |

Ф65 |

Ф70 |

|

Maximum injection pressure |

Kg/cm2 |

1866 |

1590 |

1370 |

|

|

Theoretical shot volume |

cm3 |

791 |

928 |

1077 |

|

|

Maximum shot weight |

g/Oz |

705(24.8) |

829(29.2) |

961(33.8) |

|

|

Injection rate |

cm3/sec |

158 |

186 |

215 |

|

|

(Clamping Unit) |

Clamping force |

ton |

350 |

||

|

Sliding Table size |

mm |

620× 1050 |

|||

|

Sliding Table Stroke |

mm |

1050 |

|||

|

tie bar distance |

mm |

650×830 |

|||

|

Minimum mold thickness |

mm |

300(Can be customized according to customer requirements) |

|||

|

Opening stroke |

mm |

450 |

|||

|

Open daylight |

mm |

750(As required) |

|||

|

Nozzle Center Height |

mm |

200±20 |

|||

|

Nozzle Center Distance |

mm |

150 |

|||

|

Ejector force |

T |

|

|||

|

Ejector stroke |

mm |

120 |

|||

|

(Others) |

Pump motor power |

Kw |

37 |

||

|

Hydraulic system pressure |

Kg/cm2 |

140 |

|||

|

Barrel heating power |

Kw |

||||

|

Total wattage |

Kw |

||||

|

Oiltank capacity |

L |

800 |

|||

|

Machine weight (approx.) |

T |

25 |

|||

|

Machine dimensions(approx.) |

m |

||||

|

Specification |

|||||

|

Model |

Unit |

DK-4500S |

|||

|

(Injection Unit) |

Screw diameter |

mm |

Ф65 |

Ф70 |

Ф75 |

|

Maximum injection pressure |

Kg/cm2 |

1968 |

1697 |

1478 |

|

|

Theoretical shot volume |

cm3 |

1062 |

1232 |

1414 |

|

|

Maximum shot weight |

g/Oz |

948(33.4) |

1099(38.8) |

1262(44.5) |

|

|

Injection rate |

cm3/sec |

289 |

335 |

385 |

|

|

(Clamping Unit) |

Clamping force |

ton |

450 |

||

|

Sliding Table size |

mm |

650×1050 |

|||

|

Sliding Table Stroke |

mm |

1050 |

|||

|

tie bar distance |

mm |

680×900 |

|||

|

Minimum mold thickness |

mm |

350(Can be customized according to customer requirements) |

|||

|

Opening stroke |

mm |

600 |

|||

|

Open daylight |

mm |

950(As required) |

|||

|

Nozzle Center Height |

mm |

200±20 |

|||

|

Nozzle Center Distance |

mm |

200 |

|||

|

Ejector force |

T |

7(Can be customized according to customer requirements) |

|||

|

Ejector stroke |

mm |

150 |

|||

|

(Others) |

Pump motor power |

Kw |

41 |

||

|

Hydraulic system pressure |

Kg/cm2 |

140 |

|||

|

Barrel heating power |

Kw |

||||

|

Total wattage |

Kw |

||||

|

Oiltank capacity |

L |

900 |

|||

|

Machine weight (approx.) |

T |

34 |

|||

|

Machine dimensions(approx.) |

m |

||||

|

Specification |

|||||

|

Model |

Unit |

DK-5500S |

|||

|

(Injection Unit) |

Screw diameter |

mm |

Ф70 |

Ф75 |

Ф80 |

|

Maximum injection pressure |

Kg/cm2 |

2057 |

1792 |

1575 |

|

|

Theoretical shot volume |

cm3 |

1847 |

2121 |

2413 |

|

|

Maximum shot weight |

g/Oz |

1648(58) |

1893(66.8) |

2153(76) |

|

|

njection rate |

cm3/sec |

323 |

371 |

422 |

|

|

(Clamping Unit) |

Clamping force |

ton |

550 |

||

|

Sliding Table size |

mm |

720×1200 |

|||

|

Sliding Table Stroke |

mm |

1200 |

|||

|

tie bar distance |

mm |

750×1000 |

|||

|

Minimum mold thickness |

mm |

450(Can be customized according to customer requirements) |

|||

|

Opening stroke |

mm |

600 |

|||

|

Open daylight |

mm |

950(As required) |

|||

|

Nozzle Center Height |

mm |

200±20 |

|||

|

Nozzle Center Distance |

mm |

200 |

|||

|

Ejector force |

T |

7(Can be customized according to customer requirements) |

|||

|

Ejector stroke |

mm |

150 |

|||

|

(Others) |

Pump motor power |

Kw |

48 |

||

|

Hydraulic system pressure |

Kg/cm2 |

140 |

|||

|

Barrel heating power |

Kw |

22 |

|||

|

Total wattage |

Kw |

70 |

|||

|

Oiltank capacity |

L |

1000 |

|||

|

Machine weight (approx.) |

T |

34 |

|||

|

Machine dimensions(approx.) |

m |

||||

More information please click .

Send product request

Other supplier products

| liquid silicone rubber injection molding machine DV-850.3R.CE | All models ofare manufactured in strict accordance with the EU machinery industry standards, fully in line with the EU CE standards, and have pass... | |

| hybrid vertical injection molding machine DV-1600S | If You Have Any Question On Hybrid Vertical Injection Moulding Machine, , We Will Give The Professional Answers To Your Short Questions. Single... | |

| tube shoulder making machine DV-600DS | We Provide Tube Shoulder Making Machine And High Quality, If You Need, Welcome To Contact Us To . Double Slide Table Style of DV-DS Series *Verti... | |

| high speed injection molding machine DV-600.CE | The CE series : approved by the European Union, equipment collection area is designed with ergonomic design. The safety protection devices in all... | |

| rotary table injection molding machine DC-450.2R | ·Clamping force : 45Ton-120Ton ·Injection weight : 97-415g ·Vertical clamping and horizontal injection design ·Rigid C... |

Same products

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| Silicone Rubber Injection Molding | Seller: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | Seller: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | Seller: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | Seller: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... |