Explore Packson's Injection Molding Services

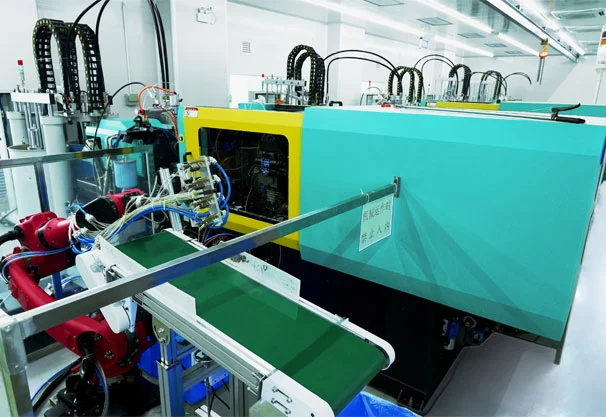

With more than 20 years experience of injection molding industry and equipped with ISO Class 8 Clean Room, as the injection moulding suppliers, we offer Medical Contract Plastic & Rubber Injection Molding, Custom Injection Molding, and Over Molding by more than 40 injection machines that range from 60 to 1000 tons of clamping pressure and are keep growing every day.

Packson is an ISO 13485 and ISO 9001 certified medical injection moulding company. As our competition in the injection molding industry is far ahead, being a cutting-edge China injection moulding company, we specialize in plastic injection molding and contract manufacturing for OEMs like BD, Lear, and Wondfo. Except for Medical, we also provide injection molding services for different industries including Automotive, Airplane Components, Electronic Products, Consumer Products, Packaging, Toys, Construction, and Agriculture.

Not all customers will place an order of a million parts to get started. We are able to produce customized injection molding in chinaqty according to your personal solution and fulfill your needs. We will check color, appearance, and tolerance by quality control at every step during the injection molding manufacturing process.

Our China injection molding company's great efficiency and good control that converts into a better quality product with a more competitive injection molding price by investment in equipment and QC system. This is also the most important factor that we can provide good quality injection molding parts on time.

Types of Injection Moulding Service Available

Medical Injection Molding

Packson passed the ISO13485 certification and established an ISO class 8 dust-free injection molding production workshop.

Clean Room Injection

Medical Liquid Silicone Rubber(LSR) molding is also one of our important buisness.Packson built class 8 clean room for LSR moldingand ship out 20K pcs parts every week.

Plastic Injection Molding

With more than 40 injection machines from 10 tons to 1000 tons, we have ability to help you make all kinds of parts and meet different needs.

Silicone Rubber Injection Molding

Liquid Silicone Rubber Molding is becoming more and more popular for medical and food industry. We have normal injection room and clean room for meeting your various needs.

Custom Contract Molding

Not all custom contract molding provider are the same. We are an ISO-certified who provide engineering, custom injection molding, and contract manufacturing services.

Injection Molding Process

What is injection Molding

Injection molding is the process of obtaining moulded products via injecting heat-molten plastics into a mould. Then cooling parts down and solidifying them in the cavity. The way is applied for the high volume of products with complex forms and is largely involved in the field of plastic industry. The injection moulding method consists of 6 main steps as follows. The method is carried out as described above and the products are carried out in succession by repetition of the run.

How does injection molding work?

The injection molding process consists of six steps: 1. Clamping 2. Injection 3. Dwelling 4. Cooling 5. Opening 6. Ejection. Each stage is indispensable and needed to be set with the right parameter.

01

Clamping

02

Injection

03

Dwelling

04

Cooling

05

Opening

06

Ejection

Injection Molding Process

Ejection

The mold is ejected with a rod and ejection plate to eject the new high resistance finished part generated. Unused carrots and couriers can be recycled to be reused for subsequent production cycles.

Q

What plastics are used in injection Molding?

A

Crystalline Plastics, Amorphous Plastics, Imidized Plastics, Polyethylene (PE), Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS), Polyoxymethylene (POM), Polystyrene (PS), Resin, Nylon, Polycarbonate, Thermoplastic Rubber, Fiber Reinforce Plastic, Glass Filled Nylon, Acrylic, Polymethyl Methacrylate(PMMA), Polycarbonates (PC), High-density polyethylene (HDPE), Liquid Silicone Rubber.

Q

What are the applications of injection molding?

Q

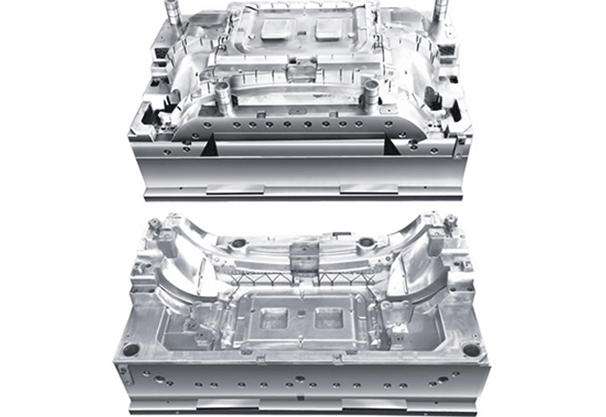

What size of parts are you able to produce?

Q

What is the distinction between injection molding and 3D prints?

Q

What are the advantages of injection molding?

Q

How much does plastic injection molding mold cost?

Send product request

Other supplier products

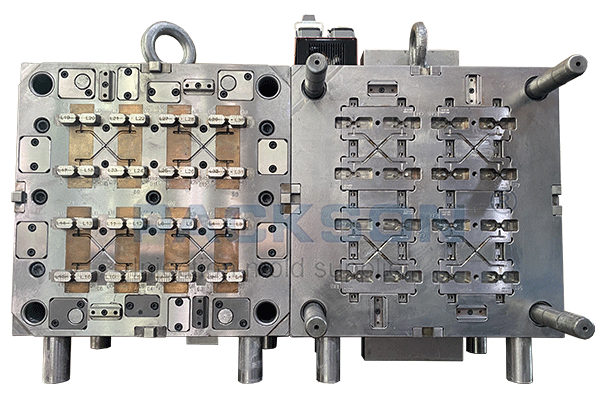

| Multi-cavities Injection Molding | Multi cavity mouldis an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity molddesign is to produce m... | |

| 2K Injection Molding | Multi-component molding is a highly efficient and cost-effective technology that enables the molding of custom plastic parts using two or three pla... | |

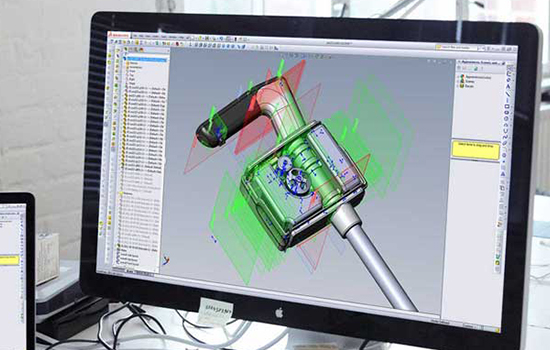

| Product Design & Development | In addition to providing moulding die design solutions, we can also provide customers with product design optimization solutions to save more cost ... | |

| Explore Packson's Injection Molding Services | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability With more than 20 years exp... | |

| One-stop Injection Molding Service Expert | One-stopCustom Molding Services For more than 15 years, Packson Mold has become an excellent manufacturer that is enabled to make parts with high ... |

Same products

| JY-160S2 Standard Plastic Injection Machine | Seller: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| Silicone Rubber Injection Molding | Seller: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | Seller: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | Seller: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | Seller: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... |