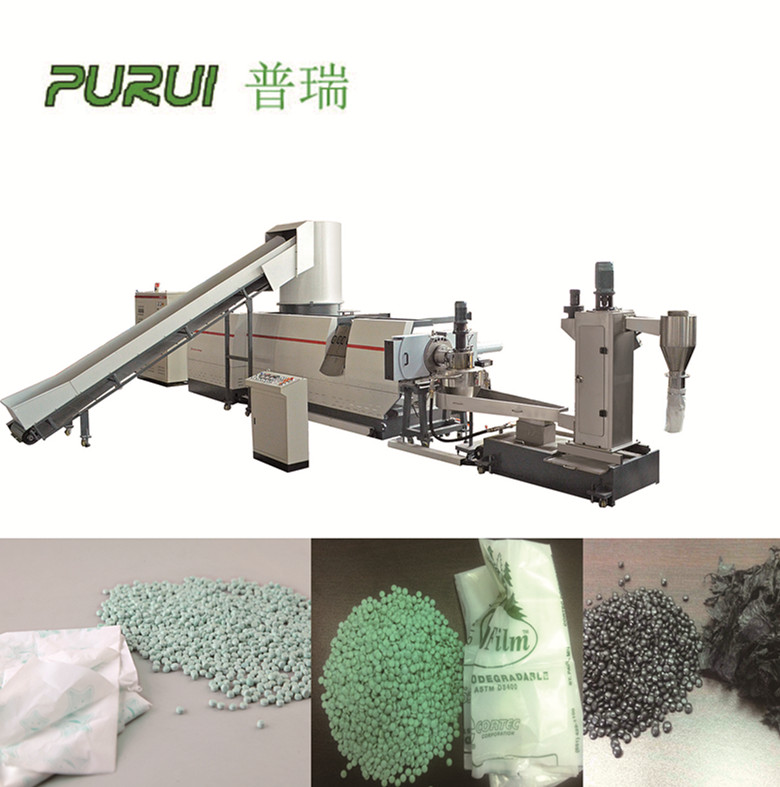

PP,PE film plastic recycling machine pelletizing line

PP,PE heavy printed film pelletizing line

1.Whatdoesthe machine do?

The machine could help you to recycle theheavly printedplastic BOPP, CPP, HDPE, LDPE,LLDPE,PET,PA,EPE,ETC.film, bags,raffia, yarn, scrapes etc.The end products is the regular plastic pellets.The L/D 42:1, with two degassing venting will largely reduce the ink and other impurity. Also the screen changer will remove the impurities. Finally the second stage will remove the remaining ink and moisture.

The material either from post industrial material or post customer material. Note please: depends on the material condition, the material should be washed or not washed.

2.Doesthe machine need large space?

The machine is small with no much space in factory. It contains one conveyor with or without metal detector, cutter compactor, extruder, degassing, pelletizing, water chute, vibration, and cenntrifugaldewatering, wind transmission and packing.

3.How does the machine work?

The machine work like these:

One person put the raw material into the belt conveyor, the metal detector detects the metal.If the metal pass, the metal detector will larm, and the belt will stop. You remove the metal the restart the metal detector. The raw material goes into the cutter compactor for cutting and compacting.The cutter compactor mountdiskwith rotory knives. It will work with the fited knives inside of the cutter compactor to crush the raw material and then the material will go into the entrance of the extruder connecting the cutter compactor. The extruder is with degassing and filter, each with the ability to remove the ink and impurities. After the raw material go out the extruder die head, there is the watering pelletizing or strand pelletizing. It will cut thematerial into the small regular pellets. Then the cutted pellets go to the centrifugal dewatering to dewater and then go to the vibration and wind tranmission channel for the next step packing.

4.Does your machine will work well on our material?

Specialised in the plastic recycling machine for more than 10 years, we have exported machine to all over the world. We have aboundant experience in the solving the plastic recycling problem. You could bring your material to our factory to test or you could visit our factory to test the machine.

5. Will the machine be reliable?

All the machine passed the CE certificate. We will list the machine material in the quotation for you check. The motor is SIEMENS BEIDE, temperature control OMRON, SIMENS frequency controlling etc.

6. How to solve the problem when the machine go wrong?

As per customer request, we offer engineering to assist install machine in customer factory. And we will offer training and maintance tecniques. Main machine guanrantee is one year except the wearing parts.is Once any problem on machine running, we will offer first reponse.

7. How is the payment item?

We accept 30% T/T payment in advance, and 70% payment T/T before shipping.

8. How to accept the machine?

Once the machine finish, customer go to our factory to check and test the machine. We will offer the test material. Once satisfy, customer pay the rest money.

Send product request

Other supplier products

| PP,PE film plastic recycling machine pelletizing line | PP,PE heavy printed film pelletizing line 1.Whatdoesthe machine do? The machine could help you to recycle theheavly printedplastic BOPP, CPP, HDPE,... | |

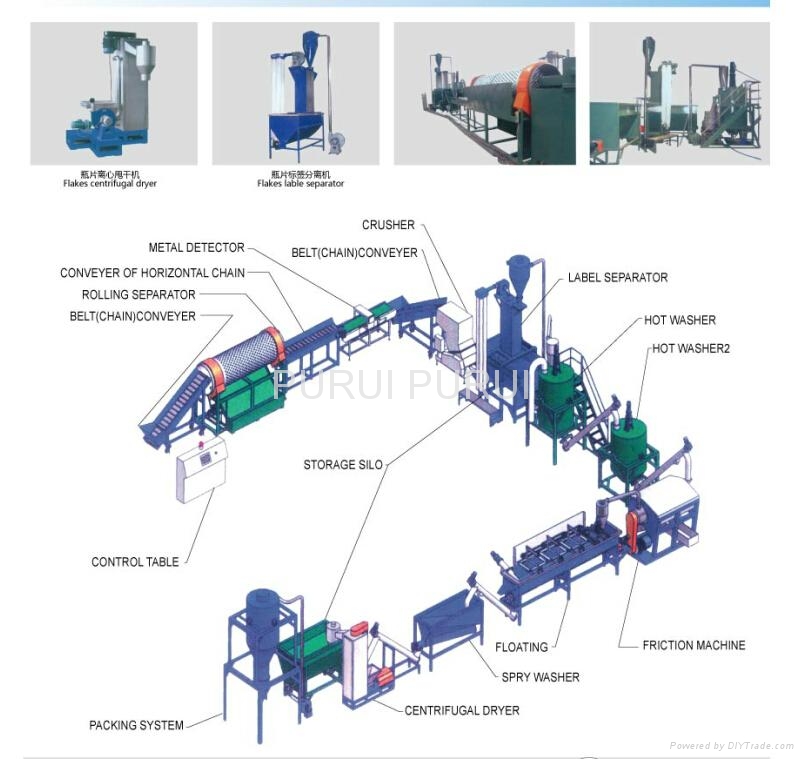

| PET bottle flakes washing line | PET bottle flakeswashing line plastic recycling machine Output: 1000-3000kg/h PET flakes quality reference table(with intelligent optical sorting)... | |

| PET bottle flakes washing line | PET bottle flakeswashing line plastic recycling machine Output: 1000-3000kg/h PET flakes quality reference table(with intelligent optical sorting)... | |

| PP,PE film plastic recycling machine washing line | Plastic PP non-woven bagswashing line washing machineOur factory has been in the plastic recycling machine for more than 10 years. With the years d... | |

| PP,PE film plastic recycling machine pelletizing line | PP,PE heavy printed film pelletizing line 1.Whatdoesthe machine do? The machine could help you to recycle theheavly printedplastic BOPP, CPP, HDPE,... |

Same products

| PET bottle recycling machine And Squeezer POSEIDON C900 | Seller: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| GREENMAX PET bottle recycling machine P-C350 | Seller: Intco Recycling GREENMAX | PET bottle recycling machinePoseidon series specializes in de-watering and compacting beverage bo... | |

| PET bottle recycling machine And Squeezer POSEIDON C200 | Seller: Intco Recycling GREENMAX | PET bottle recycling machine Poseidon series specializes in de-watering and compacting beverage b... | |

| GreenMax Foam Compactor Z-C100 | Seller: Intco Recycling GREENMAX | GreenMax Zeus C100 foam compactor isspecialized in waste foam recycling by extruding foam based o... | |

| GREENMAX EPS crusher for beads | Seller: Intco Recycling GREENMAX | GREENMAX EPS beads crusher is a recycling equipment, especially for recycling EPS/polystyrene. Di... |