Eddy Current Testing Equipment

ECT Eddy current testing used by eddy current test setis a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals to detect. It is one of the NDT non-destructive testing methods in the industry.

The principle of eddy current apparatusis that the coil with alternating current is placed on the metal plate to be measured or outside the metal, tube to be measured (see figure). The alternating magnetic field will be generated inside and near the coil, which makes the induced alternating current in the sample appear to be eddy, which is called eddy current. Under certain conditions, the current through the coil is invariable. If the coil is close to the workpiece under test, like a ship in the water, the eddy current will be induced in the workpiece. Under the influence of the eddy current, the coil current will change. Therefore, with this kind of eddy current apparatus, the defect in the workpiece can be shown by the change of coil current as the size of the eddy current varies with the defect in the workpiece.

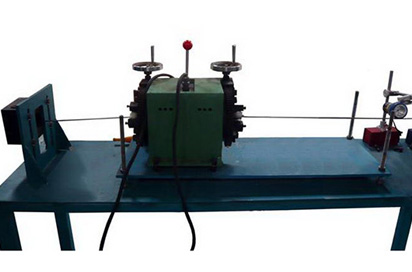

Eddy Current Testing for Tube, Bar and Wire

Eddy current testing is a non-contact testing method, which mainly uses electromagnetic field and electromagnetic induction between metals to detect.

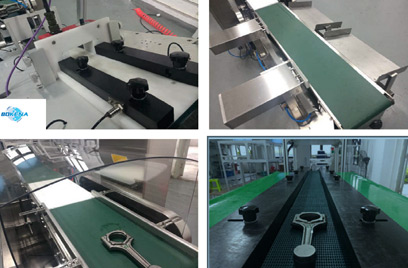

Eddy Current Testing for Auto Parts

Eddy current testing technology has been widely used in the detection of metal components in the aviation and aviation fields.

Eddy current testing equipment is our flagship product. We are one of the best eddy current test equipment suppliers in China. It contains ECT testing equipmentfor tube, bar and wire & ECT equipment for automotive parts and aviation. ECT for tube, bar and wire including BKNET-999/H Copper Tube Eddy Current Flaw Detector, GSET-551steel wire eddy current testing, BKNET-101 Automatic Eddy Current Flaw Detector, Rod Tube Rotary Eddy Current Flaw Detector ET-R-15/40/65/90, BKNET-01�2 Welded Pipe Eddy Current Flaw Detector, LGET-553 Aluminum Tube Eddy Current Flaw Detector.

ECT testing equipment for automotive parts and aviation including BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator, BKNET Series Multi-frequency and Multi-filter Eddy Current Flaw Detector, ET-F1 Engine Cylinder Bore Eddy Current Flaw Detector, GTET-02 Cylinder Liner Eddy Current Flaw Testing Machine, Steel Ball Hardness eddy current separator GQYDFX-01, GZET-01 Roller Automatic Eddy Current Flaw Testing Machine, Roller Hardness eddy current Separator GZYDFX-01, Piston Rod Eddy Current Flaw Detector HSGET-04, HSXET-02 Piston Pin Eddy Current Tester, Precision Axis Eddy Current Flaw Detector JMZET-04, Connecting Rod Hardness eddy current Sorting Machine LGYDFX-01, Hub Bearing Eddy Current Flaw Detector LGTSET-A/B, Bolt Vortex Sorter BKNFX-11, Flame Quenching Valve Rod End Hardness Eddy Current Sorter QMYDFX-01, QTXET-01 Ball Socket Eddy Current Sorter, QTXFX-01Ball Socket Hardness Eddy Current Sorter, SCPET-04 Brake Disc Eddy Current Flaw Detector, TLET-04 Camshaft Eddy Current Flaw Detector, TLZET-99 Camshaft Eddy Current Flaw Detector, Tapered Roller Online Eddy Current Flaw Detector YZGZET-01, Ring Crack and Hardness Combination Flaw Detector TQJC-02.

As one ofeddy current testing equipment manufacturers, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

There are many ndt testing equipment suppliersin China, but we are one of the best choices for you.

Send product request

Other supplier products

| Eddy Current Testing Equipment | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... | |

| Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 | During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all d... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless.... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction Using the eddy current signa... |

Same products

| Plastic Smoke Density Tester F313 | Seller: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

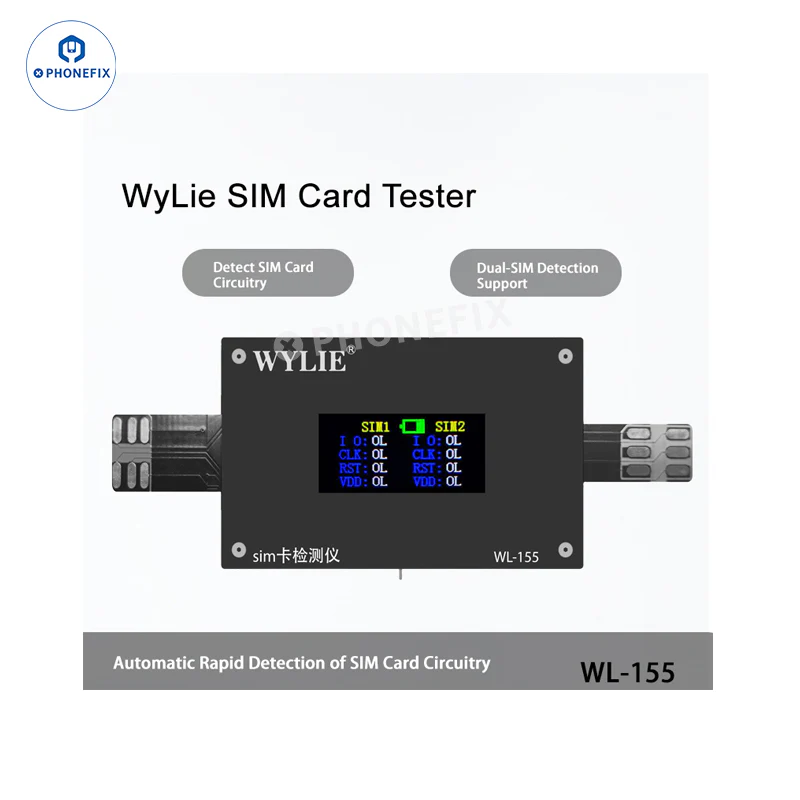

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | Seller: China PHONEFIX Technology Co., Ltd | WYLIE WL-155 SIM Card Tester is used to detect SIM card circuits and supports dual-SIM detection ... | |

| HCV1500 High-precision Voltage Sensor | Seller: Shenzhen Hangzhi Precision Electronics Co., Ltd | HCV1500 high-precision voltage sensor is a voltage sensor that can measure DC, AC, pulse and vari... | |

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... |