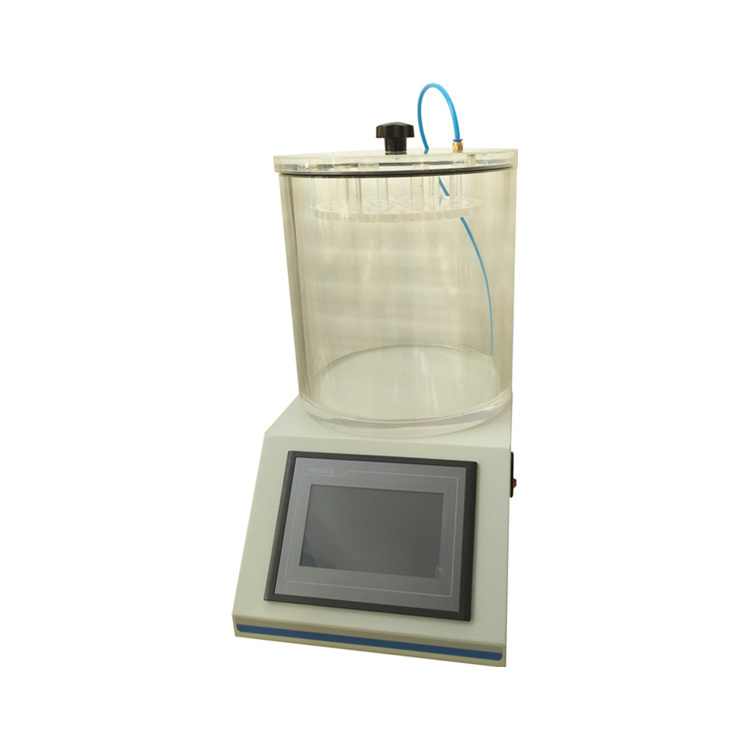

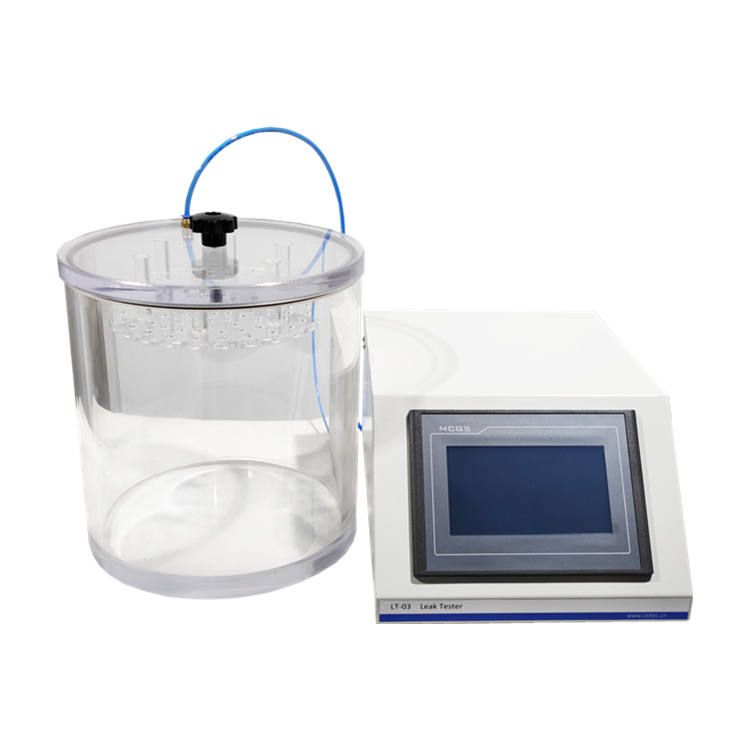

Packaging Leak Tester ASTM D3078 Vacuum Leak Tester

1. Introduction of LT-03 Leak Tester:

Cell Instruments presents the LT-03 Leak Tester, a cutting-edge solution for assessing package seal integrity. This innovative testing instrument plays a crucial role in verifying the packaging's ability to provide the necessary product protection. With a focus on industrial-level stability, the LT-03 is PLC-controlled and features an intuitive HMI touch screen operation, making it an essential tool for industries such as plastics, paper, textile, food, pharmaceuticals, toiletries, printing, and adhesives.

2. Advantages of LT-03 Leak Tester:

Industrial-level Stability: The PLC-controlled unit ensures stability, providing reliable and accurate results.

Visual Observation: The testing method relies on visual observation, offering cumulative result numbers for a comprehensive understanding.

Flexible Testing Options: The parameter-saving function allows optimization for different samples and test conditions.

Customizable Chambers: The robust and transparent chamber can be customized for various sizes and shapes, offering versatility in testing.

Multi-language Support: Optional adaptation for display in local languages enhances user accessibility.

Optional Features: The inclusion of a micro printer for sample identification and modification capability to operate with a vacuum pump for higher vacuum levels.

3. Why do you need LT-03 Leak Tester?

The LT-03 Leak Tester is an indispensable tool for ensuring the reliability of package seals. In industries where product quality and safety are paramount, assessing package seal integrity is vital. The LT-03 provides a comprehensive solution for evaluating sustainable packaging alternatives, cost-effective packaging options, and variations in production line sealing parameters.

4. What is the purpose of LT-03 Leak Tester?

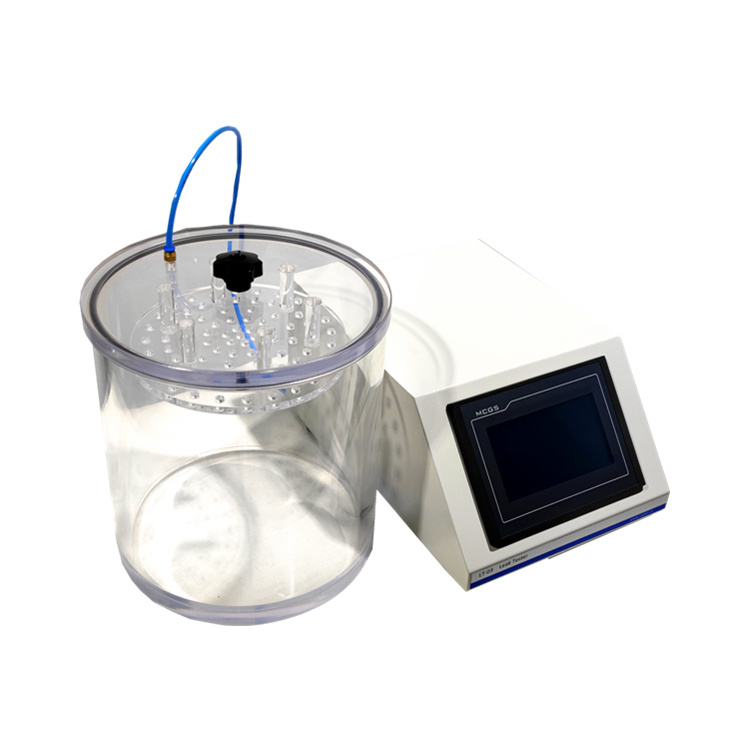

The primary purpose of the LT-03 Leak Tester is to assess the seal integrity of packages. By creating a controlled environment within a water-filled chamber, the tester extracts air to a predetermined vacuum level. Any minor leaks in the package result in the expulsion of trapped air, visually indicated by bubbles. This process ensures that packages maintain their integrity, upholding product quality and safety standards.

5. Application:

The LT-03 Leak Tester finds application in various industries, including plastics, paper, textile, food, pharmaceuticals, toiletries, printing, and adhesives. It is instrumental in evaluating sustainable packaging alternatives, cost-effective packaging options, and variations in production line sealing parameters.

6. Specifications:

Test Range: 0 to -90 KPa

Chamber: Acrylic cylinder shape

Test Space: Φ270 x H210mm (Inside Usable)

Compressed Air: 0.7MPa (Prepared by user)

Power: 110~220V, 50/60Hz

Available Chambers:

Cylindrical shapes with various required heights and diameters, such as φ270mm, φ364mm, φ464mm, etc.

Cuboid shapes with different Length (L), Width (W), and Height (H).

7. Standards:

The LT-03 Leak Tester complies with industry standards, ensuring that it meets the requirements for assessing package seal integrity.

8. Configuration:

The LT-03 Leak Tester features a PLC-controlled unit with HMI touch screen operation, a Venturi tube for stable vacuum, visual observation for cumulative results, parameter-saving function for efficiency, and optional features such as a micro printer and adaptation for local languages. Its modification capability allows operation with a vacuum pump for higher vacuum levels.

Other supplier products

All supplier products

Same products