Eddy Current Testing Equipment

Bokena is one of the most professional eddy current test equipment suppliersin China. We have been devoted to produce ect testing equipmentand ect ndtfor many years.

ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals to detect. It is one of the NDT non-destructive testing methods in the industry.

The principle of eddy current testing is that the coil with alternating current is placed on the metal plate to be measured or outside the metal, tube to be measured (see figure). The alternating magnetic field will be generated inside and near the coil, which makes the induced alternating current in the sample appear to be eddy, which is called eddy current. Under certain conditions, the current through the coil is invariable. If the coil is close to the workpiece under test, like a ship in the water, the eddy current will be induced in the workpiece. Under the influence of the eddy current, the coil current will change. Because the size of the eddy current varies with the defect in the workpiece, the change of coil current can reflect the defect in the workpiece.

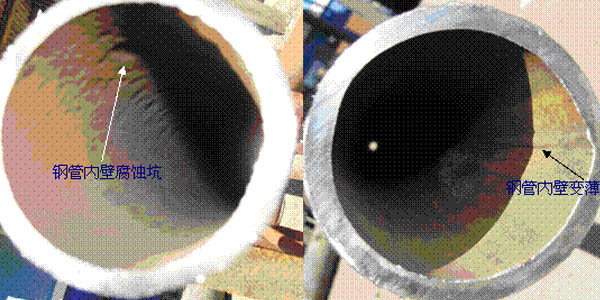

Eddy Current Testing Equipment for Tube, Bar and Wire

Eddy current testing is a non-contact testing method, which mainly uses electromagnetic field and electromagnetic induction between metals to detect. It is one of the non-destructive testing methods

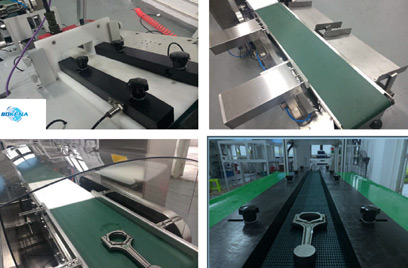

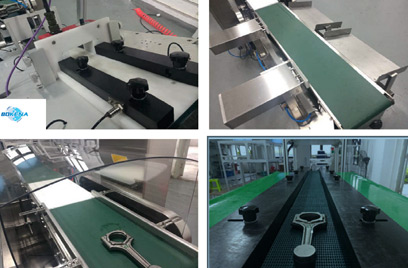

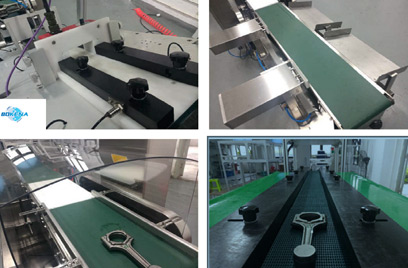

ECT For Automotive And Aerosapce

Eddy current testing technology has been widely used in the detection of metal components in the aerospace and aerospace fields. In order to ensure the flight safety of the aircraft, the relevant

Eddy current testing equipments are our flagship products, it contains eddy current testing equipment for tube, bar and wire & eddy current testing equipment for automotive parts and aerospace. Eddy current testing equipment for tube, bar and wire including BKNET-999/H Copper Tube Eddy Current Flaw Detector, GSET-551steel wire eddy current testing, BKNET-101 Automatic Eddy Current Flaw Detector, Rod Tube Rotary Eddy Current Flaw Detector ET-R-15/40/65/90, BKNET-01�2 Welded Pipe Eddy Current Flaw Detector, LGET-553 Aluminum Tube Eddy Current Flaw Detector.

Eddy current testing equipment for automotive parts and aerospace including BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator, BKNET Series Multi-frequency and Multi-filter Eddy Current Flaw Detector, ET-F1 Engine Cylinder Bore Eddy Current Flaw Detector, GTET-02 Cylinder Liner Eddy Current Flaw Testing Machine, Steel Ball Hardness eddy current separator GQYDFX-01, GZET-01 Roller Automatic Eddy Current Flaw Testing Machine, Roller Hardness eddy current Separator GZYDFX-01, Piston Rod Eddy Current Flaw Detector HSGET-04, HSXET-02 Piston Pin Eddy Current Tester, Precision Axis Eddy Current Flaw Detector JMZET-04, Connecting Rod Hardness eddy current Sorting Machine LGYDFX-01, Hub Bearing Eddy Current Flaw Detector LGTSET-A/B, Bolt Vortex Sorter BKNFX-11, Flame Quenching Valve Rod End Hardness Eddy Current Sorter QMYDFX-01, QTXET-01 Ball Socket Eddy Current Sorter, QTXFX-01Ball Socket Hardness Eddy Current Sorter, SCPET-04 Brake Disc Eddy Current Flaw Detector, TLET-04 Camshaft Eddy Current Flaw Detector, TLZET-99 Camshaft Eddy Current Flaw Detector, Tapered Roller Online Eddy Current Flaw Detector YZGZET-01, Ring Crack and Hardness Combination Flaw Detector TQJC-02.

As one of the most professional ndt testing equipment suppliersin China, we offer ndt machine. We welcome merchants from all over the worldto cooperate with our factory for mutual benefit and win-win, and jointly create a better future.

Send product request

Other supplier products

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Benchtop Magnetic Flux Leakage Testing Equipment | BKN is one of professional ultrasonic testing equipment manufacturers. We provide Magnetic Flux Leakage Testing, ndt device, ndt testingand so on. ... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Mag flux testingis a magnetic method of nondestruc... | |

| Application of Ndt Inspection Equipment | Ndt inspection equipmentis widely used in industry, such as nuclear industry, weapon manufacturing, machinery industry, shipbuilding, petrochemical... |

Same products

| RTDS121C Ceramic Uncooled Thermal Detector | Seller: IRay Technology Co., Ltd. | RTDS121C Ceramic Packaged Uncooled Infrared Detector employs a self-developed 12μm uncooled VO... | |

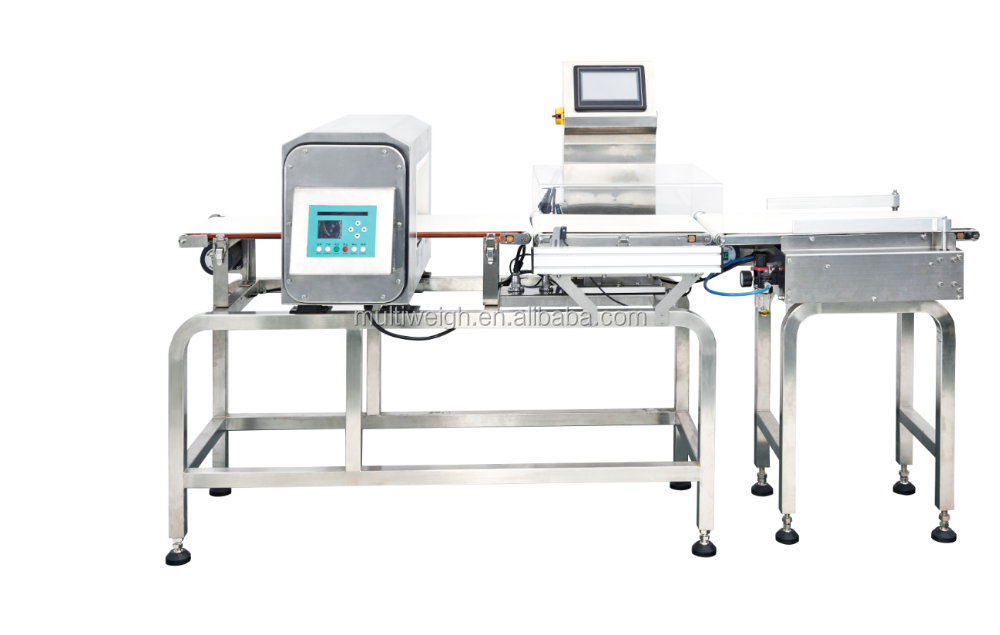

| Combined check weigher and metal detector | Seller: Guangdong Kenwei Intellectualized Machinery Co., Ltd. | Application It is widely used for food, pharmaceutical, chemical, textile, clothes, toys, rubber ... | |

| Portable Magnetic Flux Leakage Testing Equipment | Seller: Nanjing BKN Automation System Co.,LTD | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of ... | |

| MFL101 Tank Floor MFL Scanner | Seller: Nanjing BKN Automation System Co.,LTD | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from th... | |

| Magnetic Flux Leakage Testing Equipment | Seller: Nanjing BKN Automation System Co.,LTD | Electromagnetic detection is a very important non-destructive testing method and is widely used. ... |