Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near-surface of the test piece. People can detect defects by detecting changes in the leakage magnetic field.

Briefly describe the magnetization of ferromagnetic components. In the magnetic non-destructive testing, magnetization is the first step to realize the detection, which determines whether the leakage magnetic field signal can be generated, and also affects the performance characteristics of the detection signal and the structural characteristics of the detection device. Like magnetic particle inspection, magnetization is achieved by a magnetizer, including both a magnetic source and a magnetic circuit. The magnetic source and the magnetic circuit change depending on the structure of the member to be tested.

What kind of magnetization can be divided into several categories? The magnetization methods can be generally divided into five categories, namely, alternating current magnetization mode, direct current magnetization mode, permanent magnet magnetization mode, composite magnetization mode, and integrated magnetization method.

What are the characteristics of magnetic flux leakage detection technology?

Because leakage magnetic field detection uses magnetic sensors to detect defects, compared with magnetic powder, penetration and other methods, it has the following advantages:

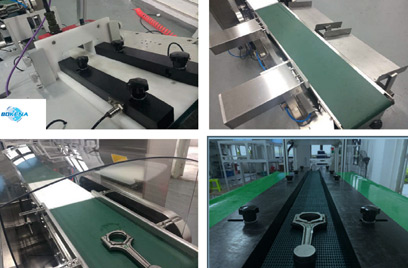

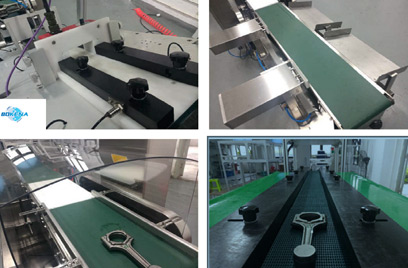

BKN's portable mfl equipmentare capable of detecting workpieces efficiently and accurately.

As one of the most professional non destructive testing equipment manufacturersin China, we offer mfl ndt. We welcome merchants from all over the world to cooperate with our factory for mutual benefit and win-win, and jointly create a better future.

Send product request

Other supplier products

| Connecting rod hardness eddy current sorting machine LGYDFX-01 | The connecting rod hardness eddy current sorting machinehas a calibration device, input compensation parameters, automatic/manual temperature compe... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testingis a magnetic method ... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKNAutomation System Co., Ltd. for makin... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Mag flux testingis a magnetic method of nondestruc... | |

| Eddy Current Testing Equipment | Bokena is one of the most professional eddy current test equipment suppliersin China. We have been devoted to produce ect testing equipmentand ect ... |

Same products

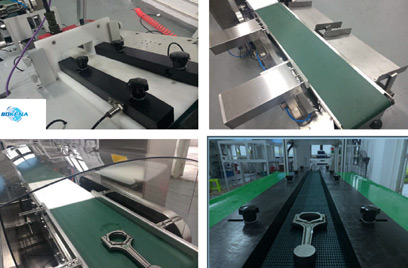

| RTDS121C Ceramic Uncooled Thermal Detector | Seller: IRay Technology Co., Ltd. | RTDS121C Ceramic Packaged Uncooled Infrared Detector employs a self-developed 12μm uncooled VO... | |

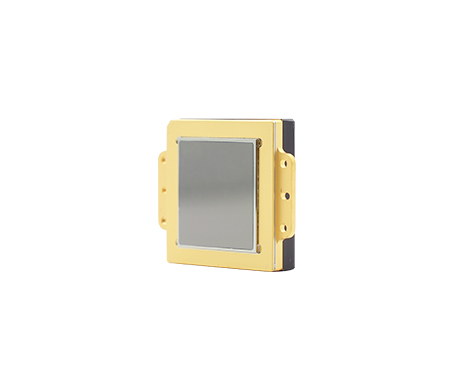

| Combined check weigher and metal detector | Seller: Guangdong Kenwei Intellectualized Machinery Co., Ltd. | Application It is widely used for food, pharmaceutical, chemical, textile, clothes, toys, rubber ... | |

| Portable Magnetic Flux Leakage Testing Equipment | Seller: Nanjing BKN Automation System Co.,LTD | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of ... | |

| MFL101 Tank Floor MFL Scanner | Seller: Nanjing BKN Automation System Co.,LTD | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from th... | |

| Magnetic Flux Leakage Testing Equipment | Seller: Nanjing BKN Automation System Co.,LTD | Electromagnetic detection is a very important non-destructive testing method and is widely used. ... |