GSET-551 Steel Wire Eddy Current Flaw Detector

GSET-551 Steel Wire Eddy Current Flaw Detector Brief

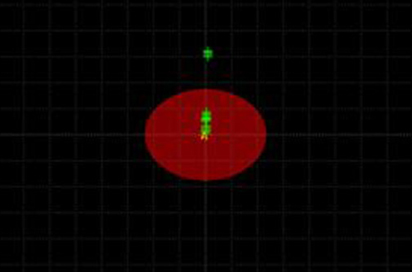

Using the eddy current signal processing method and high-performance DSP algorithm, the NDTwire rope testerdetection ability of micro-crack is as high as 0.05mm deep crack.

Using computer digital technology and "digital eddy current detection technology" to achieve high-speed data processing capabilities, detection speed can be reached to 1~500m/min. Technology can effectively suppress all kinds of interference signals. It has waveform, amplitude, phase, X-axis and Y-axis signals.

The professional "digital filtering" is adopted to effectively suppress the interference signal in the field and ensure the accuracy and stability of the detection.

Features ofGSET-551 Steel Wire Eddy Current Flaw Detector

The detector detects the minimum metal cross-sectional area change and the minimum length of the damage length corresponding to the local damage.

The detector detects the minimum metal cross-sectional area change and the damage length minimum size corresponding to the metal cross-sectional area loss.

The maximum value of the random error obtained by performing multiple consecutive measurements of the same metal cross-sectional area change in the same test sample under the same test environment and conditions within the instrument range.

Within the range of the instrument, the metal cross-sectional area of the test sample is linearly proportional to the absolute value of the maximum deviation between the measured curve of the instrument and the calibration curve fitted by the measured value of the cross-sectional area of the metal.

The value of the metal cross-sectional area loss measured by the instrument minus the actual value of the metal cross-sectional area loss within the instrument's range.

In the range of the instrument range, under the condition of the length loss of the cross-sectional area of the metal, the cross-sectional area loss of the metal on the wire rope measured by the detector is matched with the value of the loss of the cross-sectional area of a group of wire ropes measured by the instrument. The absolute value of the maximum deviation between the calibration curves.

The detector is capable of detecting the resolved minimum distance.

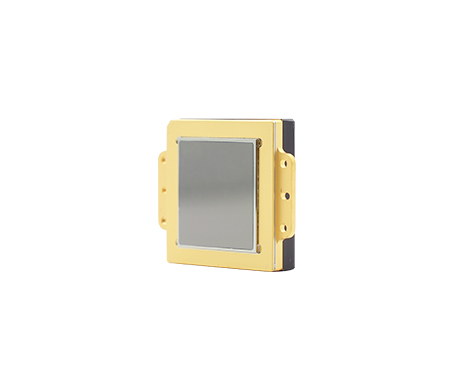

The detector can detect and display changes in metal cross-sectional area loss (LMA) on one channel, and detect and display local damage (LF) on the other channel. The detector recording device can be a computer, graphic recorder or other matches. device.

The detector cannot simultaneously detect and display metal cross-sectional area loss changes and local damage, and can only detect and display one of them. The detector recording signal device can be a computer, a graphic recorder or other matching devices.

The detector principle and composition meet the requirements of the GB/T 21837-2008 standard, and it has a detector for detecting distance display, data storage or recording function.

As one of the most professional non destructive testing equipment manufacturersin China, we offer ndt machine. We welcome merchants from all over the world to cooperate with our factory for mutual benefit and win-win, and jointly create a better future.

Send product request

Other supplier products

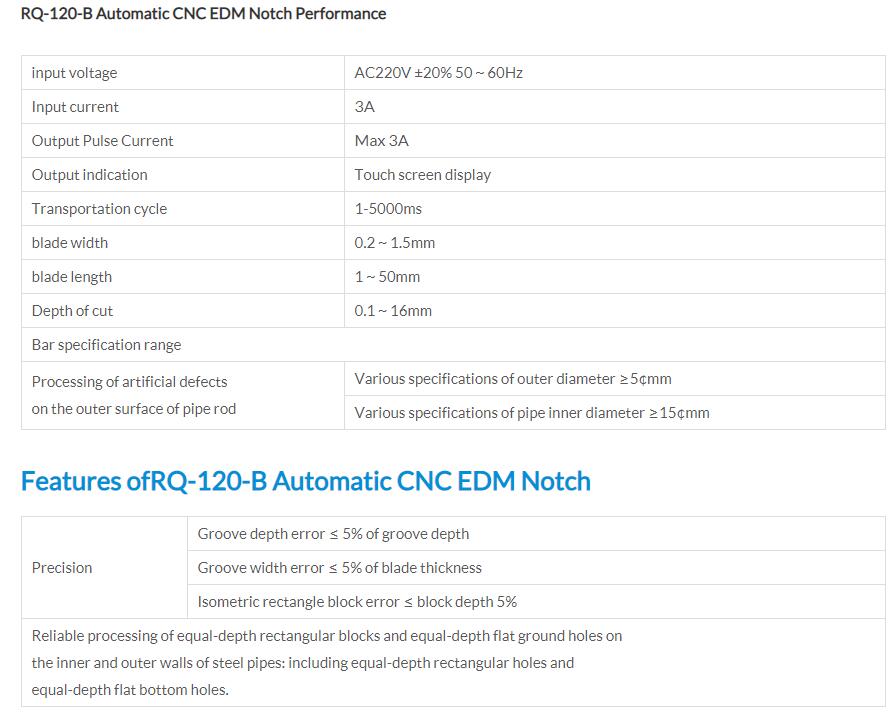

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| EDM Notch | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

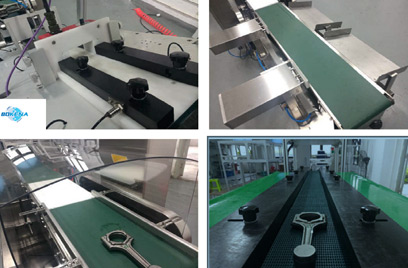

| Bolt Eddy Current Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Wireless Transmission Steel Bar Ultrasonic Flaw Detector | Steel bar is a conventional product with high density, moderate noise. The system is suitable for the automatic detection of internal and external ... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... |

Same products

| RTDS121C Ceramic Uncooled Thermal Detector | Seller: IRay Technology Co., Ltd. | RTDS121C Ceramic Packaged Uncooled Infrared Detector employs a self-developed 12μm uncooled VO... | |

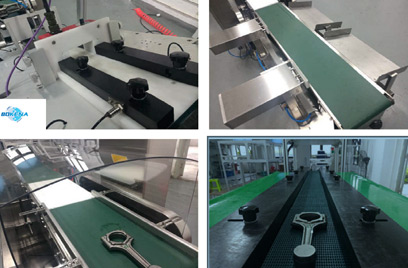

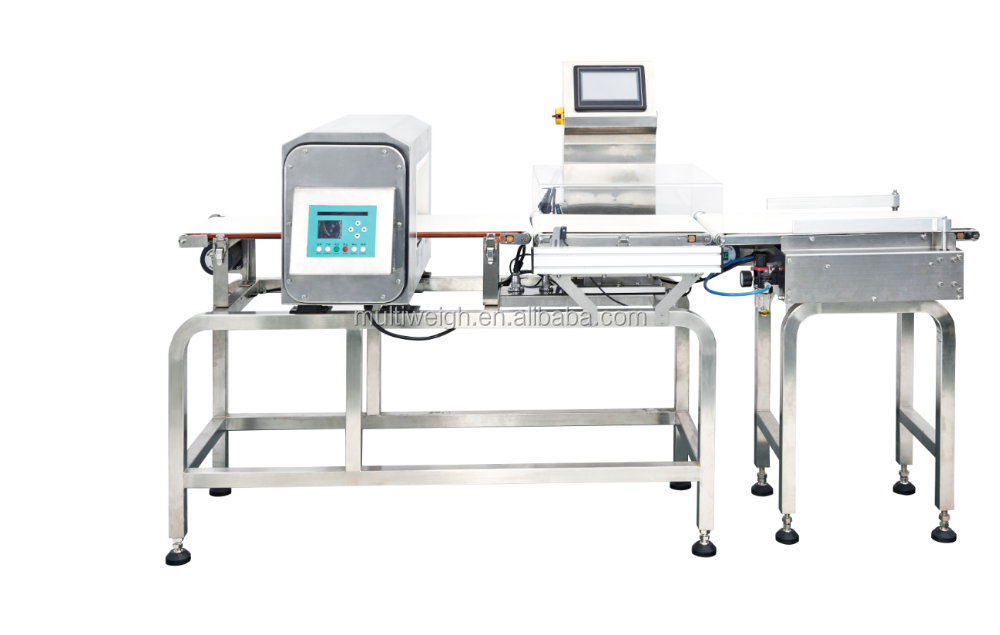

| Combined check weigher and metal detector | Seller: Guangdong Kenwei Intellectualized Machinery Co., Ltd. | Application It is widely used for food, pharmaceutical, chemical, textile, clothes, toys, rubber ... | |

| Portable Magnetic Flux Leakage Testing Equipment | Seller: Nanjing BKN Automation System Co.,LTD | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of ... | |

| MFL101 Tank Floor MFL Scanner | Seller: Nanjing BKN Automation System Co.,LTD | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from th... | |

| Magnetic Flux Leakage Testing Equipment | Seller: Nanjing BKN Automation System Co.,LTD | Electromagnetic detection is a very important non-destructive testing method and is widely used. ... |