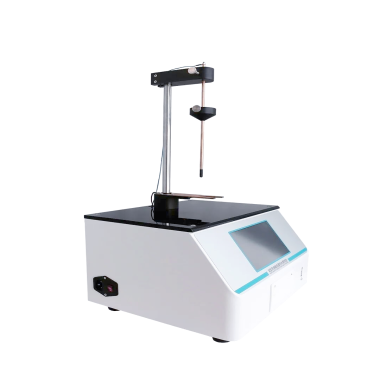

Aluminum Ointment Tube Toughness Tester

The ductility tester for aluminum tubes is a device specifically used to detect the ductility indicators of packaging materials such as aluminum soft tubes. The following is a detailed description of its main uses, compliance standards, and technical parameters:

Main Uses

The main purpose of the ductility tester for aluminum tubes is to evaluate the deformation and recovery ability, that is, the ductility, of packaging materials such as aluminum soft tubes under external forces. Through testing, we can understand the performance of aluminum tubes when subjected to external forces such as extrusion and bending during transportation, storage, and use, thereby ensuring the safety and integrity of products. This is particularly important for industries such as medicine, cosmetics, glue, and toothpaste. As the main packaging material for products in these industries, the ductility of aluminum soft tubes directly affects the product's user experience and market competitiveness.

Compliance Standards

The design and manufacture of the ductility tester for aluminum tubes usually comply with a series of national and international standards to ensure the accuracy and reliability of test results. Among them, common standards include YBB00162002 - 2015 Aluminum Pharmaceutical Soft Tubes, etc. These standards specify in detail the test methods for the ductility of aluminum tubes, specimen preparation, test conditions, etc., providing a unified standard for the use of the tester.

Technical Parameters

- Measurement Range: Usually applicable to aluminum soft tubes with an aluminum tube diameter between 10 and 45mm (some devices also cover the range of 8 - 45mm) and the tube length within a certain range. This range covers most common aluminum tube specifications, giving the tester wide applicability. - Gate Plate Weight: The gate plate is a key component in the tester for applying pressure, and its weight is usually precisely controlled within the range of 70g±1g to ensure the consistency and accuracy of testing. - Testing Accuracy: Modern ductility testers for aluminum tubes are usually equipped with a high - precision measurement system, which can accurately quantify the degree of deformation of aluminum tubes under external forces. The testing accuracy is relatively high. For example, the current measurement accuracy can reach ±0.1mA (the specific accuracy may vary depending on the device). - Automation Level: Some advanced ductility testers for aluminum tubes adopt automated and intelligent technologies, making the testing process more convenient and efficient. One - click operation, automatic timing, and data recording functions greatly reduce the burden of operators and improve the accuracy and traceability of test results. - Appearance Dimensions and Weight: The appearance dimensions and weight of the tester may vary depending on the model and brand, but it is usually designed to be compact and portable. This enables the tester to be used in different production sites and laboratories, improving the flexibility and convenience of testing. - Working Environment: To ensure the normal operation of the tester and the accuracy of test results, it usually needs to be used in a certain working environment. For example, the working temperature is between 23°C±2°C, and the relative humidity does not exceed 80% (without condensation). These working environment requirements help maintain the stability and reliability of the equipment.

Send product request

Other supplier products

| Rain Tester丨Rain Test Machine | Standard AATCC 35: Water Resistance: Rain Test for Fabrics BS EN ISO 22958: Textiles – Determination of Resistance to Water Penetration &nd... | |

| E-bike chassis dynamometer test machine | Meet the standard: EN 15194 ISO 4210 UL 2849 Product Introduction: Electric bicycles are complex systems involving mechanical, electrical, and... | |

| Digital display electronic ink viscosity meter | How it works: The working principle of the digital display electronic ink viscosity meter is based on two tin (usually a metal roller and a rubber... | |

| Xenon Light Fastness Test Chamber | Features and Benefits 1.Full-Spectrum Xenon Lamp Xenon arc lamps emit a continuous spectrum from UV to visible and infrared, closely simulating... | |

| Metal ring friction and wear testing machine | Evaluate the wear resistance of the material: By simulating the friction process, real-time monitoring of friction, temperature, wear and other pa... |

Same products

| Plastic Smoke Density Tester F313 | Seller: Standard International Group (HK) Limited | The F313 Plastic Smoke Density Tester is a precision instrument designed to measure the specific ... | |

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... | |

| Furniture flammability tester | Seller: Qinsun Instruments Co., LTD | Product details Furniture flammability tester is mainly used to test the combustion performance ... |