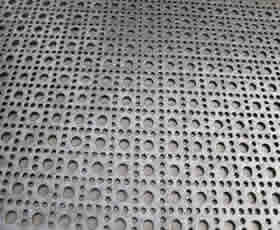

Aluminum Perforated Panel

Perforated aluminum panel has a strong resistance to corrosion due to an oxide skin formed in reaction with the atmosphere. It is a relatively light metal compared to metals such as steel, nickel, brass, and copper and is rather malleable. It can have a wide variety of surface finishes and is highly reflective to heat and light. For most applications, perforated aluminum sheets need no protective coating but are often anodized to improve color and strength.Perforated sheet aluminum is extremely useful at low-temperatures. At subzero temperatures its strength increases while retaining ductility. At temperatures over 400F aluminum alloy sheets tend to lose some of their strength.

Other supplier products

|

|

Perforated Screen |

Perforated metal screens are hard-working tools necessary components to do everything from sizing to controlling materials, such as in Grain Dryers... |

|

|

Electro galvanized sheet |

Electro galvanized steel sheets in coils:

JIS G3313, Specification (commercial quality).

Zinc coating: top/back+20 gr per sq.meter.

Chromated & ... |

|

|

Perforated Metal Sheet |

Galvanized Perforated metal sheet specifications:

Thickness : 0.75MM

Wide : 94MM

Length: 1720MM

Holes: 8MM diameter

Finished: Hot dipped galvanize... |

|

|

Perforated Wall |

Strong and function, with lightweight features, perforated metal walls are smart, efficient choices.

Designers use perforated metal to make more o... |

|

|

Perforated Panel |

Perforated panel is widely used in many fields for its variety sections and colors, which is a kind of perforated metal. We can serve all types of ... |

All supplier products

Same products