Jaw Crusher

1) Introduction to the Jaw crusher:

Jaw Crusher is mainly used to crush kinds of mining stones primarily, and the largest compression resistance of the material is 320MPa. The jaw crusher is widely used in stone mining, metallurgy industry, building material, highway, railway, and chemical industry.

2) Working Principle of Jaw Crusher:

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

3) Jaw Crusher Main Features and Benefits:

1. Flexible capacity and high reliability

2. Simple structure and easy maintenance, jaw crusher mainly consists of two jaws

3. Over-loading protection, jaw crusher has toggle plate to protect it.

4. Stable performance, low operating cost

5. High crushing ratio which can reach 4-6, also high resistance to friction, abrasion and compression with longer operating life span

4)Jaw Crusher Installation Instructions:

1. jaw crusher is installed by the factory, the user should be checked after the receipt of the jaw crusher machine and eliminate the various problems arising from transport, and then install it.

2. rack installation, the vertical plane at the end of the level of tolerance of 0.5mm / m, the horizontal level degrees (measured on the spindle) Tolerance of 0.15 mm / m.

3. comprehensive inspection before starting the jaw crusher machine. The fastening of the fixed parts, each part of the ubrication as well as V-belt tension level is to check the suitability of the like should be the focus.

4. Check the overall circuit after cuting off jaw crusher switch, and a clear sign hanging switch.

Send product request

Other supplier products

| Coal Mill | The Application and Usage Range: Coal mill is major equipment of cement plant and used for drying and grinding coal. The equipment is mainly consi... | |

| Mobile Crushing Station | Introduction to the Mobile crushing station: Mobile crushing station is a new rock crushing equipment researched and developed by our factory. It ... | |

| PCL Sand Making Machine | Introduction to PCL Sand Making Machine: Sand Making Machine (namely PCL vertical shaft impact crusher) is of high-power and low-consumption, whic... | |

| Ball Mill | Introduction to the Ball Mill: The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making ... | |

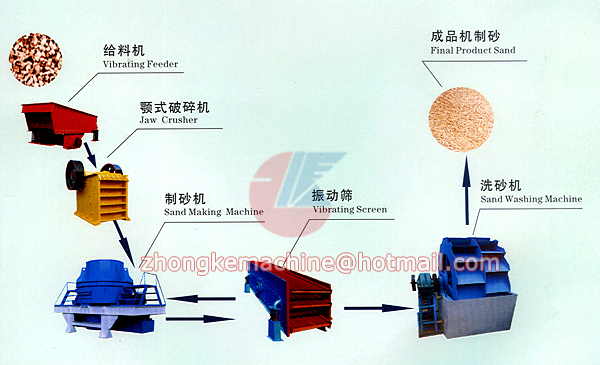

| Sand-making Production Line | Brief introduction of the sand-making production line: The raw materials are first put into elementary-crushing machine for crush, then the belt c... |

Same products

| 2-in-1 Shimmer Eyeshadow Stick & Eyeliner Pencil | Seller: Zhejiang Meixi Cosmetics Co., Ltd. | Dual-Use Design Can be applied as a shimmer eyeshadow for full eyelid coverage or as an eyeliner ... | |

| 99.5% high-purity chromium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | Chromium carbide powder has excellent wetting properties and is firmly bonded to metal substrates... | |

| Carbonitride powder for plastic modification | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The particle morphology of this powder can be controlled, and it can be made into spherical, near... | |

| Titanium carbide hard alloy drive wheel accessory | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This guide wheel is customizable with various groove geometries—including V-shaped, U-shape... | |

| Industrial titanium carbide alloy drive wheels | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This guide wheel can be customized with various slot shapes according to the specifications of wi... |