Titanium carbide guide wheels for alloy tube rolling

The installation holes of the guide wheel have high precision, and the fit clearance with the shaft can be controlled within 0.005-0.01mm, ensuring no shaking during rotation and improving the guiding accuracy. Its maintenance cost is low, and it does not require frequent lubrication. Only regular cleaning of surface impurities is needed, making it suitable for continuous operation of automated production lines. In the production of metal wire mesh, guide wheels can ensure the uniformity of the mesh holes of the wire mesh, keeping the error within 5% and meeting the strict requirements of filter materials.

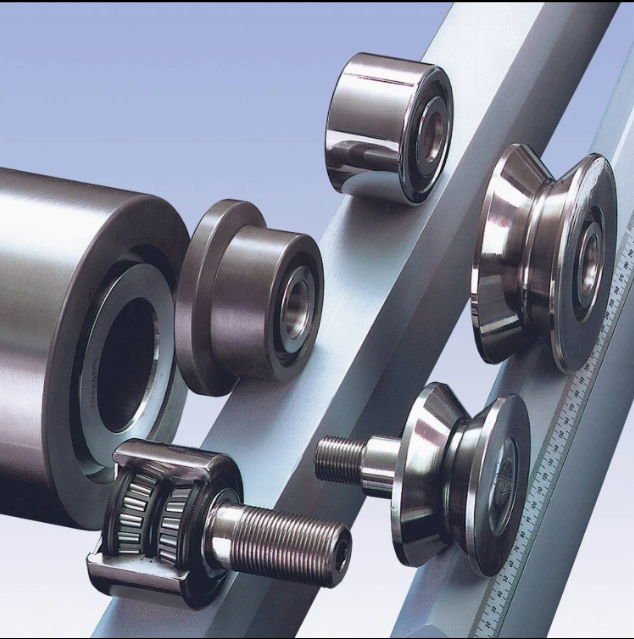

Other supplier products

|

|

High precision tantinium carbide guide wheel guide roller |

For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable part of wires export in the wires rolling process, ... |

|

|

Chromium carbide powder for cemented carbide |

Chromium carbide powder is silver-grey to grey-black in colour, with fine and uniform particles, the particle size is mostly distributed in the m... |

|

|

High-quality raw material ratio titanium carbide round bar |

Titanium carbide alloy round bar is a high-performance material product made of titanium carbide as the base, by adding metals, ceramics and othe... |

|

|

Corrosion-resistant carbide guide wheel guide roller |

For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable part of wires export in the wires rolling process... |

|

|

Titanium Carbide Based Steel Bonded Guide Wheel for Steel Rolling Wire |

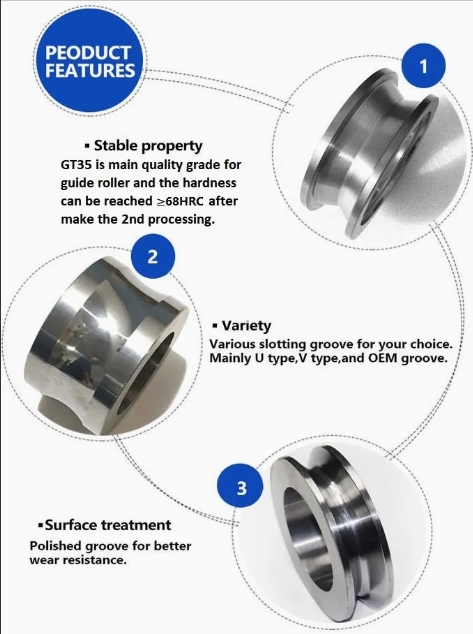

1. Product Introduction

Guide roller is a metallurgical rod guide roller, which is the main consumption spare part in the high-speed wire finishing... |

All supplier products

Same products