Industrial titanium carbide rods for precision molds

Compared with traditional high-speed steel bars, the cutting speed of hard alloy titanium carbide round bars can be increased by 3 to 5 times, which can significantly shorten the processing time in mass production. Its microstructure is uniform, and the grain size can be controlled below 1μm, ensuring consistent performance in all parts of the bar and avoiding tool failure caused by uneven material. In the mold industry, the cold stamping die inserts made from it have a service life 50 to 100 times that of steel inserts, which can significantly reduce the replacement frequency and production costs. Titanium carbide round rods of cemented carbide are high-performance rods made by powder metallurgy process, with titanium carbide as the main hard phase and cobalt or nickel as the binder phase. Its hardness is as high as over HRC85, and its wear resistance far exceeds that of ordinary steel. Even in high-temperature environments above 500℃, it can still maintain stable performance. This round bar has extremely high dimensional accuracy, with a diameter tolerance that can be controlled within ±0.01mm and a surface roughness as low as Ra0.02μm. It is highly suitable for manufacturing precision cutting tools, mold cores, etc. When processing difficult-to-cut materials such as stainless steel and titanium alloys, the tool life made of it is 10 to 20 times that of high-speed steel tools, which can significantly improve production efficiency.

Send product request

Other supplier products

| Nano grade titanium carbide alloy round bar | 该圆棒的生产工艺极其严谨,从碳化钛粉末纯度的控制(纯度≥99.5%)到烧结温度的精确调控(约1500℃),每一个环节都影响着最终的性能。成品尺寸稳定性极佳,在-50℃至300℃的温度变化下,热膨胀系数仅为6×10-⁶/℃,远低于金属材料,确保了精密工具在不同环境下的精度。它广... | |

| Glass Processing Hard Carbide Titanium Alloy Guide Wheel & Roller | For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable part of wires export in the wires rolling process, ... | |

| Composite chromium carbide powder | The main methods for preparing this powder include the electric arc furnace method and the carbothermal reduction method. Among them, the powder pr... | |

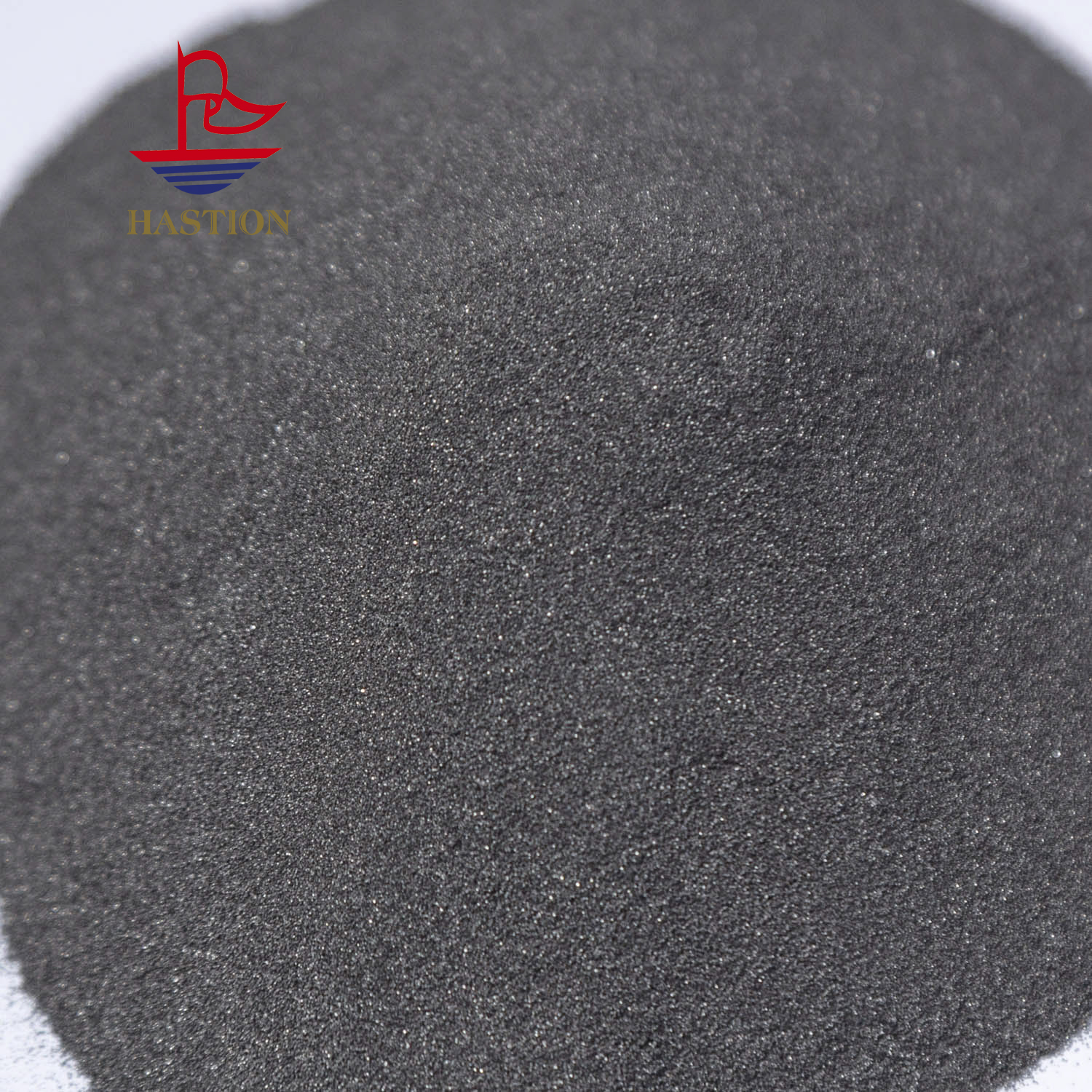

| Sintered reactive high titanium carbide powder | Titanium Carbide powder is a grey-black high hardness ultra-fine powder with the chemical formula of TiC, which has both metal and ceramic properti... | |

| Stable and reliable titanium carbide hard alloy round bars | The production process of this round bar is extremely strict, from the purity control of titanium carbide powder (purity ≥99.5%) to the precise ... |

Same products

| 3D printing spherical titanium carbide powder | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This batch of titanium carbide powder (TiC) has a purity of over 99.5%, with a particle size cont... | |

| Titanium carbide hard alloy drive wheel - Specialized | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | The titanium carbide (TiC) guide wheel is fabricated via high-temperature powder metallurgy sinte... | |

| Industrial guide wheels, titanium carbide wear-resistant alloy | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonized titanium (TiC) guide wheel is formed by high-temperature sintering of 99.5% pure ... | |

| Unfinished bar stock - heat treatable | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This high-purity titanium carbonitride (TiCN) round bar is fabricated via hot-pressing and sinter... | |

| Steel-based titanium carbide hard alloy round bar | Seller: Zhuzhou Hastion High-Tech Materials Co.,Ltd. | This carbonitride round bar (TiC) is formed by hot-pressing and sintering 99.5% high-purity carbo... |