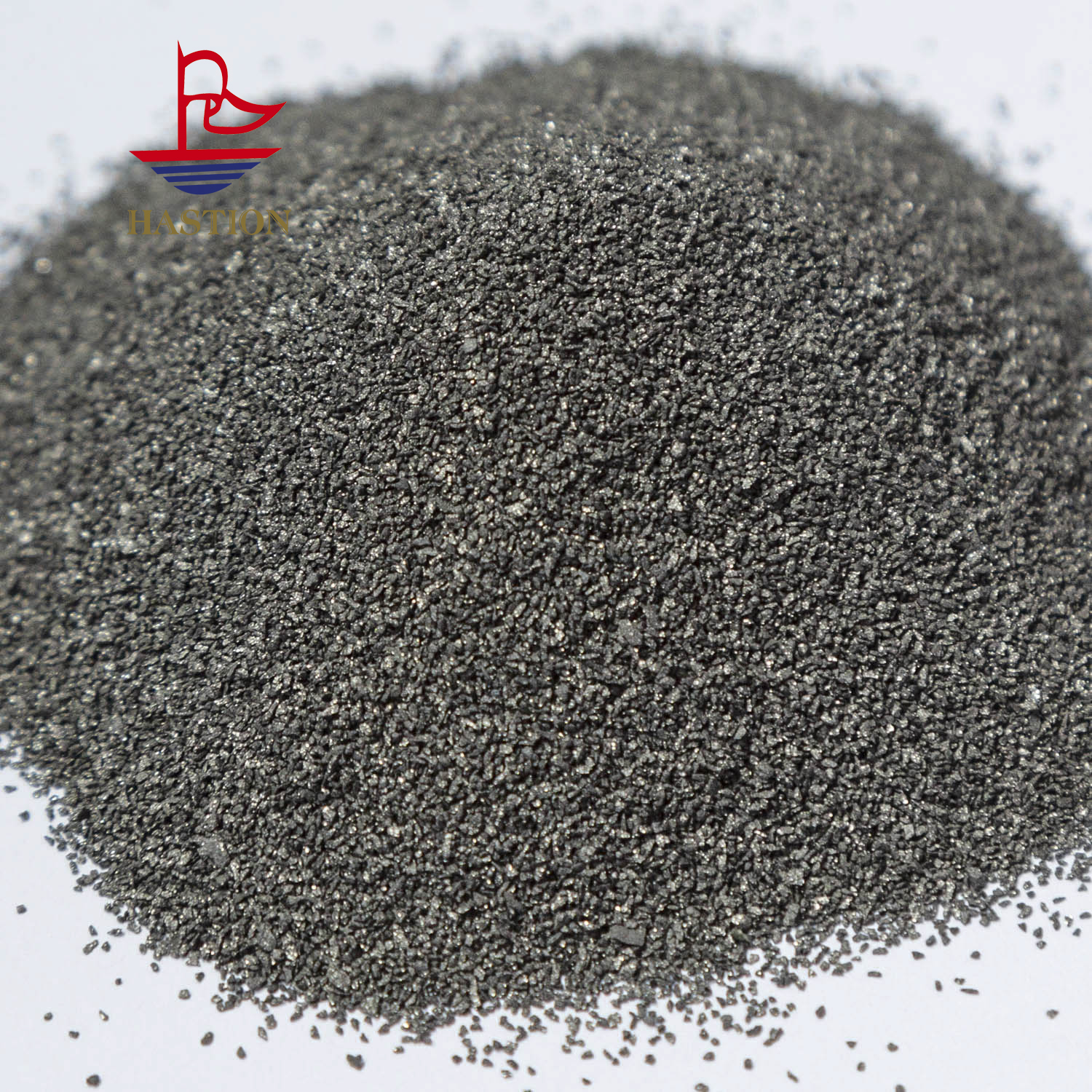

Wear-resistant composite material chromium carbide powder

Chromium carbide powder is a grayish-black powder with a melting point of approximately 1890℃ and a Mohs hardness of 8.5. It features excellent wear resistance and oxidation resistance, and is an important raw material for preparing wear-resistant coatings and hard alloys. The powder purity can reach over 99%, with a chromium content of ≥75% and a carbon content of 10-15%. The particle size can be controlled within 1-10μm, making it suitable for various sintering and spraying processes. In the steel industry, applying it to the surface of rolls through plasma spraying technology can extend the service life of the rolls by 3 to 5 times and reduce the rolling cost. This chromium carbide powder is dark grayish black in color, with a particle size of 20-50μm. It has outstanding high-temperature stability and maintains stable performance below 800℃. By surfacing and cladding the air inlet of metallurgical blast furnaces and the surface of hot rolling mill rolls, the formed cladding layer is wear-resistant and resistant to high-temperature oxidation, which can reduce the maintenance frequency of high-temperature operation equipment and ensure continuous production.

Other supplier products

|

|

Titanium carbide hard alloy guide wheels with stable performance from -50℃ to 500℃ |

Hard alloy titanium carbide guide wheels have excellent impact resistance. When the wire is suddenly tensioned or broken, they are not prone to cra... |

|

|

The hard alloy guide wheel is made of titanium carbide |

This type of guide wheel can be customized with various groove profiles tailored to the specific dimensions and types of wire or pipe, including V-... |

|

|

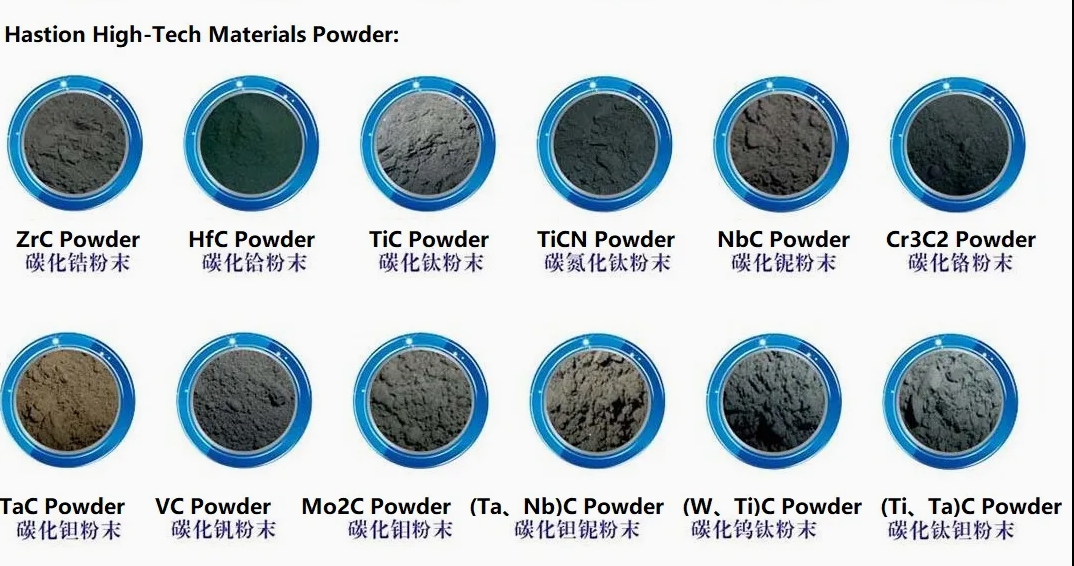

Support particle size, purity and precise control of chromium carbide powder |

Chromium carbide powder is often irregular grayish-black particles with a particle size of 10-40μm, a purity of ≥98%, and a free carbon conte... |

|

|

Chromium carbide powder with excellent fluidity |

The powder has a high hardness, with a microhardness of up to 2200HV. The hardness of the wear-resistant coating prepared from it can reach over HR... |

|

|

Steel-bonded hard alloy round bar, TiC hard phase, steel bonding phase |

Compared with conventional high-speed steel bars, carbide titanium round bars enable a 3–5× increase in cutting speed, thereby substant... |

All supplier products

Same products